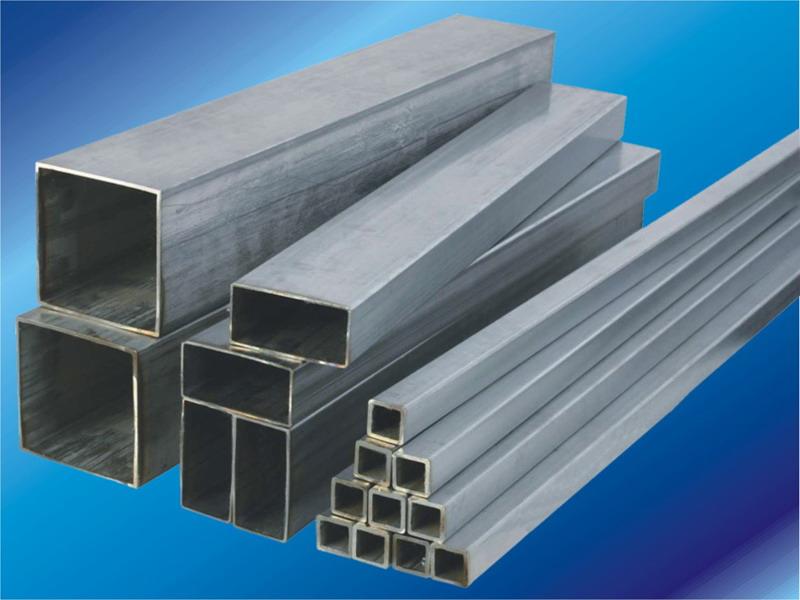

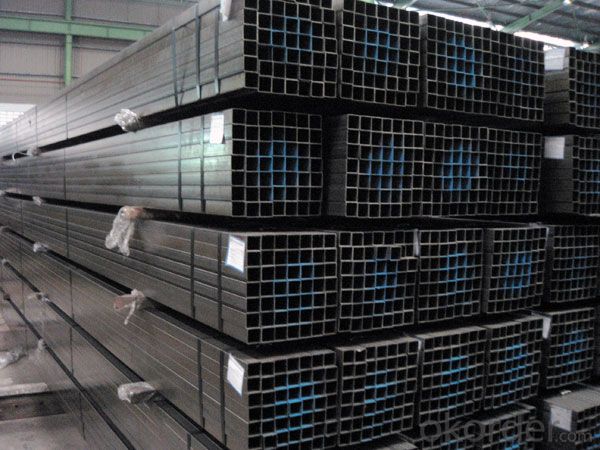

Hollow Section with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Hollow Section Description:

Hollow section is a type of metal profile with a hollow tubular cross section. Hollow section, especially rectangular sections, are commonly used in welded steel frames where members experience loading in multiple directions. Square and circular hollow section have very efficient shapes for this multiple-axis loading as they have uniform geometry along two or more cross-sectional axes, and thus uniform strength characteristics. This makes them good choices for columns. They also have excellent resistance to torsion. Hollow section can also be used as beams, although wide flange or I-beam shapes are in many cases a more efficient structural shape for this application. However, the hollow section has superior resistance to lateral torsional buckling.

2. Main Features of the Hollow Section:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3. Hollow Section with Different Specifications Images:

4. Hollow Section Specifications:

| Standard: | JIS, GB, DIN, ASTM JIS G3445-2006, JIS G3444-2006, JIS G3446-2004, JIS G3441, GB/T 8163-1999, GB/T 8162-1999, DIN EN 10216-1-2004, DIN EN 10217-1-2005, DIN EN 10305, ASTM A106-2006, ASTM A53-2007, ASTM A789-2001, ANSI A213-2001, ASTM A179-1990 |

| Grade: | 10#-45#, Cr-Mo alloy, Mo 10#, 20#, 45#, 15CrMo, 12CrMo, 13CrMo44, 12CrMo195, 16Mo, 16mo3 |

| Thickness: | 1 - 50 mm |

| Section Shape: | Square |

| Outer Diameter: | 15*15---80*80 |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Structure Pipe |

| Technique: | Hot Rolled |

| Surface Treatment: | Copper Coated |

| Certification: | API |

| Special Pipe: | Thick Wall Pipe |

| Alloy Or Not: | Non-alloy |

Specifications

high quality and low peice

quick delievry

in stock

produced by own factory

authentication:CANS CNAB IAF PAC CEC

- Q:Can steel pipes be used for cooling systems?

- Steel pipes are a viable option for cooling systems. They are frequently employed in different scenarios, such as cooling systems, because of their robustness, strength, and ability to withstand high temperatures and pressure. Industrial cooling systems, in particular, benefit from steel pipes due to the harsh environmental conditions and corrosive fluids they often encounter. Moreover, steel pipes possess outstanding heat conductivity, which facilitates efficient heat transfer, rendering them a dependable choice for cooling purposes. Furthermore, steel pipes can be easily tailored, joined, and adjusted to fulfill specific cooling system needs. Nevertheless, it is crucial to ensure that the steel pipes utilized are adequately coated or insulated to prevent corrosion and minimize heat dissipation.

- Q:How are steel pipes used in the manufacturing of solar power systems?

- Steel pipes are commonly used in the manufacturing of solar power systems for various purposes. They are used as structural supports for solar panels, providing stability and durability. Additionally, steel pipes are often utilized for the transportation of fluids such as water or heat transfer fluids, enabling the efficient circulation of these substances within the solar power system.

- Q:Fastener type steel pipe scaffold steel pipe wall thickness

- The scaffold steel pipe shall be made of 48.3 * 3.6 steel tube. The maximum mass of each steel tube shall not be greater than 25.8kg.Fastener type steel pipe scaffold: for building construction and build, bear the load by the fastener and steel pipe and other scaffolding and support frame, collectively referred to as scaffolding. The fastener is a fastening piece which is fastened by bolts.

- Q:How are steel pipes used in fire protection systems?

- Fire protection systems rely on the inclusion of steel pipes, which serve as an essential component for the distribution of water and fire suppressants within buildings. These pipes are renowned for their robustness, longevity, and ability to endure extreme temperatures, rendering them optimal for withstanding the harsh conditions associated with fires. Within fire protection systems, steel pipes are commonly utilized to establish an interconnected network of pipes responsible for supplying water to sprinkler heads or fire hydrants throughout a building. This network guarantees that water is readily accessible to suppress or extinguish fires during emergencies. One of the primary advantages of steel pipes in fire protection systems is their capacity to withstand the elevated pressure and flow rates necessary for effective fire suppression. Steel pipes can handle forceful water flow with ease, enabling prompt and efficient distribution of water to affected areas, thereby aiding in the control and extinguishing of fires in the shortest possible time. Additionally, steel pipes possess an inherent resistance to corrosion, a crucial attribute for preserving the integrity of fire protection systems over time. Corrosion has the potential to weaken pipes, leading to leaks or complete failure, which can prove catastrophic during a fire incident. However, steel pipes possess an extended lifespan and require minimal maintenance when compared to other pipe materials, ensuring the longevity and dependability of the system for many years to come. Moreover, steel pipes are frequently selected for use in fire protection systems due to their fire-resistant properties. Steel inherently possesses the ability to withstand high temperatures without deformation or compromising its structural integrity. This characteristic is of utmost importance in fire protection systems, as it enables the pipes to remain intact and continue delivering water even amidst a fire, ensuring the safety of occupants and minimizing damage to the building. In conclusion, steel pipes hold a pivotal role in fire protection systems by guaranteeing the reliable and efficient distribution of water or fire suppressants. Their strength, durability, resistance to high temperatures, and corrosion resistance make them the ideal choice for effectively combating fires and safeguarding lives and property.

- Q:What is the composition of steel pipes?

- Steel pipes are primarily composed of iron and carbon, with small amounts of other elements such as manganese, silicon, and sulfur.

- Q:What are steel pipes made of?

- Steel pipes are made of a strong and durable alloy known as steel, which is primarily composed of iron and carbon, along with small amounts of other elements such as manganese, silicon, and sulfur.

- Q:Are steel pipes suitable for transporting chemicals?

- Yes, steel pipes are suitable for transporting chemicals. Steel pipes have excellent strength and durability, making them capable of handling various corrosive chemicals and maintaining their structural integrity. Additionally, steel pipes can withstand high pressure and temperature, making them a reliable choice for chemical transportation.

- Q:How to distinguish seamless pipe and welded pipe?

- If there is a weld seam in the fracture surface, whether it is inside or outside the pipe, then it is the welded pipe

- Q:A333gr6 steel pipe and domestic material of the same?

- The SA333 standard in ASME (cryogenic seamless and welded nominal steel tubes), so A333-6 is a representation of the United States, followed by many countries.

- Q:What is the difference between steel pipes and FRP pipes?

- Steel pipes and FRP (Fiberglass Reinforced Plastic) pipes differ in their material composition, properties, and applications. While steel pipes are made from steel, FRP pipes are composed of a combination of resin and fiberglass. Steel pipes are known for their high strength and durability, making them suitable for heavy-duty applications such as transporting oil, gas, and water. On the other hand, FRP pipes are lightweight, corrosion-resistant, and have excellent chemical resistance, making them ideal for applications where corrosion is a concern, such as in the chemical industry or in sewage systems. Furthermore, FRP pipes offer better insulation properties and are easier to install due to their lighter weight. Overall, the choice between steel pipes and FRP pipes depends on the specific requirements and conditions of the application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hollow Section with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords