Hollow decking wpc decking floor outdoor tile wood plastic composite decking wpc

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood-Plastic Composite (WPC) floor accessory is manufactured from a combination of plastic, natural fiber and some additives using special equipments. It mixes natural fiber and plastic perfectly to keep the natural impression of wood but with rich colors of plastic. It has gradually replaced wood and plastic, getting widely used in more and more fields.

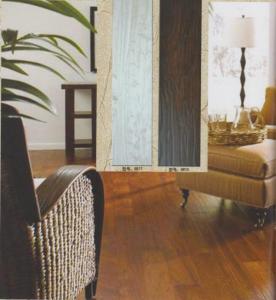

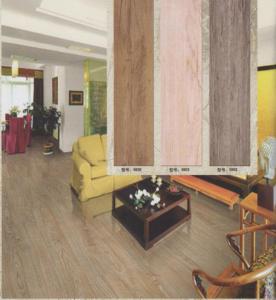

For our wpc decking floor, there are many kinds of types, such as TW-K01(150 x 35 mm)TS-01(150 x 25mm), TH-07(140 x 30 mm), TS-A01(90 x 20mm),TH-16(133 x 24 mm, solid design) etc..

1. Material: 50% natural wood flour; 35%~40%HDPE, 10%~15% additives

2. Color: cedar, grey ,red pine, coffee, brown, nature wood etc.

3. Usage: outdoor, garden, summer house, villa, pool surrounds, exterior floor, seaside walk board etc.

4. Normal length: 5.4 meters/pc, can also be cut according to the requirement of customer.

5. Surface treating methods: Brushing, groove, sanding, embossing etc.

6. CE Approved

7. Advantages:

Keep the excellent character of plastic | Have the properties of wood | Produce fire-new WPC |

weatherproof | easy to cut, fix and glue | Can be recycled with 100% |

no crack, split, warp, or splinter | easy to tenon , drill and nail | No sting of wood |

High dimensional stability | Natural feeling0 | Requires less routine maintenance |

Resistance to insects | Resistance to UV | Is environmentally friendly |

easy to manufacture manifold profiles | innocuous | Multicolor, and needn't to painting |

- Q:Please refer to the ceiling for the floor, or the floor, how does its ownership confirm?

- Both the floor and the ceiling, the separation point is the midpoint of the floor, that is, the upper floor and the lower floor of each half belongs to you.

- Q:I am looking to replace the flooring in my bathrooms

- It depends on what kind of flooring you want to install, and what is already on the floor. If you are going to install a sheet vinyl, and there is more than one layer of existing flooring you will have to remove the old flooring. Then you will probably have to install 1/4 luan or plywood underlay first. Then you will have a nice smooth surface for the new floor. If there is only one layer of existing flooring and it is smooth and tight you should be able to install the new vinyl right over it. Some vinyls have to be glued fully, and then there are others that are only perimeter glue. You should remove the stool, install the new floor, a new seal under the stool and replace it.

- Q:OK. I've been told not to urethane my laminate flooring. How can I seal it to keep water from bath and showers from seeping between the joints and curling? Note: It's pretty cheap laminated panel flooring but it looks nice, now..

- I think all you can do is keep it dry

- Q:Heroes how can we solve the A people always point to the floor of the embarrassment?

- A floor will automatically attack the nearest distance from the enemy

- Q:We are putting in a brand new kitchen and are on a tight budget so plan to use a laminate floating floor. My question is should we put it down before we install cabinets and appliances, or install those first and then put the flooring around them? My husband wants to floor around them to save money, but I think it would look nicer to have the whole floor covered and then put everything on top. What do you think?

- Couple of basic tips will go a long way. Order at least 10% more than the area you intend to floor. Before you start pick a direction to follow, and establish a pattern. You want to make sure you don't waste too much product, but break your seams up so they are not too close together as you proceed across the room. This is not always the longest wall. Keep in mind closets and doorways you will have to work with. Also what is the look you want, how do you want it to flow into other rooms. Undercut door jams before you begin. Pull off all old trim starting at one corner in the room write a number on the back of the trim and on the wall, so you will know which piece goes where. This is not always done, you can install new shoe (1/4 round) over the new floor and against the old trim instead. Remember than no room is square or any wall is straight. The best thing to do is snap a line down the middle of the room then measure over to the wall you want to start at and snap a line about one board width from the wall, but measure from the line you snapped. You may find that you will need to trim a portion of your first board to start with a straight line. Don't forget to leave between 1/4 and 1/2 inch spacing as per manufacturers instructions. Use pieces of scrap against the wood if you need to pound on something, never directly on the piece you are installing. Buy the threshold and termination strips that are made for your flooring product ahead of time. Take your time! Do not rush yourself or the job. It is better to live with your house torn up during the week until the next weekend than to try and rush the job. And of course the old carpenters golden rule - Measure twice - cut once.

- Q:I am considering buying a home Illinois. Unfortunately my price range is small; however there is a home my girlfriend and I love. The floors are slanted because the foundation has sunk because it’s a 100 or more year old home. Is there a way to fix the floors by adding more plywood or something to the lower part of the floor?

- The first thing to do is figure out the amount the floors are off. If there is a place where you can run a string from the front to the back of the house put a nail in the floor wher it is high then run the string to the low end if the height is not to great then you could take 1X3 pine strapping and run it trough 16in apart and shim under to get the height you need at varies points till you get to the high point. Keep in mind that you may have to add to the top of a doorway sadle and cut the door with the process. If the difference is more then 1 to 2 inches then I would have the low end jacked to get closer. It will take a combination if floors are to low on one end. Doing both on really unlevel floors will give you better results.

- Q:there is yellowing on my bathroom floor how can i get this up ? what do i buy it might be from the wetness/ rugs

- What type of material is the floor made of? Does it have a surface protective coating of varnish or polish?

- Q:I need help finding out if the floor in the building I work at is capable of supporting a restaurant.I know an engineer should be hired, but my boss is an architect who thinks he knows.The question comes in two parts-1- 2 1/2" x 12" (actual) joists on 16" centers, 16' 6" long, made of 100+ yr. old western wood (presumably San Francisco area lumber). Are they capable of supporting 100 lbs. sq ft. load?2- If a wall (theoretically non load-bearing, but floor to ceiling, with two floors of apartments above) were put on the floor, parallel to the joist, would the joist underneath it need to be reinforced?If it makes any difference, the floor will be 4" x 4" ceramic tile, on two layers of 3/4" ply.

- No, the floor joist are not adequate. The rule of thumb for residential floor systems is the span of the joist does not exceed the height of the joist. So, a 2x12 maximum span is 12', 2x10 is 10' and so on. Plus, you mentioned added sub floor and ceramic tile - this just adds to the live load on this floor. The supporting wall for the 2 levels above is most certainly going to need the floor joist under it supported. You will have 1 floor joist carrying this added weight of the new wall even if it does not carry much weight from the above 2 floors already in place. Then you add the occupancy load and tables/chairs for a restaurant. Your floor is going to shake every time someone walks across it. What you need to do is go into the basement/or crawls space and install a floor beam perpendicular to the existing floor joist and install it right at the center of the span. Anyway - No, it won't hold the load you have in mind.

- Q:Why do price floors lead to surpluses? What is an example of a price floor?

- An price floor will lead to a surplus because even though the firm would like to lower prices to match the equilibrium price it cannot do so legally. For example, if I am a farmer selling corn that costs 100 dollars to produce the simple market clearing price would be 100 dollars. At a price of 100 dollars the quantity supplied equals the quantity demanded. Now the government hears farms are going out of business. It is in the governments best interest to ensure farms do not close so they put a price floor of 120 dollars into place. Now the farm can sell their corn at a minimum of 120 dollars. Remember the cost to produce the crop = 100. If it is sold at a minimum of 120 then there will be a 20 dollar surplus.

- Q:can you give me some tips so that new vinyl tile floor will adhere to old floor. new vinyl tiles are self stick type

- clean the floor very well use a self leveling thin set and just skim the entire surface making a light coat be sure that it is even and thin let it dry completely use a large drywall taping knife (big putty knife) to spread it after its dry scrape any high spots and sweep it really good then make a chalk line at your center point spread a vinyl adhesive with the big putty knife barely leaving any and let that air dry until it has flashed over then begin to lay your lick and stick tiles pressing them firmly into place when you are done roll the entire floor with a 50 to 75 lbs roller this will set the tile into the pressure sensitive glue and you will have no problems any other way is the wrong way

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hollow decking wpc decking floor outdoor tile wood plastic composite decking wpc

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products