HLS90 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

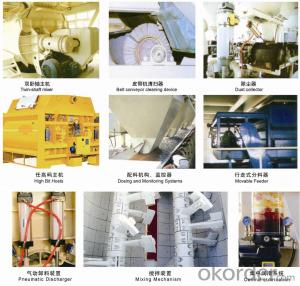

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS90 | |

Production capacity (m3/h) | 90 | |

Concrete mixer | Model | JS1500 |

Power (kW) | 2x30 | |

Output capacity (m3) | 1.5 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | 12 |

Belt conveyor deliverability (t/h) | 450 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 3500±2% |

Cement (kg) | 800±1% | |

Fly ash (kg) | 200±1% | |

Water (kg) | 300±1% | |

Admixture (kg) | 30±1% | |

Discharging height (m) | 3.8 | |

- Q:What kind of technology or machinery is used in the dental office for basic procedures (such as fillings,cleaning, extractions, crowns, bridgework, dentures, etc..)If you're familiar with any of them, please let me knowww....Will give you a Best Answer ...thanks

- Lasers are a real big thing in dental offices, they are minimally invasive, which means they take away the least amount of your natural tooth structure, and they are very precise. you get to keep as much healthy tooth structure as possible and you still get fillings done. we use ultrasonic cleaners to clean your teeth. for crowns and bridgework there is a, new to america and canada, machine called Cerec in office crowns. you get your crowns or bridges in one sitting rather than two, the crown gets madein the office, rather than being sent to a lab, and its made outta material taht is closest to natural tooth structure as possible. also digital x rays deliver 1/8 the amount of radiation compared to traditional x ray machines. check out your local dentist listings for an up to date in technology dental office.

- Q:why are heavy constructions equipments painted in yellow?

- Yellow catches the attention of the eye better than any color on the spectrum, it is a warning of caution...that is why a caution light is yellow but a stop light is red...also why school buses are yellow etc. That correlation between hot colors and caution or stop probably correlates to primitive sense of how colors relate to a threat level...fire is orange...many venomous species are brightly colored...etc. Sorry for the rant

- Q:Okay I went to google and looked up machinery accidents for some odd reason and I came across a pretty gruesome image. I was wondering if anyone could shed some light on it, like who the man was, what type of machine this was and other things.

- Have you tried visiting the site that posted the image?

- Q:Why do many medications caution the consumer not to operate heavy machinery?

- cause many of them make you drowsy,slow down reflexes or may have other adverse side effects.Not a good thing when ya running a machine.

- Q:During 2010 a corporation purchased machinery costing $450,000. This is the only acquisitions of depreciable p?

- Sorry, but your question cuts off in mid-sentence and is hence unanswerable. You'll need to add more info in the 'Additional Details' area of your question screen if you desire an answer.

- Q:Does everyone have like a big strong man using a big strong machine image or something?All I do is pass the broom. I don't have any highschool diploma.

- That's what I thought you did. I figured you didn't have any basic skills to be a machinist and either had to be the guy holding up a shovel every time I drove by or the guy picking up trash in the median.

- Q:Like a Ford 8N tractor, and an old hay rake. The seat is on a hinge, and the farmers (men) always leave the seat up.Do men have some kind of primordial urge to leave seats up? Why did they even make the seats on a hinge? Probably designed by a man.Isn't this the most sexist thing you ever heard?

- That is so if you fall off of it when operating it the seat will spring up and kill the engine. Even my lawnmower has that feature. No one wants to be run over by their own tractor. It has a seat but no engine? How does that work? Maybe it is to keep the seat from getting rained on or baked as others have suggested.

- Q:I need komatsu bucket teeth 6600, middle tooth 480, bucket teeth adapters 140 and tooth point 1000. The price in entity store are expensive, and I will wait for a week at least! Are the products online reliable?

- You can, but why? These type on parts are best if sourced locally, especially for heavy equipment parts, the shipping alone will be a fortune!

- Q:Its for a Geography Flyer on Arable farmingAll info will be gladly received Thank-you

- Machinery to plant, fertilize and harvest crops.

- Q:Suppose that a piston is moving straight up and down and that its position at time t seconds iss = Acos(2πbt)with A and b positive. The value of A is the amplitude of the motion and b is the frequency(the number of times the piston moves up and down each second). What effect does doubling the frequency have on the piston's velocity and jerk?Follow up question, why does machinery break when you run it too fast?

- f = 1/P, where f is the frequency and P is the period P = 2π/(2πb) = 1/b, so P = b Let v = velocity v = ds/dt = -A sin (2πbt) ? 2πb = -2πAb sin (2πbt) Let f* = 2/b, so P* = 2π/(2/b) = bπ v* = -2πAb sin (πbt) The amplitude of the new velocity is 2πb times the original amplitude. Let a = acceleration a = dv/dt = -4π^2Ab^2 cos (2πbt) Let j = jerk j = da/dt = 8π^3Ab^3 sin (2πbt) a* = 8π^3Ab^3 sin (πbt) The amplitude of the new jerk is 8π^3b^3 times the original amplitude. An increased jerk means the machinery is subjected to greater stress, which causes it to break down.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HLS90 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords