HK 293618 RS Drawn Cup Needle Roller Bearings HK Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Specification | Model No.: HK 293618 RS |

Brand Name: OEM | |

Size:29*36*18mm | |

Net weight: 0.025kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

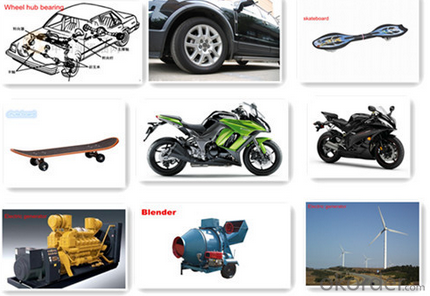

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q:I thought for sure it would be something with the brakes but Pep Boys says it is the wheel bearings that need to be replaced. Which would make some sense because it does shake above 60mph but I didn't think that had anything to do with stopping?

- Warped brake rotors

- Q:I have these skateboard wheels with bearings that have been used for FOREVER, they have probably been in these wheels for more than two years. And this skateboard has been left out in the open all of the time, so the bearings are really really dirty but not too rusted so I am going to try to use them in some different wheels. I have tried to get them out with a screwdriver and using the axel on one of my trucks, but it is so stuck in there with dirt probably that it makes it really difficult to get out, even when I apply a lot of pressure. I don't think it is physically possible for me to get it out with just human force, or maybe it's just me, idk, I have tried and tried and I've already broken one nail trying to get these stupid bearings out and I just want an easier way. What other things can I try to get them out of the wheels? I think they are still usable, probably they just need cleaning.

- Removing Skateboard Bearings

- Q:can you use these bearing interchangable?

- N design Inside track with two unitary flanges, while outside track without flange. Axes's axial displacement to bearing block can be endured by bearing from two directions. Therefore, these bearings usually used as non position end bearings. NU design The outside track of NU design bearings has two unitary flanges, while inside track without flange. Axis's axial displacement to bearing block can be duded by bearing from two directions. Therefore, these bearings usually used as non position end bearings. Due to the reason of manufacture and maintenance, two flanges of outside track of NU design big bearings showed on drawing maybe not unitary, but with loose fit-up flange rings. NJ design Outside track has two unitary flanges, inside track also with one unitary flange. Therefore, these bearings suitable for the axial orientation of axes from one direction. Since their design and usage are for different purposes I would say no they are not interchangeable.

- Q:I have a 2001 Nissan Maxima Se, when i jack tha car up (on the driver side) my wheel is loose, obvisouly with the lug nuts screwed all tha way in, i talked to a few people, but they sed it could be my Wheel Hub or my bearings, i don't know, i just don't wanna get robed blind, wat would be a reasonable amount of money + labor to fix either tha hubs or tha bearings on tha one side???

- Front or rear? The rear has hubs that are sealed for life now (except for RWD, AWD and 4WD). They do go out. On FWD (and 4WD) the front has bearings, and these also go bad. They are also sealed for life bearings, but these are serviced by pressing the old bearings out and pressing new ones in. There is the off chance that it is a loose nut on the axle by the way. Or a bad ball joint. But I am assuming that you know that it is the wheel moving and not the whole rear member.

- Q:i have rush abec 3 bearings, and i cant DROP IN on the mini ramp, i have to push in the middle because if i drop in my board will go over the coping, im wondering what bearings are good to go fast enough but slow enough to where i can control it when i drop in

- ???

- Q:http://www.amazon .uk/Bones-Reds-Skateboard-Bearings-Red/dp/B000FDRQ1S/ref=sr_1_1?ie=UTF8qid=1377987075sr=8-1keywords=bones+redsAnd tell me if the price is good for their quality.

- These bearings are amazing for skateboarding. I bought a pack and I love them. They are well built and durable bearings for a fantastic price. I would buy them for sure.

- Q:im a begginer in skateboarding so i wanted to know if abec 5 bearings were good bearings and if not wich ones should i get tahnk u!!!

- Abec 5's are a good happy medium

- Q:Building a longboard

- Bearings are the same unless you have 10mm axles. You would know this when you get the trucks. They use a different bearing, but the wheels are the same. Skateboard parts are standardized.

- Q:I'm in alot of downhill skating events but no wins. What bearings could i use that are the fastest in ur opinion and name them all i use are redz bonez.

- dont do what steve says! wd 40 leaves residue and makes them even worse in a couple of weeks

- Q:It has a clunk in the front left wheel when driving and when sitting naturally (not jacked up) i can pull on the top of the wheel and it has a loose feel to it and the lug nuts are tight. so i was wondering if it has the wheel bearing that would need to be changed or like a axle bearing needing changed. the difference being that i think you would have to pull the axle to change an axle bearing and the wheel bearing you would need only to pull the tire and rotor. Keep in mind it is a 4wd. thanks.

- Sounds like a ball joint.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HK 293618 RS Drawn Cup Needle Roller Bearings HK Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products