HK 1716 Drawn Cup Needle Roller Bearings HK Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Specification | Model No.: HK 1716 |

Brand Name: OEM | |

Size:17*23*16mm | |

Net weight: 0.016kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

HK Seal/close type Drawn cup needle roller bearings HK :

1. High accuracy, High speed

2. ISO 9001:2000

3. Can be customized according to your needs

4. Can provide small & miniature standard and non-standard ball berings

5. Reasonable price

6. Technology: low vibration, low noise, high precision and durability

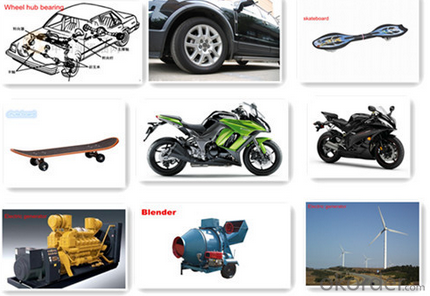

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q:I have these skateboard wheels with bearings that have been used for FOREVER, they have probably been in these wheels for more than two years. And this skateboard has been left out in the open all of the time, so the bearings are really really dirty but not too rusted so I am going to try to use them in some different wheels. I have tried to get them out with a screwdriver and using the axel on one of my trucks, but it is so stuck in there with dirt probably that it makes it really difficult to get out, even when I apply a lot of pressure. I don't think it is physically possible for me to get it out with just human force, or maybe it's just me, idk, I have tried and tried and I've already broken one nail trying to get these stupid bearings out and I just want an easier way. What other things can I try to get them out of the wheels? I think they are still usable, probably they just need cleaning.

- If you are going to wash the bearings properally then try putting the wheel and bearing in boiling water to soften the wheel, then get a bolt with a head that fits over the bearing but inside the wheel and hit it with a hammer, WD-40 helps to loosten them too, ideally you would need a press.....but i dun think you've got that. when pressing the bearing try to put the pressure on the innner race (the inner circle bit) as not to warp them. if they have been out in the weather for too long they might be buggered, soak them in some petrol for a while, and exercise them (spin them round) a bit, blow some air through them if you can, then oil them up with a really thin oil, there is also other stuff you can use to clean them, there might even be proper cleaning solutions, but petrol works well, or even turps. wear some gloves but, cos it can sting ya hands and it's not good for you.Just persist with the bearing mate, try not to twist it side to side in the wheel, cos that could get it stuck. Hope that helps.

- Q:and what are they used for?

- there iside the wheel thats what lets it roll

- Q:I have reds bones bearings and they were all fine until today. I got them over a month ago and haven't cleaned them. Today I ran over a pebble going fast and fell. Right after that my bearings on one of my wheels stopped spinning. I could ride but they don't spin when I spin them with my hand. I think something got in the bearings. It's both of the bearings in the wheel not just one. What could I do to check if there's anything in them? What do I do if there is? And how do I clean the bearings? What do I need? Thanks for helping!

- Take your bearings out and clean them

- Q:what year did they come out with them? i know swiss came out in 83

- Bones Swiss bearings came out in 88. There were other Swiss bearings on the market, though. Reds are much newer, coming to market in the early 2000s

- Q:from fast forward?

- well there's no such thing as a pro skateboard...but what do you mean by what kind of bearings...brand or abec? if you're talking about abec then most pro street skaters use abec-5 bearings, while vert skaters like a bit more speed. so theyll use abec-7. abec-3,5, and 7 are the most common. the higher the number the faster and longer the bearing will make the wheel spin, but they need cleaned often and dont last as long. as for the brand, they will skate bearings from whichever company gives them sponsorship. most pros do not skate element bearings, they skate whoever they're sponsored by.

- Q:i wannn know to see if its a good idea to try :)

- Yes...by washing away the very grease that lubricates and protects them...So does gasoline make bearings run faster?..Yes....Makes them wear out much faster also!

- Q:how can loose fits cause failure in bearings? and in particular affect the outer diameter?i am seeing a failure catalog for bearings, and i read : discolartion and scoring is the result of the outer ring slipping in the housing. why outer ring?

- Bearings are matched to shafts and housings to a tolerance of .01mm (ideally). This fit permits creep to distribute wear over time, while providing uniform and stable support for the inner and outer races. Tighter (interference) fits are destructive. Loose fits, which permit chatter and impact, are equally destructive. If you are involved in maintenance you will get your money's worth from the attached link.

- Q:This is a mid-1970's Schwinn. Obviously, if there is grit or dirt or rust I will clean them. My instinct is to use 3 in 1 oil if I must, then repack everything in good old reliable bicycle grease. But if there is just old grease without anything gritty, do I even need to clean the bearings etc., and if so, what cleaning agent do I use?

- To clean bearings of grease you want to use a solvent. Several are available. Find one of these; mineral spirits, kerosene, or brake wash (aerosol). Use a parts cleaning brush and don't drop a bearing. Once they hit the floor they run and hide. Hard little critters to find, too. I use a magnet to pull the bearings out unless the old grease is too thick. The balls themselves can be put in a jar or tin with the solvent and soaked. Clean the race with the brush. I use an old metal coffee can to place the hub over and dip the brush in the can. It runs back inside to contain the mess. If you have compressed air you can blow them dry. If not you can force a piece of clean rag through the hub to dry. Inspect the clean race for pitting. (If there is pitting the race needs replaced and in most instances that will require a new hub.) Press the new grease in the race with your finger and place the balls one by one into the grease pressing them in. The new grease will hold the bearings from falling out. Don't worry if you think you are using too much grease, the excess will ooze out as you install the axle and you can wipe it off. Don't over tighten the axle nuts. There is a fine touch between play and over tight. With new grease I tighten them them to space the balls properly, then back off and tighten them for the proper feel.

- Q:I have a 1992 Camaro RS, LO3 305 TBI V8, Automatic, 125k miles. It had the oil changed awhile ago, not sure what they put in it, but when I picked it up, the engine was ticking (sounded like a lifter or failing oil pump). I've driven it a few thousand miles and it runs good and strong, but I've always noticed that the oil pressure guage reads low, between 5-25 psi. I'm concerned my bearings are shot. It normally starts up at 25psi and after driving 10-20 minutes, it reads 5-10 psi, and the ticking becomes slower. The engine never kills though. Could it just be a case of a bad sending unit, with to light of a weight of oil, or bad bearings? What are some common signs of bad bearing? The motor does not knock.

- if your bearings are bad your engine would be knocking and would soon stop. it sounds like your bearings are worn which would give you low oil pressure. I would run the oil made for older engines that have wear like yours.and by the way try not to beat it to much it'll last a little longer

- Q:I have split the case, and removed the crankshaft and bearing seals. I want to replace the the crank Bearings. What is the best way to to get them out with out damaging the case? Also, when it is time to install the new crank do I need to use the Yamaha Installing pot tool? I can't find this tool anywhere.

- Yamaha Blaster Crankshaft

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HK 1716 Drawn Cup Needle Roller Bearings HK Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords