HJD Type Chemical Multi-stage Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

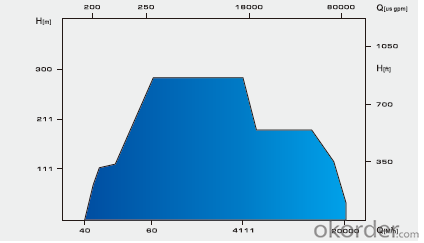

HJD is a centrifugal pump of horizontal, single suction, multistage, and radial split structure.

Conform to ISO9005, GB/T16907, API682 standard.

Head: 100~1100m

Capacity: 3~800mr/h

Temperature:-80~180oC

Max operating pressure: 15Mpa

2. Application

It is used to convey clean medium without particles or corrosive/non-corrosive medium with suspended substance.

Industrial water supply

Power plan(thermal power, nulcear power)

Petrochemical industry

Cooling or hearing system

City water supply

3. Material

For wetted parts in contact with medium, the common materials are as following,

304, 321, 316L, 0Cr25Ni6, TA2

4. Pump Structure

5. FAQ

1 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

2 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

3 Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

- Q:We have a 92 cadillac deville, my husband can replace the water pump he justs need to know if you have to jack the motor a little. Please help before our car blows up!!

- Make a run to your nearest AutoZone pick up a repair manual. THey're maybe $15-20, but pretty useful.

- Q:Can I charge the battery (1.2Vx2) with the suction tube submerged in the water or do I have to remove the suction tube every time I have to charge the battery?

- Since you don't mention the model of the pump, if you can connect the charger with a dry connection, you should not have to remove the pump/tube. If you have to take the battery out, you stand the risk of dropping it in the water putting it back, but obviously (I think) you don't have to remove the pump/tube.

- Q:My boyfriend told me that my car needs a new water pump. He said this because when you start the car, it sounds like trickling water is coming from somewhere in the engine bay. The car overheated once before and he put coolant in it, ever since then, it hasn't overheated. But last week he told me that I shouldn't drive it at all because the pump is about to go. I went out today and started it to see if I can hear the quot;grindingnoise that I read about online and all I hear was the trickling sound. It's rainy outside so I can't tell if the pump is leaking water from the quot;weepquot;. Is it the water pump? I want to make a two mile round trip to go pick up sushi and the place is a mile there and a mile back. Will I seize my engine or get stranded if I make this tiny trip? Is it my water pump?

- Nicky, There are usually only two reasons to change a water pump and it's easy to check both of them. #1. With the car on ramps or jack-stands crawl underneath and look at the water-pump weep hole on the bottom of the input shaft casting. If coolant is leaking out the hole the pump needs replacing. Coolant will leave a perfect track from the weep hole the same color as the antifreeze. #2. Remove the serpentine belt and spin the water-pump by hand. If it spins with no noise or a lumpy bearing feeling in your fingers the water-pump is fine! While the belt is off, spin all the accessory pulleys to hear and feel if there are any bad bearings.

- Q:Question for you. I'm looking for a 12v (no AC converter, please) water pump to drive up to 4 water misters. Needs to run off the battery, without an AC converter (already found those). The pump will pull from a water reservoir and provide cooling relief on hot days through the misters. BTW... the pump should be reasonably small, limited to a few pounds...If you have any ideas, please advise.Thanks again,Robert

- Again, I'm going to make you work for this one. Call around to junk yards. See if they have any parts you can use. There's a bunch of Pull Apart places where you can look up online to see if they have any particular part you're looking for. I don't know how much a typical automobile water pump weighs, but I don't imagine it would be too big. Ask around. If you know any mechanics, or just people who work on cars as a hobby, they may know. Sorry I'm not much help in the automotive department. I can put gas in it, start it, change my oil, and change a tire. But as far as the rest goes, I don't know too much.

- Q:A pump parameter is the maximum flow per hour 960L, followed by the standard flow of 480 what do you mean?

- The parameter standard of the pump factory is determined by its efficiency, that is, the efficiency of the pump is highest at that point. All parameters have two curves, that is, a flow curve and an efficiency curve. You can according to your standard flow, see how much the efficiency of the point, the maximum flow efficiency is how much will know.

- Q:Hi there: my water pump is leaking, and my coolant lelel keeps droping, same problem. Im not sure if coolant flows through the water pump?

- yes water goes through the water pump and if it's leaking you need to replace it.

- Q:i have a 2003 dodge neon and my thermostat keeps rising to the highes level setting off the indicator (its not broken) i did have a leak in the raiditor and it was very notice able..after pacthing is up there was noproblem till yesterday now the thermostat keeps rising i admit the is very little antifreeze in ther and the rest is water but the is the same mixture tha was in the care that it was rinning off for the last three minths i cannot seem to keep the thermostat down my raiditor is in nee of repair but i m wondering if its the water pump does the water pum help regulate engine temperture? ther are no ivsible leaks and no drippiage could it be that i just need to put antifreeze or could it be the water pump or a broken raidiator? help i will give points for best anwser but really i just need help!

- Could be the water pump. That's what moves the antifreeze around to cool your engine. It could also be the thermostat, or even its fuse. Check thermostat fuse. There's no way to know from your description, there are many reasons for overheating. Best have the codes pulled and see what the car tells you is wrong with it.

- Q:I have a 2000 chevy impala with 85K on it. I have heard/a weird rattle noise from under the hood for some time now. I once asked about it on here and got suggestions regarding front end problems. I had that checked out and the front end is good. I still have the rattle noise along with a high pitched, but not very loud, squeeling noise when I accelerate. I am leaking coolant and it seems to be coming from near one of the belts. Is this a bad water pump? If so how expensive of a fix is it and how involved of a repair is it?

- It sounds like a water pump or maybe a loose connection. It is probably time for a water pump if it hasn't been replaced yet. Parts will run under $60 and it probably involves an hour of labor. The Impala is a big car, it shouldn't be hard to get to and remove. Taking it to a shop will run under $100-$150 for everything.

- Q:I received a call from my daughter who said that the water pump was making a grinding noise. She sent a photo to me showing 0 psi on the gauge. I came home to find it actually working again but after running water straight from the pump I found that it is really rusty. What is this caused from? Our water was nice and clear! We've had freezing conditions here. Still doesn't explain the sudden rust.

- Ok there are several possibilities one is that since pressure went to zero you stirred up sediment in the surge tank especially if it is the old style before bladder type also if air got into pipes that will loosen rust but these are minor and will clear with time and use but i would worry what is wrong with pump that goes to zero and makes noise you better check that out or your at risk it wont restart next time

- Q:i have an 80' water well with an electric jet pump. is there an electric/manual water pump? i want to be able to have a hand pump attached to the electric pump, so i can still use water when the electricity goes out.

- Yes but you need a hydrological manual secretor to recreate the same power as with electricity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HJD Type Chemical Multi-stage Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords