Highly purity ceramic fiber anti-Heat board STD22

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Highly purity ceramic fiber anti-Heat board STD

High purity ceramic fiber board

General information of ceramic fiber board

Cmax ceramic fiber board is made of high quality kaolin clay, centrifugal high purity alumina and silica or blowing process. It's no asbestos. Double side acupuncture for the board, with a lot of tensile strength or strong, easy to install.

Products are divided into standard, high pressure, HA and Hz, respectively, corresponding to the highest service temperature of 1000, 1100, 1200, and 1350

Characteristics of ceramic fiber board

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Thermal shock toughness

High tensile strength

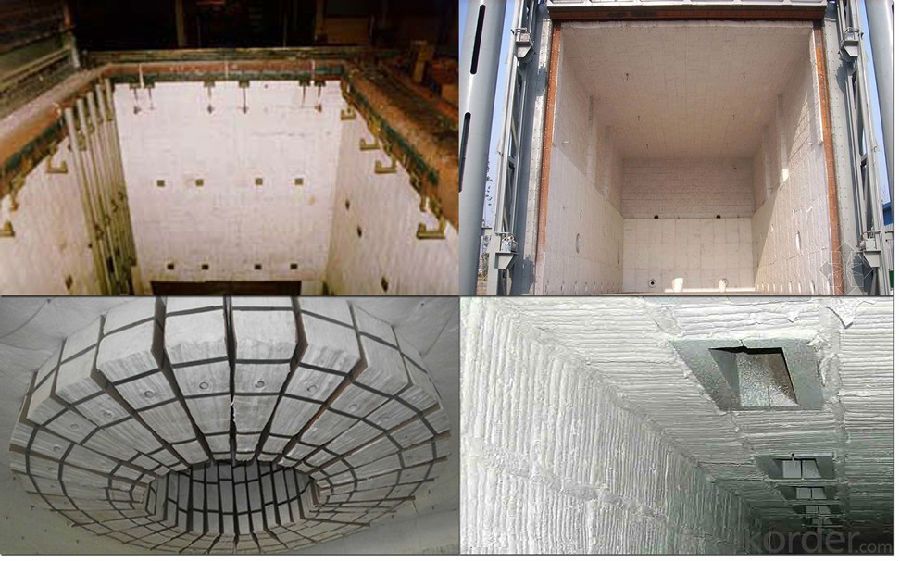

Application of ceramic fiber board

Refractory fiber lining for petrochemical process heating furnace

Heat treatment furnace or intermittent (shuttle) kiln heat surface lining

General oven standby insulation

Heat sealing or kiln kiln car door

Electrical insulation

Ceramic fiber board

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

- Q:I currently own a small gift shop in my hometown and was wanting to start carrying the baby headbands that are so popular right now but can't find what they use to make themIt is called crochet elastic but I have looked in all of the craft stores in my area and haven't found anyDoesn't anyone know a website I could order it fromWholesale or not I don't care, I just really want to find the stuff.Thank you so much!

- Definitely!! But, the easiest way I have found is to Micro them first depending on the size approx3 minthen place in the oven or toaster oven, and use olive oil (I use garlic ooil) on the skin rub it on put it in the Toven 300, regular oven 350(like I said depending on the size) until you can pierce with a small sharp knife on the top of the potato, take it out let it set on a cookie rack for 5 to 8 minutes, where you knifed it, do the same thing the entire way across and squash itit will fluff upReally it will You can either scoop it out for twice baked potatoes add what you choose or use as a regular baked potato GREAT

- Q:-Explain Ohm's Law and give several mathematical examples.26Calculate the current where 10 coulombs of charge pass a point in 5 seconds.27Calculate the current of a lightning bolt that delivers a charge of 35 coulombs to the ground in a time of 1/1000 second.28Calculate the current in a toaster that has a heating element of 14 ohms when connected to a 120-V outlet.29.Calculate the current in the coiled heating element of a 240-V stoveThe resistance of the element is 60 ohms at its operating temperature.30Electric socks, popular in cold weather, have a 90-ohm heating element that is powered by a 9-volt batteryHow much current warms your feet?31How much current moves through the fingers (resistance: 1200 ohms) if you touch them to the terminals of a 6-volt battery?32Calculate the resistance of a filament in a light-bulb that carries 0.4A when 3.0 V is impressed across it.33Calculate the current in a 140-W electric blanket connected to a 120-V outlet.

- There are three basic mechanisms for heat transfer: conduction, convection, and radiationAir is a worse thermal conductor than styrofoam, but convection dominates if it is allowed to flow (hot air rises, for example)Porous solids such as stryofoam are more effective than air alone because they entrain the air, preventing convective heat transfer.

- Q:These are the instructions that came with my new swimsuitIt got me to thinking that when I use a translator, I must sound horrible, lol.Use and maintenance1、into the water before swimming and bathing suit full wet pants2、Avoid wearing rough rock or ground with friction, to prevent the fibers take the yarn3、Wet swimming suits and can not be placed in a plastic bag by a long sea or pool water immersion, easy tocolor.4、Hand wash with water as soon as possible after swimming, do not use detergent and bleach5、Washed in ventilated place to dry, do not direct exposure to sunlight is.6、Stored for long periods, do not place the product in a concentrated taste of the cabinet mothSo, why can't they make a translator that actually works?

- The Ultimate her straightners cost big bucks were not talking about is going to be more than 80 dollars I would not pay 300.00 for GHD Even if name brand, I would say this would have to work like GOLD ON MY HAIR for price I personally don't see what so espeically other than a lot of girls bragging about itI can't say for my self because I own other brand of flat iron) moving on I seen a few of older name brands like Cortex, Inonkia Professional, Corliss, ISO Turbo Silk (I own that one) Babyliss a few other for about 29.99 to 40 dollars So you might want to check TJ Max first

- Q:Considering the thermal conduction of Co2 is so low, and the price is also ridiculously low, why arent gas filled bladders with co2 used in insulation of say, greenhouses in very cold places? Does it leak out? Do the bladders pop too easy? Have people just not thought of this?

- No, you can get free estimates from most placesI do not know where you live, but we had one cut down in the 1970s and it cost us $700.00, then they did not haul off the wood, and we gave it away to people who could use it thenNo one burns fireplaces as much now as they used to doMake sure you get a licensed contractor to do itWe had someone trim a tree that was not on our property, and they mashed the neighbor's fence, but it was their treeHe was not licensed and did not repair the fence, but they had him do some trees in the back, and those were the ones that fell on itLook on Angie's List if you want to find someone reliable.

- Q:Does fiber really reduce risk for colon cancer? Some studies say it does, others say it doesntWhich is true?

- DietStudies show that a diet high in red meat[2] and low in fresh fruit, vegetables, poultry and fish increases the risk of colorectal cancerIn June 2005, a study by the European Prospective Investigation into Cancer and Nutrition suggested that diets high in red and processed meat, as well as those low in fiber, are associated with an increased risk of colorectal cancerIndividuals who frequently ate fish showed a decreased risk.[2] However, other studies have cast doubt on the claim that diets high in fiber decrease the risk of colorectal cancer; rather, low-fiber diet was associated with other risk factors, leading to confounding.[3] The nature of the relationship between dietary fiber and risk of colorectal cancer remains controversial.

- Q:its a fibre giving animal

- I prefer Berber carpet

- Q:I got a quote of $411 to add R38 blown in fiberglass 12.75quot; thick over my 3-car garage which is uninsulatedWould it make more sense to add a whole house attic fan instead? My thinking is that adding the insulation to the garage will do nothing to keep the entire house cool, whereas the fan will help not only keep the garage cooler, but also the whole houseI have a quote of $580 for the attic fanSo for $169 more, I could have the fan installed and just skip the insulationPlus the local energy company rebates $50 for an attic fanup to $125 if it's solar poweredIf you have experience with this type of thing, I'd appreciate your thoughtsThank you.

- the attic fan will not do much good if you turn on the cool A/C - probably best to put roof vents and whirleybirds to take the heat/hot air out of your attic -

- Q:cause like everytime i straighten it goes all frizzyi use a ceramic straightener and chi thermal protection spray.but whats a perm and what does it do and how does it look like?if you can please put a link to a picture of a perm.please and thank you.

- There are two main types of permsCHemically straightening: This makes the hair straight however it cant make the hair dead straight it just makes the disulphide bonds inside the hair and reforms them in a straight line :) Its very damaging and can go wrong Perms: This is a different process, the hair stylist wraps hair round rollers and uses the same solution from a chemical straightener, and breaks the bond and then reforms them to the shape of the curler making your hair curly Both are perminant to the hair thats been affected but when your roots grow trhough they are like your natural hair so you need to keep getting it done There are lots of risks with perms, if you leave it on too long then your hair can break and become chemically burned, if you dont leave it on long enough then your hair wont take itIts best just to get some new straighteners, yours might just have too much static :) Other than that theres not alot you can do!

- Q:I have a hot water boiler to heat my old houseI have insulated the pipes in the crawl space and only the roof in insulated (not walls or the crawl space) its around 15F right now, i have my heater at 60F because i honestly cant afford to keep it any higher, plus my girlfriend loves it cold when shes asleep (canadian)Sense some of boiler pipes are next to the reghot and cold pipes (by next to i mean a few feet away) will the boiler pipes keep the pipes warm unuff to prevent freezing in the crawl space? Basically do my pipes run a risk of freezing at this moment? An how good does pipe insulation really work? I insulated with 3/4in an on the corners i sprayed foam insulationThanks in advance!

- You say the youngsters' litter box is small with small edgesHave you tried using a cake pan size litter box ( or even use a cake pan )? These are only 2 tall, so a kitten doesn't have to climb in.Maybe, that would work better for that one who doesn't like to climb? Climbing onto a sofa is NOT the same as trying to get over the lip of a boxThe kittens use their claws to climb on furnitureOnce the kittens get a little bigger, you can go back to the box you're using nowAs for the carpet, you can get a plastic place mat and set it in front of the box.or a few so that you can cover all sides.much easier to wipe off than clean the carpet! Hope this helps.Good luck.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Highly purity ceramic fiber anti-Heat board STD22

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords