Higher Finishing Surface CRC Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

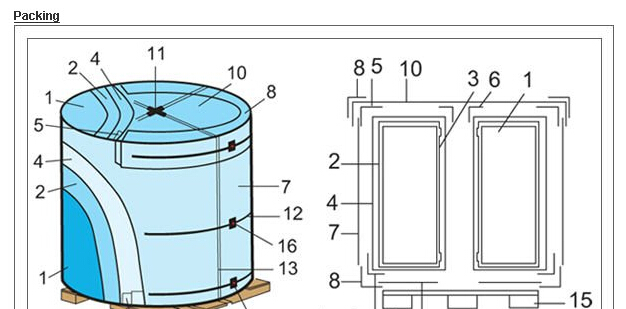

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508&610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

DC01 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

DC03 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

DC04 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q:How is steel used in the production of industrial machinery?

- Steel is used in the production of industrial machinery due to its exceptional strength, durability, and versatility. It is used to construct the framework and components of machines, providing them with the necessary stability and resistance to withstand heavy loads and harsh operating conditions. Moreover, steel's malleability allows for easy fabrication and shaping of intricate parts, enabling the production of complex machinery. Additionally, steel's resistance to corrosion ensures the longevity of industrial machinery, making it a reliable material choice for manufacturers.

- Q:How is steel used in the manufacturing of household appliances?

- Steel is commonly used in the manufacturing of household appliances due to its durability, strength, and resistance to corrosion. It is used to construct the framework and outer casing of appliances such as refrigerators, ovens, washing machines, and dishwashers. Additionally, steel is also used in the production of various internal components and mechanisms, ensuring the overall reliability and longevity of household appliances.

- Q:What are the different types of steel profiles used in conveyor systems?

- There are several different types of steel profiles used in conveyor systems, including C-channels, I-beams, angle bars, and square or rectangular tubing. These profiles are chosen based on the specific requirements of the conveyor system, such as load capacity, structural integrity, and ease of installation.

- Q:How is steel produced?

- Steel is produced through a process called steelmaking, which typically involves the combination of iron ore, coal, and limestone in a blast furnace. The iron ore is first mined and then refined into iron through a series of heating and cooling processes. The refined iron is then combined with coal and limestone in the blast furnace, where it is heated to extreme temperatures to remove impurities and convert it into molten iron. This molten iron is then further processed to remove any remaining impurities and adjust its carbon content to create different grades of steel.

- Q:How is steel used in the manufacturing of water treatment systems?

- Steel is commonly used in the manufacturing of water treatment systems due to its durability, strength, and resistance to corrosion. It is often used to construct tanks, pipes, and other components that come into contact with water, ensuring the system's longevity and reliability.

- Q:How are steel products used in the mining industry?

- Steel products are widely used in the mining industry for various purposes such as infrastructure construction, equipment manufacturing, and ore processing. Steel is used to build strong and durable structures like mine shafts, tunnels, and support systems. It is also used to manufacture mining equipment such as drills, crushers, and conveyors, which are essential for extracting and transporting minerals. Moreover, steel is utilized in the processing of ores through grinding mills and smelting furnaces. Overall, steel products play a vital role in enhancing the efficiency, safety, and productivity of mining operations.

- Q:What are the factors to consider when choosing the right steel product for a specific application?

- When choosing the right steel product for a specific application, several factors need to be considered. First, the mechanical properties of the steel, such as its strength, hardness, and ductility, must align with the requirements of the application. Additionally, the corrosion resistance of the steel is crucial, especially if the product will be exposed to harsh environments. It is also important to consider the desired formability and weldability of the steel, as well as its cost and availability. Lastly, specific industry standards and regulations should be taken into account to ensure compliance and safety.

- Q:How do steel products contribute to the transportation and logistics sector?

- Steel products play a significant role in the transportation and logistics sector by providing strength, durability, and versatility. Steel is commonly used in the construction of vehicles, such as cars, trucks, trains, ships, and airplanes, due to its high tensile strength and impact resistance. It ensures the safety and reliability of these vehicles, enabling them to carry heavier loads and withstand harsh environmental conditions. Additionally, steel is used in the infrastructure of transportation systems, including bridges, railways, and ports, ensuring their stability and longevity. Overall, steel products are essential for enhancing the efficiency, safety, and sustainability of the transportation and logistics sector.

- Q:How is steel wire used in the manufacturing of springs?

- Steel wire is commonly used in the manufacturing of springs due to its high tensile strength and flexibility. It is typically coiled or bent into the desired shape, allowing it to store and release energy when pressure is applied. The steel wire's resilience and durability make it an ideal material for creating springs that are used in various applications, such as automotive suspensions, mattresses, and mechanical devices.

- Q:Can steel be recycled?

- Yes, steel can be recycled.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Higher Finishing Surface CRC Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords