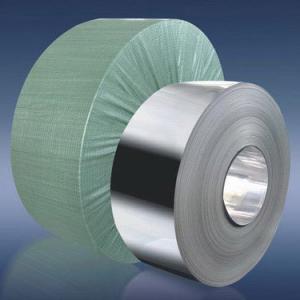

Higher Finishing Surface CRC Coil 0.4-2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

St12 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

St13 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

St14 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness<0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q:How is steel used in the manufacturing of railway tracks?

- Steel is used in the manufacturing of railway tracks due to its strength, durability, and ability to withstand heavy loads. It is mainly used to create the rails which form the track structure, providing a smooth and stable surface for trains to travel on. Additionally, steel is also used for various components like sleepers, fasteners, and ballast that help support and maintain the integrity of the tracks.

- Q:How do steel products contribute to the construction of hospitals and healthcare facilities?

- Steel products contribute to the construction of hospitals and healthcare facilities in various ways. Firstly, steel is used in the structural framework of these buildings, providing strength and stability. It allows for the construction of large open spaces, which are essential for accommodating medical equipment and facilitating smooth patient flow. Additionally, steel is used in the manufacturing of doors, windows, and other fixtures, ensuring durability and security. Moreover, steel's fire resistance properties make it an ideal choice for critical areas like operating rooms and laboratories. Overall, steel products play a vital role in creating safe, reliable, and functional healthcare environments.

- Q:How are steel gratings used in industrial flooring?

- Steel gratings are commonly used in industrial flooring as they provide a strong and durable surface for workers to walk on. They are designed with an open grid pattern that allows for efficient drainage of liquids and debris, making them ideal for environments where spills or moisture are common. Additionally, steel gratings offer excellent traction and can withstand heavy loads, making them suitable for areas with heavy machinery or equipment. Overall, steel gratings enhance safety and efficiency in industrial settings by providing a reliable and slip-resistant flooring solution.

- Q:What are the applications of steel in the petrochemical industry?

- Steel is widely used in the petrochemical industry due to its excellent mechanical properties, corrosion resistance, and high strength-to-weight ratio. It is utilized in the construction of storage tanks, piping systems, and process equipment such as heat exchangers and reactors. Additionally, steel is employed in the fabrication of offshore platforms, refineries, and petrochemical plants, providing structural support and ensuring the integrity and safety of these facilities.

- Q:What are the applications of alloy steel in manufacturing?

- Alloy steel is widely used in manufacturing due to its exceptional properties. It is commonly used in applications that require high strength, resistance to corrosion, and heat resistance. Some specific applications include automotive parts, aircraft components, construction equipment, and machinery parts. Additionally, alloy steel is used in the production of tools, such as drills, cutting tools, and dies, as well as in the manufacturing of gears, shafts, and bearings.

- Q:How does steel tube bending work?

- Steel tube bending works by using specialized machinery and techniques to apply force on a steel tube, causing it to bend into a desired shape or angle. The tube is typically secured in place and a bending tool or die is used to exert pressure on the tube, gradually forming it into the desired curve. The amount of force applied and the tool's shape determine the degree and radius of the bend. This process is commonly used in various industries to create custom-shaped steel tubes for a wide range of applications.

- Q:How is steel used in the production of process equipment for chemical plants?

- Steel is commonly used in the production of process equipment for chemical plants due to its high strength, durability, and resistance to corrosion. It is used to fabricate various components such as tanks, reactors, pipes, and valves, ensuring they can withstand harsh chemical environments and high-pressure conditions. Additionally, steel can be easily welded and shaped, allowing for custom designs and efficient manufacturing processes in the production of process equipment for chemical plants.

- Q:How do steel products contribute to the electrical and power transmission sector?

- Steel products play a crucial role in the electrical and power transmission sector due to their high strength, durability, and conductivity. Steel is commonly used in power transmission towers, which support overhead power lines and ensure efficient distribution of electricity. Additionally, steel is utilized in electrical transformers, switchgear, and circuit breakers, where its magnetic properties facilitate efficient energy transfer and control. Overall, steel products provide the necessary infrastructure and components for reliable and safe electricity transmission, making them indispensable to the electrical and power transmission sector.

- Q:How is steel wire rope used in elevators?

- Steel wire rope is used in elevators to provide the necessary strength and durability to support the weight of the elevator car and passengers. It is used as the primary load-bearing component, connecting the elevator car to the counterweight system and the hoisting machinery. This wire rope is designed to withstand high tensile forces and is crucial for ensuring safe and reliable vertical transportation in elevators.

- Q:What are the common uses of steel in the mining industry?

- Steel is commonly used in the mining industry for various purposes such as construction of mining equipment, infrastructure, and vehicles. It is also used in the production of drill bits, conveyor belts, and crushers. Additionally, steel is essential for creating support structures, including mine shafts and tunnels, due to its strength and durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Higher Finishing Surface CRC Coil 0.4-2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords