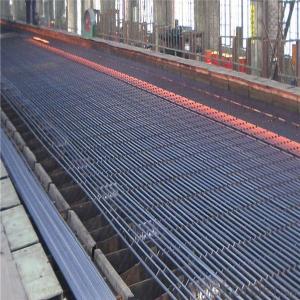

High Tensile Deformed Steel Rebar Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Most grades of steel used in rebar cannot accept welding; such as, to adjacent steel plates or as means to bind

single pieces of rebar together. However, special grades of rebar steel and welding rods make welding by expert

welders possible.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or

covered with special plastic "mushroom" caps.

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:What is the purpose of ribbing on a steel rebar?

- The purpose of ribbing on a steel rebar is to enhance the bond between the rebar and the surrounding concrete. The ribs, which are raised deformations along the length of the rebar, create a larger surface area for the concrete to grip onto. This increased surface area improves the mechanical interlock between the rebar and concrete, resulting in better load transfer and enhanced structural integrity. The ribbing also helps to prevent slippage or movement of the rebar within the concrete, ensuring that the reinforcement remains in its intended position, even under heavy loads or seismic activity. Overall, the ribbing on a steel rebar plays a crucial role in improving the performance and durability of reinforced concrete structures.

- Q:What is the impact of steel rebars on the construction timeline?

- The construction timeline is greatly affected by steel rebars. These rebars are essential in reinforced concrete structures and provide strength and durability to the overall construction. It is crucial to properly install and integrate them into the concrete elements to ensure the building's structural integrity. To begin with, delays in procuring or delivering steel rebars can have a significant impact on the construction timeline. This can cause a ripple effect, postponing or slowing down construction activities that require the presence of rebars, such as formwork, concrete pouring, and curing. As a result, the overall construction timeline may be delayed. Furthermore, the installation of rebars is a meticulous and time-consuming process. Construction teams must accurately place and secure the rebars according to design specifications and engineering drawings. This involves cutting, bending, and tying rebars to create the necessary reinforced structures. Any errors or rework needed during this phase can lead to additional time being spent, potentially causing delays in subsequent construction activities. In addition, coordination between different construction trades is crucial when working with rebars. The integration of electrical and plumbing systems with rebars must be done correctly before pouring the concrete. Miscommunication or lack of coordination can result in conflicts and rework, causing delays in the construction timeline. Moreover, the quality of rebars is vital to the construction timeline. Poor quality or defective rebars can pose safety concerns and potential structural issues. In such cases, remedial actions, such as removing and replacing faulty rebars, need to be taken, leading to delays and additional costs. In conclusion, steel rebars significantly impact the construction timeline. Factors such as availability, timely delivery, accurate installation, coordination with other trades, and quality influence the overall progress of a construction project. Proper planning, communication, and monitoring are essential to effectively incorporate rebars into the construction process, minimizing potential delays, and keeping the project on schedule.

- Q:Can steel rebars be replaced with other reinforcement materials?

- Yes, steel rebars can be replaced with other reinforcement materials. While steel rebars have been widely used in construction for their strength and durability, alternative materials have been developed that offer similar or even improved properties. One such alternative is fiber-reinforced polymer (FRP) bars, which are made of high-strength fibers embedded in a polymer matrix. FRP bars are lightweight, corrosion-resistant, and have a high tensile strength, making them an attractive replacement for steel rebars. They are also non-conductive and non-magnetic, making them suitable for use in areas with electromagnetic interference or in sensitive industries such as electronics. Another alternative is carbon fiber reinforced polymer (CFRP) bars, which are similar to FRP bars but are specifically reinforced with carbon fibers. CFRP bars offer even higher tensile strength and stiffness compared to steel rebars, making them particularly suitable for structures that require exceptional load-bearing capabilities. Furthermore, natural fiber reinforced composites (NFRC) have also been explored as a replacement for steel rebars. NFRC can be made from materials such as bamboo, jute, or sisal fibers embedded in a matrix material like cement or polymer. These natural fibers offer good tensile strength and can be a sustainable and cost-effective alternative to steel rebars, especially in regions where these fibers are abundantly available. In conclusion, while steel rebars have been the traditional choice for reinforcement materials in construction, alternatives such as FRP bars, CFRP bars, and NFRC can be viable substitutes. The choice of reinforcement material depends on various factors such as structural requirements, environmental conditions, and cost-effectiveness.

- Q:How do steel rebars affect the overall cost of maintenance and repairs?

- Steel rebars can significantly impact the overall cost of maintenance and repairs. These reinforcement bars enhance the strength and durability of concrete structures, reducing the likelihood of cracks, deterioration, and structural failures over time. By preventing such issues, steel rebars minimize the need for extensive repairs and maintenance, ultimately lowering associated costs in the long run.

- Q:What is the impact of steel rebars on the overall carbon footprint of a building?

- Steel rebars have a significant impact on the overall carbon footprint of a building. The production of steel involves high energy consumption and releases a substantial amount of greenhouse gas emissions, primarily carbon dioxide. The extraction and processing of iron ore, as well as the manufacturing and transportation of steel rebars, contribute to the carbon footprint of a building. The carbon footprint of steel rebars is further influenced by the extent of the rebar usage in the building. The more steel rebars used, the higher the carbon footprint will be. The size and complexity of the structure, as well as the specific design requirements, will determine the quantity of steel rebars needed. However, it is important to note that steel rebars are an essential component of reinforced concrete, which is widely used in construction due to its strength and durability. Reinforced concrete provides structural integrity and ensures the safety and longevity of a building. So, while steel rebars contribute to the carbon footprint, they also play a crucial role in constructing safe and resilient structures. To mitigate the carbon footprint associated with steel rebars, several strategies can be employed. One approach is to use recycled steel rebars, which significantly reduces the energy consumption and emissions associated with steel production. Additionally, optimizing the design and construction process can help minimize the overall amount of steel required, thereby reducing the carbon footprint. Moreover, alternative materials such as fiber-reinforced polymers (FRPs) are being developed as substitutes for steel rebars. FRPs have lower carbon footprints, as they are made from materials such as fiberglass or carbon fiber, which have lower emissions during production. However, the use of FRPs is still limited, and further research and development are needed to increase their viability as a mainstream alternative. In conclusion, steel rebars have a notable impact on the overall carbon footprint of a building due to the energy-intensive production process and emissions associated with their extraction, manufacturing, and transportation. However, their crucial role in providing structural integrity and durability must be considered. Efforts to reduce the carbon footprint of steel rebars include using recycled materials, optimizing designs, and exploring alternative materials such as FRPs. Ultimately, a holistic approach that considers both the environmental impact and the structural requirements of a building is necessary to minimize the carbon footprint associated with steel rebars.

- Q:What are the sizes available for steel rebars?

- Steel rebars, also known as reinforcing bars, come in various sizes to suit different construction needs. The sizes available for steel rebars typically range from #3 to #18. Each size is denoted by a number, which corresponds to the diameter of the bar in inches. For example, a #3 rebar has a diameter of 3/8 inch, while a #18 rebar has a diameter of 2 1/4 inches. These sizes are standardized and commonly used in construction projects worldwide. The choice of rebar size depends on factors such as the structural requirements, load-bearing capacity, and specific engineering specifications for a particular project. The larger the diameter of the rebar, the higher its strength and load-bearing capacity. It is important to note that the availability of sizes may vary depending on the region or country, as different standards and regulations may be followed. It is always recommended to consult local building codes and engineering professionals to determine the appropriate size of steel rebars to be used in a construction project.

- Q:Can steel rebars be used in underwater structures?

- Underwater structures can indeed utilize steel rebars. In construction projects, steel rebars are frequently employed to reinforce and enhance the strength and stability of concrete structures. For underwater structures like bridges, dams, and offshore platforms, the utilization of steel rebars is essential due to their exceptional durability and strength. Nevertheless, employing steel rebars in underwater structures necessitates additional factors. Corrosion is a significant concern, as exposure to water and salt can expedite the corrosion process. To mitigate this issue, corrosion-resistant steel rebars, such as stainless steel or epoxy-coated rebars, are utilized. These rebars possess protective layers that prevent direct contact between the steel and water, thereby minimizing the risk of corrosion. Moreover, adequate design and construction techniques are crucial when incorporating steel rebars into underwater structures. Sufficient concrete cover and appropriate spacing between rebars are pivotal to ensure ample protection against corrosion and maintain the structural integrity of the underwater structure. Additionally, regular inspection and maintenance are imperative to identify and rectify any signs of corrosion or deterioration in the rebars. In conclusion, careful consideration of corrosion protection measures and adherence to proper design and construction practices are necessary when employing steel rebars in underwater structures. With the implementation of adequate precautions, steel rebars can furnish the requisite strength and durability for underwater structures.

- Q:Can steel rebars be used in buildings with high architectural requirements?

- Yes, steel rebars can be used in buildings with high architectural requirements. Steel rebars provide the necessary strength and structural integrity required for such buildings, while also allowing for flexibility in design and construction. They can be easily shaped and bent to meet specific architectural demands, ensuring both functionality and aesthetic appeal in the building's design.

- Q:Can steel rebars be used in coastal construction?

- Yes, steel rebars can be used in coastal construction. Steel rebars are commonly used in coastal construction due to their high strength and durability. They have excellent resistance to corrosion, which is crucial in coastal areas where the presence of saltwater and high humidity can lead to accelerated corrosion of building materials. Additionally, steel rebars can withstand the forces of the waves and strong winds typically experienced in coastal regions. They are able to provide the necessary structural support for buildings, bridges, seawalls, and other coastal infrastructure. However, it is important to ensure proper protective measures are taken, such as using corrosion-resistant coatings or stainless steel rebars, to further enhance their durability and longevity in coastal environments.

- Q:Can steel rebars be used in thin concrete elements?

- Yes, steel rebars can be used in thin concrete elements. However, it is important to carefully consider the design and placement of the rebars to ensure they provide sufficient reinforcement without compromising the structural integrity or aesthetic appearance of the thin concrete element. Additionally, proper construction techniques and quality control measures should be followed to ensure the rebars are correctly positioned and embedded within the concrete.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Tensile Deformed Steel Rebar Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords