High Tensile Deformed Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

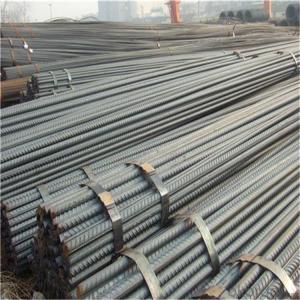

High Tensile Deformed Steel Bar

Description of High Tensile Deformed Steel Bar

1, Diameter: 5.5mm-10mm High Tensile Deformed Steel Bar

10m- 40mm High Tensile Deformed Steel Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

2, Produce Process:

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of High Tensile Deformed Steel Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of High Tensile Deformed Steel Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:How does bearing steel resist fatigue?

- Bearing steel resists fatigue due to its high strength, hardness, and excellent resistance to wear and impact. It is specifically designed to withstand repeated loading and stress cycles without undergoing deformation or failure. Additionally, the steel's microstructure is carefully engineered to enhance its resistance to fatigue by distributing stress evenly and minimizing the formation of cracks or fractures.

- Q:Can special steel be used for making electrical components?

- Indeed, electrical components can indeed be crafted using special steel. Special steel denotes a collection of steels boasting distinct properties and features that render them fitting for diverse uses, including electrical components. These steels are frequently tailored to possess exceptional electrical conductivity, minimal electrical resistance, commendable magnetic traits, and outstanding heat endurance. They are commonly employed in electrical engineering scenarios where utmost performance and dependability are indispensable, such as the production of transformers, motors, generators, and electrical transmission systems. Furthermore, special steel can also furnish protection against corrosion and elevated temperatures, thereby augmenting its aptness for the manufacturing of electrical components.

- Q:How is special steel used in the packaging industry?

- Special steel is widely used in the packaging industry for its exceptional strength, durability, and corrosion resistance properties. It is commonly utilized to manufacture packaging materials such as cans, containers, and closures. Special steel ensures the safety and integrity of products during storage and transportation, while also allowing for efficient and cost-effective packaging solutions.

- Q:How does special steel perform at high temperatures?

- Special steel is designed to maintain its strength and resistance to deformation even at high temperatures. It exhibits excellent heat resistance, high thermal conductivity, and retains its mechanical properties, making it ideal for applications that require stability and durability in extreme heat environments.

- Q:How does special steel contribute to the safety of infrastructure?

- The safety of infrastructure is greatly enhanced by special steel in several ways. Firstly, it possesses exceptional strength and durability, allowing for the construction of strong and resilient structures. Bridges, buildings, and tunnels can rely on special steel to withstand heavy traffic, strong winds, seismic activities, and even potential terrorist attacks. Furthermore, special steel exhibits excellent resistance to corrosion, making it ideal for infrastructure projects exposed to harsh environmental conditions. By preventing rust and decay, it prolongs the lifespan of structures and reduces the need for costly maintenance and repairs. This is particularly crucial in coastal areas, where saltwater can cause significant damage. Moreover, special steel has outstanding fire resistance due to its high melting point. This characteristic ensures that structures maintain their structural integrity even under extreme temperatures. In the event of a fire, this feature allows for additional time for evacuation and emergency response, thereby enhancing overall safety. Additionally, special steel enables innovative design solutions, further contributing to infrastructure safety. Its versatility allows for the creation of complex and efficient structures such as long-span bridges and skyscrapers. These designs often incorporate special steel components, such as high-strength beams or columns, which enhance overall stability and safety. In conclusion, special steel is an essential material for ensuring the safety and reliability of infrastructure. Its exceptional strength, corrosion resistance, fire resistance, and design flexibility enable engineers and architects to create structures capable of withstanding various challenges. By utilizing special steel in construction projects, lives and well-being of people who utilize these structures can be effectively protected.

- Q:What are the different coating techniques used for special steel?

- There are several different coating techniques used for special steel, including electroplating, hot-dip galvanizing, powder coating, and thermal spray coating. Each technique has its own advantages and uses, depending on the desired outcome and the specific properties of the special steel being coated.

- Q:How does special steel compare to other materials like aluminum or titanium?

- Special steel is known for its exceptional strength, durability, and resistance to corrosion, making it a popular choice for various applications. Compared to materials like aluminum or titanium, special steel often offers superior strength and toughness, making it suitable for heavy-duty industries such as construction, automotive, and aerospace. While aluminum is lightweight and has good corrosion resistance, it may lack the necessary strength for certain demanding applications. Titanium, on the other hand, is lightweight and possesses excellent strength-to-weight ratio, but it is more expensive and difficult to process than special steel. Ultimately, the choice between special steel, aluminum, or titanium depends on the specific requirements of the application at hand.

- Q:What are the properties of special steel?

- Special steel has several unique properties that make it highly desirable in various industries. Firstly, it possesses exceptional strength and durability, allowing it to withstand high levels of stress, pressure, and temperature. This property makes it suitable for applications in construction, automotive, and aerospace sectors where strength and reliability are crucial. Additionally, special steel offers excellent corrosion resistance, ensuring its longevity even in harsh environments. It is also known for its excellent machinability, weldability, and formability, making it easy to work with and shape into desired forms. Furthermore, special steel exhibits good magnetic properties, making it ideal for use in electrical components and magnetic devices. Overall, the properties of special steel make it a versatile material that can be customized for specific applications, offering exceptional performance and reliability.

- Q:Can special steel be used in automotive engine components?

- Yes, special steel can be used in automotive engine components. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as increased strength, toughness, and heat resistance. These properties make it ideal for use in critical engine components that are subjected to high temperatures, stress, and wear. In automotive engines, special steel can be used in various components such as crankshafts, camshafts, connecting rods, valves, and piston rings. These components are subjected to extreme conditions, including high temperatures, pressure, and rotational forces. Special steel provides the required strength and durability to withstand these conditions, ensuring reliable engine performance and longevity. The use of special steel in automotive engine components offers several advantages. Firstly, it increases the strength and load-carrying capacity of the components, allowing them to handle higher power and torque outputs. Secondly, special steel improves the fatigue resistance and durability of the components, reducing the risk of failure and extending their service life. Lastly, special steel can withstand the high temperatures and thermal cycling experienced in the engine, preventing deformation and maintaining dimensional stability. Overall, the use of special steel in automotive engine components is crucial for achieving optimal performance, reliability, and longevity. It ensures that the engine can withstand the demanding conditions it operates under, providing a smoother and more efficient driving experience.

- Q:What are the different surface defects in special steel?

- There are several different surface defects that can occur in special steel. Some of the common defects include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of steel during the manufacturing process. It can appear as a flaky or powdery substance and can be caused by exposure to high temperatures or improper cooling. Scale can affect the appearance and quality of the steel surface. 2. Pitting: Pitting is the formation of small, localized holes or depressions on the surface of the steel. It can be caused by corrosion, improper cleaning or surface preparation, or exposure to harsh environments. Pitting can weaken the steel and make it more susceptible to further corrosion. 3. Scratches: Scratches are physical marks or indentations on the surface of the steel. They can occur during handling, transportation, or processing of the steel. Scratches can affect the appearance and integrity of the steel surface and may need to be repaired or removed. 4. Roll marks: Roll marks are impressions or patterns left on the steel surface during the rolling process. They can appear as lines, grooves, or ridges and can be caused by uneven pressure or improper alignment of the rolling equipment. Roll marks can affect the surface smoothness and may require additional processing or polishing to remove. 5. Inclusions: Inclusions are foreign particles or substances that are embedded within the steel. They can be caused by impurities in the raw materials or contamination during the manufacturing process. Inclusions can weaken the steel and may lead to cracks or fractures. 6. Decarburization: Decarburization is the loss of carbon from the surface layer of the steel. It can occur during heating or annealing processes, and it can result in reduced hardness and strength of the steel surface. Decarburization is usually undesirable in special steel as it affects its performance. These are just some of the surface defects that can occur in special steel. It is important to identify and address these defects to ensure the quality and performance of the steel product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Tensile Deformed Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords