high temperature resistance silica fiber cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Silica fiberglass cloth is one high-temperature inorganic fiber with the molten temperature nearly 1700 degree Celsius, and the work for a long time at 900 degree Celsius.

Application:

Widely used as heat resistant and ablationresistasant material for rocket,missile and space vehicle;

High-temperature resistant,thermal insulation,refractory material;

Dust collect for high temperature gas;

Liquid filtration;Sound absorbing and thermal insulation for vehicle,motor bicycle;The thermal insulation protective materials for molten liquid filtration.

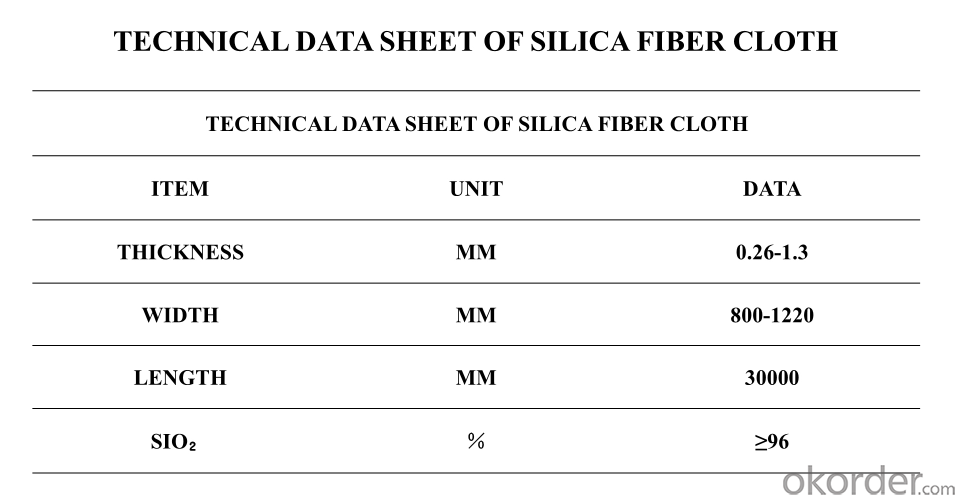

Product Capability:

SiO2>=96%;

High temperature resistant,higher thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

Data Sheet:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q:Can fiberglass fabric be used for reinforcement in boat decks?

- Yes, fiberglass fabric can be used for reinforcement in boat decks. Fiberglass fabric is known for its strength, durability, and resistance to corrosion, making it an ideal material for boat construction. It can add structural integrity to boat decks, providing reinforcement and enhancing their overall strength. Additionally, fiberglass fabric is lightweight, which is advantageous for boats as it helps to maintain buoyancy and fuel efficiency. Furthermore, fiberglass fabric is highly resistant to water and weather conditions, making it suitable for marine environments. Overall, fiberglass fabric is a popular choice for reinforcing boat decks due to its strength, durability, corrosion resistance, and lightweight properties.

- Q:How is fiberglass fabric used in the production of thermal curtains?

- Fiberglass fabric is commonly used in the production of thermal curtains due to its unique properties and benefits. Firstly, fiberglass fabric is known for its excellent insulating properties, which makes it a perfect material for thermal curtains. The fabric acts as a barrier against heat transfer, helping to maintain a stable temperature inside a room. In the production of thermal curtains, fiberglass fabric is often used as a lining or an interlining. It is sandwiched between the decorative outer fabric and the inner lining of the curtain. This layer of fiberglass fabric adds an extra layer of insulation, preventing heat loss in the winter and heat gain in the summer. Additionally, fiberglass fabric is lightweight and flexible, making it easy to work with during the manufacturing process. It can be easily cut, sewn, and tailored to fit various curtain sizes and designs. Moreover, fiberglass fabric is durable and long-lasting, ensuring that thermal curtains made from this material will withstand frequent use and maintain their insulating properties over time. Furthermore, fiberglass fabric is fire-resistant, adding an extra layer of safety to thermal curtains. This property is crucial in preventing the spread of fire and protecting occupants in case of an emergency. Overall, fiberglass fabric is an essential component in the production of thermal curtains. Its insulating, lightweight, flexible, durable, and fire-resistant properties make it an ideal choice for creating curtains that effectively regulate temperature, conserve energy, and enhance comfort in homes and commercial spaces.

- Q:Is fiberglass fabric resistant to UV degradation?

- Yes, fiberglass fabric is generally resistant to UV degradation. Fiberglass is made from fine glass fibers that are woven together to form a fabric. These glass fibers possess inherent properties that make them highly resistant to the harmful effects of UV radiation. UV rays from the sun can cause degradation and discoloration of many materials over time, but fiberglass fabric is designed to withstand prolonged exposure to sunlight without significant damage. The glass fibers in the fabric are not affected by UV rays, making fiberglass fabric a durable and long-lasting material for outdoor applications. However, it is important to note that prolonged exposure to intense UV radiation can still cause some level of degradation over an extended period. Therefore, it is recommended to take appropriate care and maintenance measures, such as regular cleaning and occasional application of UV protectant coatings, to ensure the longevity of fiberglass fabric in outdoor settings.

- Q:Can fiberglass fabric be used for making filters?

- Indeed, filters can be made using fiberglass fabric. Renowned for its exceptional toughness and long-lasting nature, as well as its capability to endure elevated temperatures, fiberglass fabric proves to be an outstanding selection for filter purposes. The fabric can be skillfully woven into diverse dimensions and forms, enabling tailoring to satisfy specific filtration needs. Furthermore, fiberglass fabric exhibits remarkable resistance against chemicals and corrosion, rendering it suitable for utilization across a broad spectrum of sectors, including automotive, aerospace, and industrial realms. In summary, fiberglass fabric emerges as a dependable and efficient substance for the creation of filters.

- Q:What is the difference between woven and non-woven fiberglass fabric?

- The main difference between woven and non-woven fiberglass fabric lies in their structure. Woven fiberglass fabric is made by weaving individual glass fibers together, creating a strong and flexible material. On the other hand, non-woven fiberglass fabric is produced by bonding or felting glass fibers together using adhesives or heat, resulting in a denser and less flexible fabric. While woven fiberglass provides better strength and durability, non-woven fiberglass is often preferred for applications that require higher stiffness and dimensional stability.

- Q:Is fiberglass fabric suitable for outdoor use?

- Yes, fiberglass fabric is suitable for outdoor use. Fiberglass is known for its exceptional durability and resistance to various environmental factors such as sunlight, moisture, and temperature fluctuations. It is also highly resistant to chemicals, making it suitable for outdoor applications where exposure to harsh weather conditions or chemicals is expected. Additionally, fiberglass fabric is lightweight, flexible, and easy to handle, making it an ideal choice for outdoor products such as awnings, canopies, boat covers, and outdoor furniture upholstery. Its heat resistance and fire-retardant properties also make it a safe option for outdoor use. Overall, fiberglass fabric is a reliable and widely used material for outdoor applications due to its strength, durability, and resistance to various outdoor elements.

- Q:Can fiberglass fabric be used for making protective sleeves?

- Indeed, protective sleeves can be crafted using fiberglass fabric. Renowned for its durability, heat resistance, and capacity to endure soaring temperatures, fiberglass fabric proves to be an exceptional option for such sleeves, particularly in industries where laborers confront intense heat or perilous substances. By furnishing a dependable shield against heat, flames, chemicals, and abrasions, fiberglass fabric effectively safeguards the wearer's arms from potential harm. Moreover, its lightweight and flexible nature ensure the wearer's comfort and facilitate effortless mobility.

- Q:What are some popular brands of fiberglass fabric?

- Some popular brands of fiberglass fabric include Owens Corning, 3M, Hexcel Corporation, Saint-Gobain, and Jushi Group. These brands are well-known for their high-quality fiberglass fabrics that are used in a wide range of industries such as automotive, aerospace, construction, and marine. Owens Corning, for example, is a leading manufacturer of fiberglass materials and offers a variety of fabric options for different applications. 3M is another trusted brand that provides fiberglass fabric with excellent thermal resistance and durability. Hexcel Corporation is known for its advanced composite materials, including fiberglass fabrics, which are highly sought after in the aerospace industry. Saint-Gobain is a global leader in fiberglass fabric production, offering a wide range of specialty fabrics for various industries. The Jushi Group is one of the largest producers of fiberglass in the world and supplies high-quality fiberglass fabrics to global markets. These popular brands are known for their commitment to quality and innovation, making them trusted choices for fiberglass fabric needs.

- Q:Can fiberglass fabric be used for insulation in clean rooms?

- Fiberglass fabric, indeed, finds great utility in clean rooms as an insulation material. Renowned for its remarkable thermal and acoustic properties, it is commonly employed for insulation purposes. Its remarkable resistance to heat transfer and capacity to diminish noise render it ideal for establishing a controlled and insulated atmosphere within clean rooms. Furthermore, fiberglass fabric boasts qualities such as being lightweight, long-lasting, and impervious to chemicals and moisture, all of which are crucial factors to consider in clean room applications.

- Q:Can fiberglass fabric be used for airbags?

- Airbags can indeed utilize fiberglass fabric. Renowned for its durability and ability to resist heat, fiberglass fabric proves suitable for endeavors demanding both safety and endurance. Given their pivotal role in vehicle safety, airbags must endure immense impact and rapid inflation. Fortunately, fiberglass fabric endows them with the necessary strength and resilience to handle such demanding circumstances. Moreover, this material boasts a lightweight and flexible nature, allowing it to be easily molded into diverse shapes, rendering it an ideal choice for airbags. In conclusion, fiberglass fabric stands as a highly reliable and frequently employed material for airbags, thanks to its exceptional strength-to-weight ratio and capacity to withstand the harshest of conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high temperature resistance silica fiber cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords