high temperature resistance silica chopped fiber cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

It is high temperature resistant product.Mixed a ratio of organic fiber in the chopped silica fiberglass and put into fiberglass or stainless steel wire as reinforcement to spun the yarn,and then woven into the cloth.(stainless steel wire or fiberglass reinforced)

Application:

As the external insulation layer for industrial furnaces and other external heat preservation and heat insulation for a variety of mechanical equipment and pipeline;

As welding spark cloth for building,ship,large construction equipment industry;

Fireproof and heat indulation for rail vehicle,vehicle transportation insulation parts;

Can be processed into the fire-proof curtain in the building ,fireproof garment( covered aluminum),fireproof gloves,fireproof shoes,etc.

Product Capability:

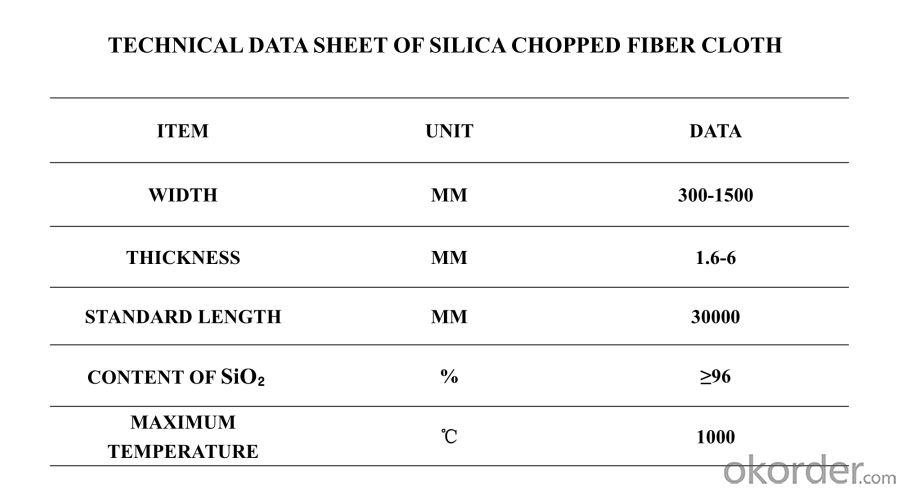

SiO2>=96%;

Compared with the traditional high silica fiberglass cloth,the advantage of this cloth is that can be reinforced with stainless steel wire,have strong resistance performance,can be folded,thick and light weight,high air tightness;

The skin irritation is very small,no dust,can replace the traditional ceramic fiber cloth;

Higher temperature resistant,insulation,low heat conduction rate;

High thermal and chemical stability,good dielectric properties.

Data Sheet:

Silica fiber products:

A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q:What is waterproof, one cloth, four coated?

- The operation includes the steps of: primary processing - additional waterproof glue brush again, dry brush second times, glue, and laying a layer of glass cloth after work, brush third times rubber - dry, brush fourth times rubber - water test.

- Q:What are the high temperature resistant fiberglass fabrics made in China?

- Before, domestic and foreign countries have a big gap. Later, with the upgrading of domestic technology, some large glass fiber enterprise production products and foreign countries have been comparable.

- Q:Can fiberglass fabric be used for medical devices?

- Yes, fiberglass fabric can be used for medical devices. It is commonly used in applications such as wound dressings, orthopedic casts, and splints due to its lightweight, high strength, and flexibility. Furthermore, its biocompatible properties make it suitable for medical use as it does not cause any adverse reactions or allergies in patients.

- Q:Can fiberglass fabric be used for making backpacking or camping gear?

- Yes, fiberglass fabric can be used for making backpacking or camping gear. Fiberglass is a strong and durable material that is resistant to tears and abrasions, making it suitable for outdoor activities. It is also lightweight, which is essential for backpacking where every ounce matters. Moreover, fiberglass fabric has excellent insulation properties, providing warmth when used in sleeping bags or blankets. Additionally, fiberglass is water-resistant, making it suitable for use in tents or shelters to protect against rain or moisture. Overall, fiberglass fabric is a versatile material that can be used in various camping and backpacking gear to enhance durability, insulation, and protection.

- Q:Can fiberglass fabric be used for making heat shields?

- Yes, fiberglass fabric can be used for making heat shields. Fiberglass fabric is known for its excellent heat resistance properties, making it an ideal material for heat shielding applications. It can withstand high temperatures without melting or deforming, providing a protective barrier against heat transfer. Additionally, fiberglass fabric is lightweight, flexible, and has good insulation properties, making it suitable for various heat shield applications, such as in automotive, aerospace, and industrial settings.

- Q:Is fiberglass fabric suitable for use in automotive interiors?

- Yes, fiberglass fabric is suitable for use in automotive interiors. Fiberglass fabric is known for its durability, strength, and resistance to heat and fire. These characteristics make it an excellent choice for automotive interiors, where it can withstand the wear and tear of daily use and provide a high level of protection. Fiberglass fabric is commonly used in automotive interiors for various purposes. It can be used as a reinforcement material for the seats, headliners, door panels, and other interior components. Its high tensile strength ensures that the fabric can withstand the pressure and stress placed on these parts, ensuring their longevity. Additionally, fiberglass fabric is often used as a sound and heat insulator in automotive interiors. Its thermal properties help to reduce heat transfer, keeping the cabin cooler in hot weather. It also helps to dampen sound vibrations, providing a quieter and more comfortable driving experience. Furthermore, fiberglass fabric is resistant to moisture, mold, and mildew, making it ideal for use in automotive interiors that are exposed to varying weather conditions. It is also easy to clean and maintain, which is crucial for maintaining the aesthetics and functionality of the interior components. Overall, fiberglass fabric offers numerous advantages that make it suitable for use in automotive interiors. Its strength, durability, heat resistance, and insulating properties make it a popular choice among manufacturers and designers looking to create high-quality, long-lasting, and comfortable automotive interiors.

- Q:Is fiberglass fabric resistant to staining or discoloration?

- Yes, fiberglass fabric is generally resistant to staining or discoloration. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to form a fabric. This fabric is known for its durability and resistance to various external factors, including staining and discoloration. The smooth surface of fiberglass fabric makes it difficult for stains to penetrate and adhere to the fabric. Additionally, fiberglass fabric is often treated with special coatings or finishes that enhance its resistance to staining and discoloration. However, it is important to note that the level of resistance can vary depending on the specific type of fiberglass fabric and any additional treatments or coatings it may have. Therefore, it is always recommended to consult the manufacturer's guidelines for proper care and maintenance to ensure the longevity and appearance of fiberglass fabric.

- Q:What are the different finishing options available for fiberglass fabric?

- There are several finishing options available for fiberglass fabric, including laminating, coating, and impregnating. Laminating involves applying a layer of resin to both sides of the fabric, which enhances its strength and durability. Coating refers to the process of applying a thin layer of protective material on the fabric's surface, such as latex or silicone, to improve its resistance to abrasion or chemicals. Impregnating involves saturating the fabric with a liquid resin or coating, which allows it to bond with other materials or provide additional properties such as flame resistance or waterproofing.

- Q:How is fiberglass fabric sewn?

- When sewing fiberglass fabric, a heavy-duty sewing machine with a strong needle and thread is typically used. The process involves aligning the fabric panels' edges and passing them through the machine, allowing the needle to pierce through the layers and create stitches. It is important to use a sharp needle specifically designed for sewing fiberglass fabric because this material can be tough and abrasive, potentially causing regular needles to break or become dull quickly. Additionally, using a sturdy thread, such as polyester or nylon, is crucial to ensure the durability and longevity of the seams. Skill and precision are required when sewing fiberglass fabric since the material can be slippery and difficult to handle. It is recommended to practice on scrap pieces before attempting to sew large or complex projects.

- Q:How to use silica gel cloth and glue?

- The former is nylon, glass fiber and other materials on the coating of liquid silicone rubber, and its bonding can be used at room temperature, slow dry glue

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high temperature resistance silica chopped fiber cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords