High Temperature refractory Mortar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Characteristic:

1.High modulus of rupture

2.Not easy to fall off

3.Short bonding time and less use

![]()

This product is produced by chemical reaction .Added more than two kinds of additives .The product has two kinds of shape:liquid and powder.The liquid product can be used directly .But the powder product should be add water and heat into paste.

![]()

| Item | JTHM-1450 | JTHM-1550 | JTHM-1700 |

| Classification temperature °C | 1450 | 1550 | 1700 |

| Bulk density g/cm3 | 1.7 | 1.9 | 2.0 |

Modulus of rupture Mpa (dried at 100°C) | 12 | 20 | 18 |

| Al2O3 % | 35 | 60 | 70 |

| Fe2O3 % | 1.3 | 1.2 | 0.9 |

| Quantity for KG/1000 bricks | 180 | 200 | 200 |

![]()

This product is widely used in ceramic fiber products,high-alumina insulation bricks,mullite insulation bricks,corundum insulation bricks and the products of not easy to bond when masonry .

Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.

Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

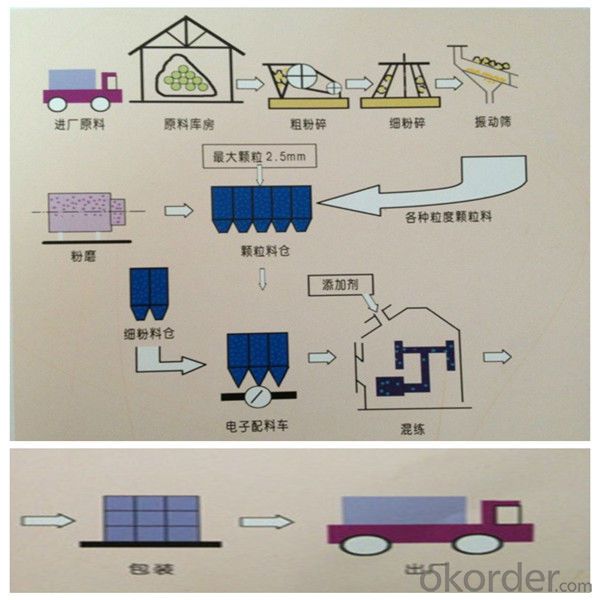

Process flowdiagram:

FACTORY:

- Q:How to deiron refractory?

- Our company uses magnetic separation method.

- Q:What are the qualifications of refractory industry?

- 1 business license 2 tax registration certificate 3 organizing institution bar code 4 production permit

- Q:What advantage and disadvantages it has compared to common fire insulation materials

- Main advantage of A-level fire proof heat retaining plate is A-level non-conbustibility. Now residential areas strictly require the external walls to be high-level fire proof, to be specific, high fire resistance, non combustible. Standards for evaluation varies according to different types, which includes anti-corrosion, acid and alkali resistance, waterproof, anti termites and so on. Disadvantage is the insulation effect is quite ordinary. It will absorb water, get deformed, need some water prevention measures after constrcuting thermal insulating layer for it. Its thermal conductivity far below the benzene plate, and plastic extruded palte, half the thickness of the polyurethane insulation layer can reach heat perservation effectiveness of the benzene plate and extruded plate of the same thickness.

- Q:What is the interior fireproof thermal insulation material?

- The methods of thermal insulation wall have three kinds of materials. First: gypsum board or cement board are stuck outside the polyphenyl board; second: lightweight brick build; third: infill polyphenyl board, lightweight brick is built outside. The first two has almost the same price. The latter is slightly expensive. 60 yuan / square meter is not very expensive!

- Q:What refractories are accessible with ease in daily life?

- Basically there have all materials. But it depends on your needs.

- Q:What kind of fireproof material is used for steel structure?

- Brushing or spraying the coating on the surface of steel structure to prevent burning and insulate heat. It also prevents undermining the rolled steel from rapid temperature elevation and avoid collapse of building for lose of supporting capacities. Agglutination material are classified as fireproof coatings for steel structures which is solvent based and Water-based steel structure fire retardant coatings. Fireproof coatings for steel structures which is solvent based are subdivided into fireproof coatings for steel structures which is solvent based with low benzene content and fireproof coatings for steel structures which is solvent based with high benzene content (TVOC≤600g / L, benzene ≤5g / kg). It can be divided by thickness. ultra-thin (CB) fireproof coatings (coating thickness ≤3mm), thin (B) fireproof coatings (3mm & amp; lt; coating thickness ≤7mm) and thick (H) steel structure fire retardant coating (7 mm & amp; lt; coating thickness ≤45㎜).

- Q:How to hang the suspended brick in the refractory masonry?

- First you can fasten the girder and the suspended brick with screws, and then move them to the specified location by a crane. You can contact the refractory plant in Shanshan mountain, Ningxiang Countym, Hunan Province at 0731-7150098.

- Q:Are there any differences between insulation and refractory materials ?

- First, refractory materials can resist more than 1200 degrees, some of which are not insulation materials, such as firebricks, which can directly contact with heat source, has little insulation effect. Ceramic fiber, high silica, etc. are all refractory materials which can insulate. Second, insulation materials with poor performance usually is lower than 800 degrees, which have large thermal resistance, and low thermal conductivity, high porosity. Thus they reduce the thermal loss. To put it simply, insulation materials store most of the heat and only let a small part of heat lose through the air, thus the heat has been isolated. Glass fiber, rock wool, flexible material for thermal insulation, etc.

- Q:What are the differences between thermal?insulation?material and refractory?

- Just as its name implies, Thermal insulation means that it doesn't conduct heat instead it insulates heat inside, while refractory means resistance to high temperature and it will not be out of shape or damaged due to high temperature.

- Q:What needs to be paid attention to in the construction of high- temperature refractory mortar?

- 1. During the use of high- temperature refractory mortar, the minimum mortar joint should be 0.5mm and general mortar joint should be 3-5mm, which can solve the processing and fine grinding of refractory brick on the brick grinder. Besides, it is conducive to the health of workers, and can reduce the masonry effort, ensure the quality and speed up the construction progress. 2. When making urgent repair on the stove, if the joint is much too large, 2-3mm refractory pieces can be appropriately added into the high- temperature refractory mortar, and stirred to fill the joint so as to shorten the repair time and ensure normal production. 3. High- temperature refractory mortar can be painted inside various furnace body, and it should be guaranteed that the surface of the furnace body has no dust or debris before painting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature refractory Mortar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords