High Temperature Insulation Kevlar Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRICE: USD10 per square meter

UNIT: square meter

MOQ: 500 square meter

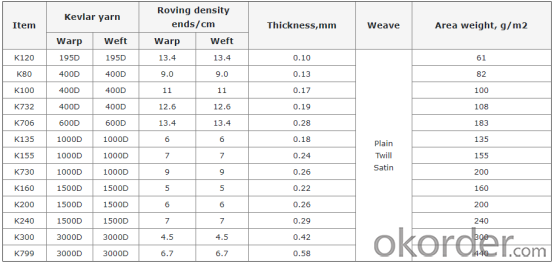

Weight: 50-460gsm

Width: 1-1.8m

Roll length: 100 meters or customized

Weave Type:plain, twill

Material: fiberglass

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Description: Kevlar® fabric is made by kevlar continuous filament fiber yarn. The kevlar is a famous brand of Dupont. Currently, there are available with K29, K49, part of K129 fabrics.

For economic purpose, we also supply China local supplier's para aramid fiber yarn.

Application: High strength lamination; Bulletproof; Fireproof

- Q:Can fiberglass fabrics be used for protection against electromagnetic interference?

- Yes, fiberglass fabrics can be used for protection against electromagnetic interference. Their low electrical conductivity and excellent dielectric properties make them effective as shielding materials, blocking or reducing the penetration of electromagnetic waves.

- Q:How is fiberglass fabric used in the sports and recreation industry?

- Fiberglass fabric is widely used in the sports and recreation industry for its strength, durability, and flexibility. It is commonly used in the manufacturing of sports equipment such as fishing rods, hockey sticks, and tennis rackets, where it provides enhanced performance and resistance to breakage. Additionally, fiberglass fabric is also employed in the production of protective gear, such as helmets and body armor, due to its ability to absorb impact and provide excellent protection.

- Q:Is fiberglass fabric flame resistant?

- Yes, fiberglass fabric is flame resistant. It is made from glass fibers that have been woven into a fabric. The glass fibers have a high melting point, which makes the fabric highly resistant to catching fire or melting. This makes fiberglass fabric a popular choice in applications where flame resistance is important, such as in insulation, protective clothing, and fireproof curtains. However, it is important to note that while fiberglass fabric is flame resistant, it is not completely fireproof. It may still burn if exposed to high temperatures for prolonged periods of time.

- Q:What is the typical warp and weft count of fiberglass fabrics?

- The specific application and desired strength and durability can cause variations in the warp and weft count of fiberglass fabrics. Generally, fiberglass fabrics tend to have a higher warp count compared to the weft count. This is because the warp yarns, running vertically, are thicker and stronger to ensure stability and resistance against stretching and tearing. Conversely, the weft yarns, running horizontally, are thinner and more flexible to allow the fabric to conform to different shapes and contours. The warp count for fiberglass fabrics typically ranges from 16 to 40 yarns per inch, while the weft count is slightly lower, ranging from 12 to 30 yarns per inch. These counts can also be measured in metric units, like yarns per centimeter. However, it's important to note that these counts may vary depending on the specific manufacturer, fabric weight, and intended use of the fiberglass fabric.

- Q:Can I put up wall tiles on the bathroom wall waterproof cloth?

- Non-woven fabric, which is similar to a cloth that will base with cement mortar thin brush layer, it can be directly laid on the top.1, note: these three, no matter what kind of waterproof, around 300-500 higher than the ground to prevent water flowing along the wall to the following:1, brush the first waterproof coating. Before construction, make sure that the site is clean and dry, waterproof paint should be painted, no missing, and firmly integrated with the base, no cracks, no bubbles, no shedding phenomenon. Brushing height is consistent, the thickness should meet the product specification requirements.2, brush second times waterproof coating. Note that the first and second times waterproof paint between the need for a certain time interval, the first time after the dry coating can be carried out second times, the specific time depends on the paint. Interval time is too short, waterproof effect will be greatly reduced.3, laying protective layer. To prevent subsequent construction damage to the waterproof layer, it is necessary to put a protective coating on the surface of waterproof coating. The protection layer should be covered with waterproof layer without any omission. It is firmly integrated with the base layer, without cracks, no bubbles and no shedding.

- Q:With what glue can stick glass steel cans?

- The modified epoxy adhesive can stick to the FRP tank;In addition to the epoxy resin and other non-polar polyolefin plastic adhesive is not good, for all kinds of metal materials such as aluminum, steel, iron, copper; non metallic materials such as glass, wood and concrete; and thermosetting plastics such as phenolic, amino, unsaturated polyester has excellent adhesive properties, so it is called monengjiao. Epoxy adhesive is an important kind of structural adhesive.

- Q:Do fiberglass fabrics have any electrical conductivity properties?

- No, fiberglass fabrics do not have any electrical conductivity properties.

- Q:Is fiberglass fabric resistant to fading?

- Yes, fiberglass fabric is highly resistant to fading. Its composition and manufacturing process make it durable and less prone to color fading caused by sunlight exposure or regular use.

- Q:Are fiberglass fabrics suitable for use in the telecommunications industry?

- Yes, fiberglass fabrics are suitable for use in the telecommunications industry. They offer excellent electrical insulation properties, are lightweight, durable, and resistant to corrosion, making them ideal for various applications such as insulation, cable management, and antenna construction.

- Q:How to deal with cracks in floor construction joints?

- Cracks in the surface coating: coated on the surface of the seal coating or protective mortar, general with glass fibre cloth as the reinforced layer, sealing coating with polyurethane or epoxy resin protective mortar with polymer mortar or neoprene latex mortar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature Insulation Kevlar Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords