High Temperature Castable Refractory Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 40000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

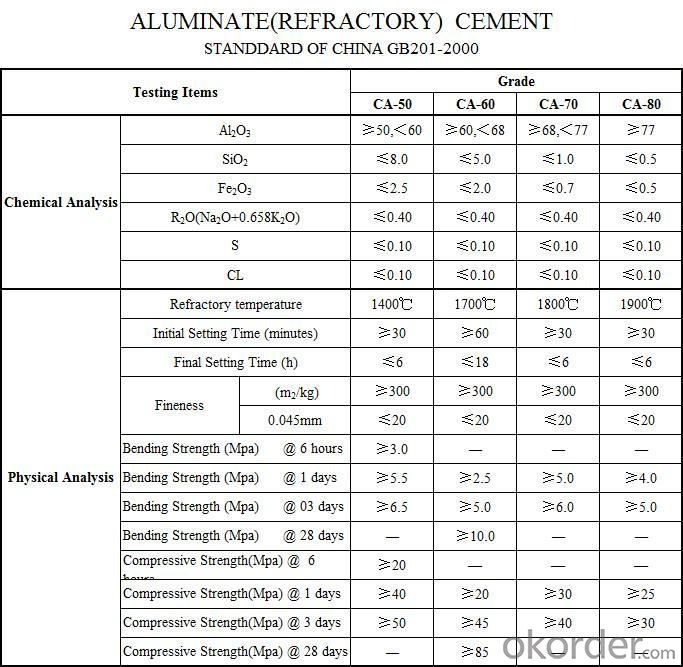

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM | Model Number: | CA-50 |

| Color: | Brown | Feature: | Refractory | Main Raw Material: | Aluminate |

| Type: | refractory cement | Hardening Feature: | Rapid Hardening | Heat of Hydration: | Moderate Heat |

| type: | Refractory cement | Al2O3: | ≥50<60< p=""> | Refractory temperature: | 1400 ℃ |

Packaging & Delivery

| Packaging Details: | a) 50kg per bag then 40 bags into a 2mt sling bag for portland cement 42.5R b) 2mt jumbo bag of portland cement |

| Delivery Detail: | within 25 days after received payment |

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | QIHAN | Model Number: | CA-50 |

| Color: | Brown | Feature: | Refractory | Main Raw Material: | Aluminate |

| Type: | refractory cement | Hardening Feature: | Rapid Hardening | Heat of Hydration: | Moderate Heat |

| type: | Refractory cement | Al2O3: | ≥50<60< p=""> | Refractory temperature: | 1400 ℃ |

Packaging & Delivery

| Packaging Details: | a) 50kg per bag then 40 bags into a 2mt sling bag for portland cement 42.5R b) 2mt jumbo bag of portland cement |

| Delivery Detail: | within 25 days after received payment |

Specification

Packaging & Shipping

“ Come on! you need try and trust ”

We are forwarding hand in hand together, win-win future!

We always provide the best service!

SGS inspection before shipment

- Q:Who know what kind of fire shutter fire rating are there?

- There is no national standard for fire protection performance of fire roller shutter in China, and now the executive standard of GB14102-2005 "fire shutter": F1, fire-resistant time 1.50h; F2, fire-resistant time 2.00h; F3, fire-resistant time 3.00h; F4, fire-resistant time was 4.00h before the national standards of fire shutter grading is introduced, expert advice that fire resistance test be made according to national standard, to reach back fire surface temperature rise requirements, if the refractory limit is greater than or equal to 3.0h, it is said to be super fire shutter, if test not inspect unexposed surface temperature rise as a judgement of the conditions, the door is referred to as ordinary fire shutter doors. I hope my answer can help you

- Q:What is refractory aggregate?

- It includes two categories: coarse aggregate and fine aggregate.

- Q:I wanna ask about the thermal insulation material fire resistant level?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. Thanks

- Q:What are fireproofing materials?

- Plants often use the fireproof sealing material with steel structures without much modification. All the panels that meet the first-order fire protection requirements can be fireproofing materials. Like gypsum boards, aluminum sheets and so on. . Coatings are usually those with fine powder, high density and good sealing. Hardeners mainly depends on specific requirements. .

- Q:Which kind of furnace hearth refractory is better?

- Coal is acidic medium, so the matched material should be acidic refractories oriented, like silica?bricks. For example, the coking coke oven and carbon furnace made of carbon are in reducing atmosphere, so they use silica bricks which have low price and good high-temperature indicators. If the part has special requirements, you can then consider other refractory on request.

- Q:What is the difference between wear-resistant material and refractory material?

- Focus is different. Some materials are called wear-resistant and refractory material. For example, refractory castable with high strength and wear-resistance, impressionable plastic material or brick. They all begin with fire-resistance and wear-resistance.

- Q:what's the fireproof levels of fireproof and thermal inuslation matertial?

- thermal insulation refractory material is also known as thermal insulation material, it has low thermal conductivity, average is below 0.3 w/m ℃). porosity is in commonly above 50%, bulk density is less than 1300 kg/m3 with low mechanical strength. thermal insulation refractory material, according to the operating temperature, can be divided into three kinds of materials: high temperature thermal insulation material (< 1200 ℃), medium temperature thermal insulation material (900 ~ 1200 ℃) and low temperature thermal insulation material (< 900 ℃). According to the bulk density, it can be divided into: general thermal?insulation?material (bulk density

- Q:Why the corundum can be used as refractory

- It can resiatant to friction wear.The alumina material is a kind of neutral material with high temperature resistance, anti-acid, anti-corrosion, alkali resistance, and high hardness of corundum. The disadvantage is the poor thermal shock resistance, the main chemical composition of corundum is aluminium oxide and the melting point of corundum is 2080 degrees

- Q:What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material.

- Q:What parts of cement kilns are refractories used on?

- In kilns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature Castable Refractory Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 40000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords