High Temperature 1600c Polycrystalline Mullite Ceramic Fiber Blanket for Iron Making Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Temperature 1600c Polycrystalline Mullite Ceramic Fiber Blanket for Iron Making Furnaces

Ceramic Fibre Blanket Discription

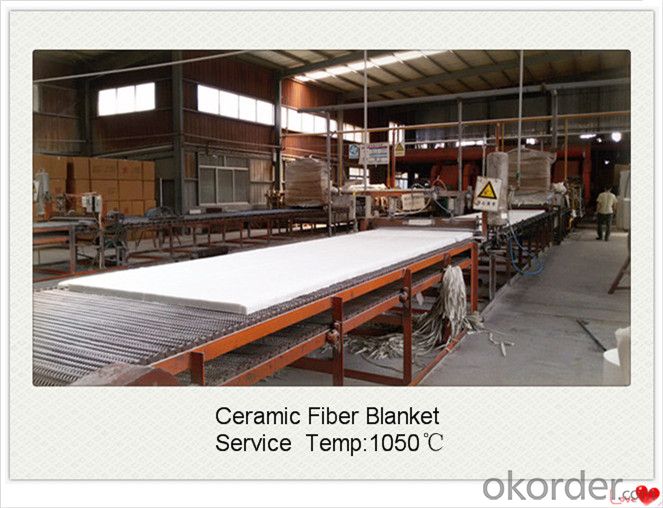

Ceramic fiber product is made from high quality Gao-ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. No chemical binder is added. Double-side needling provides blanket with great tensile or handing strength for easy installation.

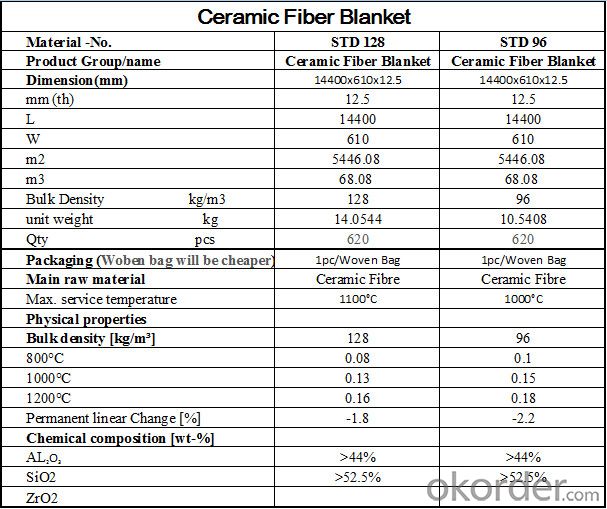

There are four kinds of ceramic fiber products according to the temperature and chemical content. They are STD(1260℃),HP(1260℃),HA(1350℃, high alumina),HZ(1430℃,contain ZrO2).

1) For the blanket, the bulk density will be 64kg/m3, 96 kg/m3, 128 kg/m3, 160 kg/m3.

2) For the paper, the bulk density will be 160-220 kg/m3.

3) For the board, the bulk density will be 240-400kg/m3.

Ceramic fiber blanket, board,cloth and textiles are made from high quality clay, high purity alumina and silica oxides by spun or blown process.

Ceramic fibre blanket, board and cloth have a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fibre insulation blanket also has difference,and they are suitable for different workong temperatures.

Ceramic fibre blanket, board and cloth can be used after optional cutting .When ceramic fibre insulation blanket storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Packaging & Delivery

Each Roll/Case:12.5*610*14400mm, 25*610*7200mm, 50*610*3600mm

Characteristics of Ceramic Fibre Blanket

1)Low thermal conductivity

2)High tensile strength

3)Resilient to thermal shock

4)Corrosion resistance

5)High-purity type

6)High-temperature refractory

7)Al Content (%): 32-55

8)Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

9)Density: 64-160kg/m3

10)Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Applications of Ceramic Fibre Blanket

1.Industrial furnace, heating devices, high temperature pipe

2.High building fireproof ,sound-absorbing and thermal insulation material

3.Thermal insulation material for the electricity boilers, gas turbine and nuclear power.

4.Wall linings of the chemical high-temperature reaction equipment and heating equipment.

5.Thermal insulation for the furnace door and roof.

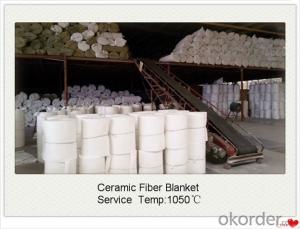

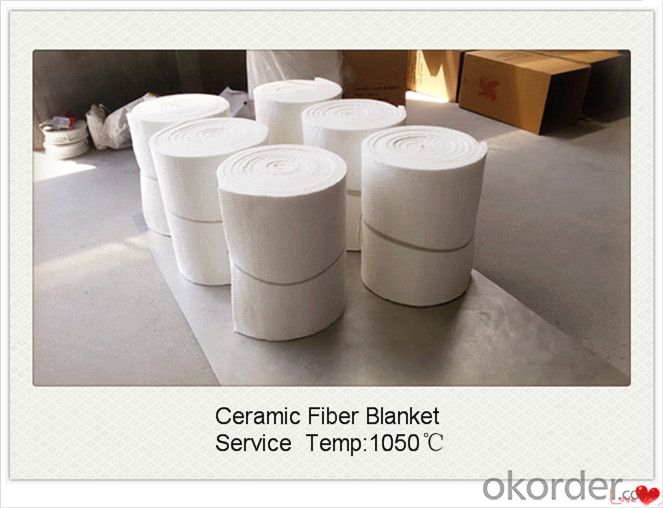

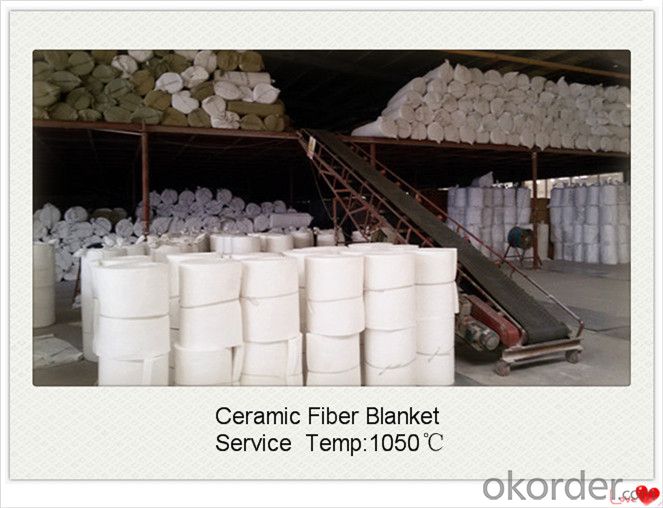

Images

Technical data of Ceramic Fibre Blanket

FAQ

Q1:Are you a manufacturer or trader?

A:Manufacturer+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different ceramic fiber is unlike.It also depends on your using condition and method.

- Q:european yarn labels (knitting)?

- can't tell you the weights but further down on each page is the gauge for needle size/rows and stitches - presumably for a 10cm square

- Q:I baught this cereal at the supermarketIt's made in England, called Dorset CerealsIt's a blend of toasted cereals and the other stuff mentioned aboveThey mention no added salt or sugarHigh in fibre, low in sodium and suitable for vegetariansIncludes wheat, malt, flame raisins, toasted and malted oat flakes, dates, sunflower seeds, toasted coconut, apricots, preservative: sulphur dioxide and roasted hazelnutsWhat do you think? Yes or No?

- There is a reason for it to be blowing the fuseThere is a short some place in itIf you connect the two wires together you may start a fireTo check the switch to see if it is the cause of the short you just need to connect the two wires on it together and replace the fuseIf the fuse still blows then it is not the switch and is some place else and you need some one to check it out.

- Q:Where can I find fabric (fake fur) that looks like Boober's fur in Fraggle Rock?

- If you want to install additional insulation it should be on the floor of the attic NOT against the roofYou can lay fiberglass bats in the opposite direction of the existing bats and over the joists, it should be non faced bats, meaning no paper backingThe attic is supposed to be a cold space and Dan is right about the issues he addressed.

- Q:i heard they use a lot of water out of your bodyi know there not good for, i eat healthy and workout im 116 anyways im on my period so im really bloated and want it to go away for 4th of julyi do have problems going to the bathroom eating a lot of fiber dosent help me that much all i eat is high fiber foods mostly

- Sailboats are dismantled and transported by truck all the timeRemove the mast and the keel and you are good to go.

- Q:My boyfriend really wants a purple zebra print blanket for his birthday but all I've been able to find is a regular black and white zebra print oneI was thinking of just buying that one and then dying it purple with something like an at home tie dye kitThe one I found is this like a plush blanket and it's really soft.What worries me though is after I dye the blanket will it be less soft or will it still feel the same?Also the color won't bleed or fade when he washes it right?

- it has nothing to do with amount of sodium, fiber or the fact that they are called diet YOU HAVE TO COUNT CALORIES!!! find calorie/fitness calculator on the net, enter all your stats and it will tell you how many calories a day you need to maintain your weighttake 300-400calories off that number and thats how many you need to lose weightwork out - cardio 4-6 times a week for 30-50min plus light weight training 8 glasses of water a day 5-8 servings of fruit and vegetables a day instead of big meals eat 5-6 small meals a day (portion control) no junk food, no bleached flower (e.g.white bread, pasta), no sodas

- Q:someone gave me several skeins of quot;virgin woolquot; fingering weight sock and sweater yarnit's relatively itchy and a plain grey colour, I wasn't sure what made it quot;virgin woolquot; and what I should use it for.

- lying from you- linkin park diary of jane-Breakinq benjamin

- Q:I was wondering what the real affects of adding fiber to your diet areI was watching a show once and a nutritionalist said that after you consume X amount of gms of fiber you can eat a choc chip cookie for example and not worry about the bad stuff in itDoes this statement hold any merit or is it completely bogus?

- Fiber in your diet is very beneficial to a persons health for many reasonsIt will help in moving food through the colon faster, to help protect against constipation, spastic colon, colon cancer and hemorrhoidsGet a wide variety of fiber though through a varied dietGum and pectin fiber decrease fat absorption and lower cholesterol levelsThey also slow sugar absorption which is helpful to diabeticsYeah it's good for you and a cookie after a high fiber meal probably isn't as bad for you as if you hadn't had the fiber.

- Q:I have been healthy for five years and love it but I always had a cheat day on SundayWell, 20 days ago I decided to stop cheating and now I seemed to be constipated, and little gassyMy stools are pasty.Did the pizza, ice cream and burgers every Sunday keep me regular?

- Electrical supply houses sell an all weather heavy gage (thicker walled) Aluminum conduit pipe Please make sure that you buy the heavier gage exterior -all weatherAs these should be able to take either the fresh or salt water environmentsThese pipes range in diameter from 1 inch all the way up Best Wishes Wayne

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature 1600c Polycrystalline Mullite Ceramic Fiber Blanket for Iron Making Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products