High strength road & landfill constructions tri-dimension compound geonet for drainage,filteration,

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

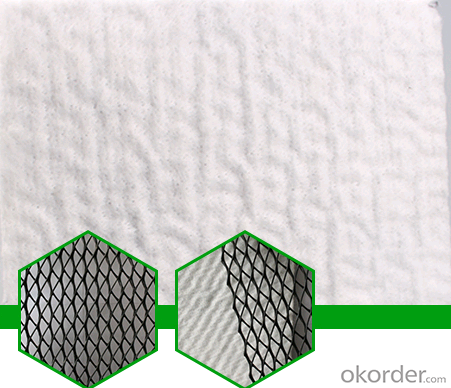

Tri -dimension composite geonet / geonets and geocomposites

Be made of tri-dimension geonet coated geotextile on both sides, has the property of geotextile (filtration) and geonet (drainage and protection), and has the complete function of "filtration--drainage-- protection"

Application

landfill drainage

hignway roadbed

railaway drainage

tunnel drainage

underground structure drainge

retaining walls drainage

garden and playground drainage

Feature

- stronger drainage function and can bear high press load for a long time

- high tensile strength and shear strength

- keep stable water conductivity

- can bear compression load of more than 2000kpa

- larger anti-compression capacity than common geonet

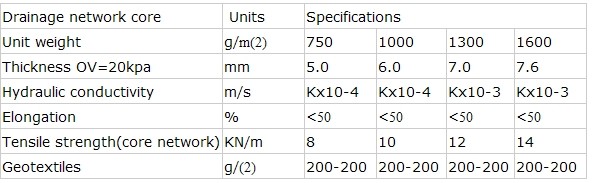

Tri-dimension composite geonet technical specifications

- Q:How do geomembranes provide water retention in green roof systems?

- Geomembranes provide water retention in green roof systems by acting as a barrier that prevents water from draining off the roof surface. The impermeable nature of geomembranes helps to hold and store water within the green roof system, allowing plants to access it for nourishment and reducing the need for additional irrigation.

- Q:Can geomembranes be used in mining applications?

- Yes, geomembranes can be used in mining applications. They are often utilized for lining tailings ponds, heap leach pads, and other containment systems in the mining industry. Geomembranes provide a reliable barrier to prevent the leakage of potentially harmful substances into the environment and help to protect the surrounding ecosystems.

- Q:What are the requirements for geomembranes used in secondary containment systems?

- Geomembranes used in secondary containment systems must meet certain requirements to ensure their effectiveness. Firstly, they should have excellent chemical resistance to prevent any leaks or spills from contaminating the environment. Additionally, they must possess high tensile strength and puncture resistance to withstand potential damage from external forces. Impermeability is another crucial requirement, as the geomembrane should prevent the passage of liquids or gases. UV resistance is also essential to ensure the longevity and durability of the geomembrane when exposed to sunlight. Lastly, the geomembrane should be flexible and able to conform to the shape of the containment area for proper installation.

- Q:Are geomembranes resistant to UV degradation?

- Yes, geomembranes are resistant to UV degradation. They are specifically designed to withstand exposure to sunlight and UV radiation without significant deterioration or damage.

- Q:How do geomembranes prevent seepage?

- Geomembranes prevent seepage by acting as a barrier between fluids and the underlying soil or substrate. They are made of impermeable materials such as high-density polyethylene or PVC, which do not allow water, gases, or other substances to pass through. The geomembrane is installed in such a way that it forms a continuous lining or cover, effectively preventing the movement or leakage of fluids through the soil or substrate, thus containing and controlling seepage.

- Q:Can geomembranes be used for gas containment?

- Yes, geomembranes can be used for gas containment.

- Q:What are the differences between the geomembrane and the geotextile?

- The geomembraneis is impermeable material made of plastic film as anti-seepage material, and composites with non woven fabric. Its anti-seepage property mainly depends on the anti-seepage property of plastic film. At present, the domestic and foreign anti-seepage plastic films mainly include polyvinyl chloride (PVC) and polyethylene (PE) and EVA (ethylene / vinyl acetate copolymer), design of the tunnel also used ECB (blending geomembrane of ethylene-acetic acid-ethylene modified asphalt), which is a kind of macromolecular chemistry of flexible material, and it features a smaller proportion, good extensibility, high adaptation to the deformation, corrosion resistance, low temperature resistance, and good frost resistance. The geotextileis a permeable composite material made of synthetic fibers, which are made by needling or knitting; its physical structure is multi-layer cloth membrane. Finished products are cloth-shaped, the general width is 4-6 meters, length is 50-100 meters. The geotextile is divided into woven geotextile and non-woven geotextile. The geotextile has the characteristics of excellent filtration, drainage, isolation, reinforcement and protection, with light weight, high tensile strength, good permeability, high temperature resistance, freezing resistance, aging resistance and corrosion resistance.

- Q:How do geomembranes stabilize slopes?

- Geomembranes stabilize slopes by acting as a barrier that prevents erosion and sliding of soil and rocks. They provide a stable surface that holds the slope in place, reducing the risk of landslides and soil erosion. Additionally, geomembranes can also control the flow of water, preventing saturation of the slope and further enhancing stability.

- Q:What products are hdpe waterproof board and HDPE geomembrane?

- hdpe waterproof board and HDPE geomembrane are anti-seepage film of high density polyethylene.

- Q:What are the requirements for geomembranes used in heap leach pads?

- The requirements for geomembranes used in heap leach pads include high chemical resistance to withstand the acidic or alkaline solutions used in the leaching process, excellent puncture and tear resistance to prevent leakage, UV resistance to withstand prolonged exposure to sunlight, and a smooth surface to ensure proper flow of liquids. Additionally, geomembranes must have high tensile strength and elongation properties to withstand stresses and movement in the heap leach environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High strength road & landfill constructions tri-dimension compound geonet for drainage,filteration,

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords