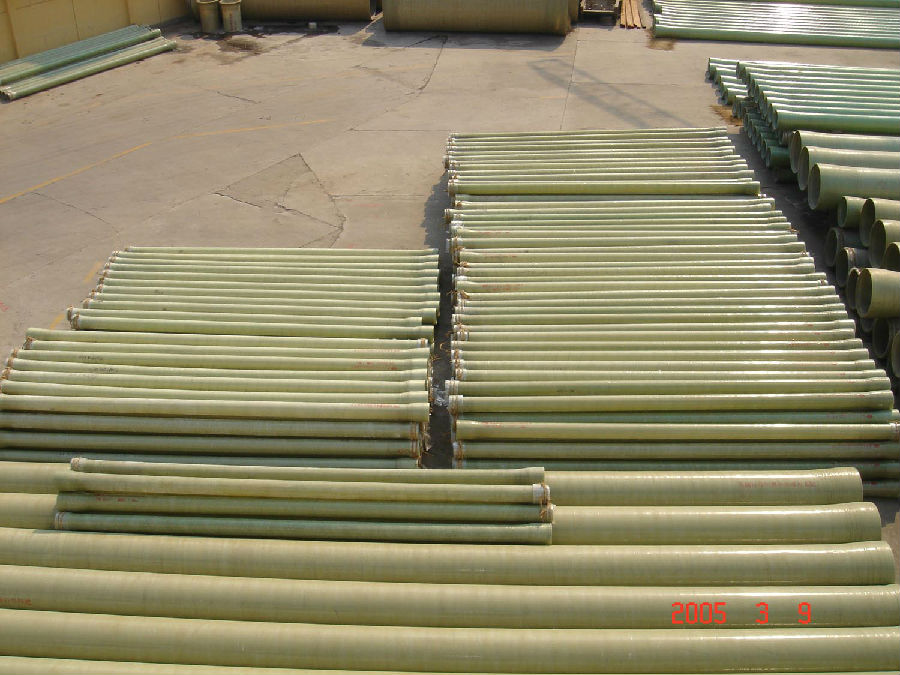

High Strength FRP/GRP Pipe for Water Transportation (DN<0.3m)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

In the FRP .with high tensile strength, the fiberglass plays the role of reinforcement whiles the wear-resistance and pressure –resistance synthetic resin is used for bonding the fiber as the basic materials. Putting together, they commonly play the role of being in finished form and load carrier.

Characteristics:

1. Good physical mechanics performance

2. Being resistant to chemical erosion and longer service life

3. Excellent hydraulic characteristics

4. Lower installation and keeping cost

5. Flexible design and shorter reform term

6. No medium pollution

FRP pipe classification by application field

1. Chemical medium transportation pipe

2.Various producing process pipe (chemical process, paper making process, polluted water treatment process, sea water purifying process, food and drink producing process, and medicine producing process)

3. Pressure pipe for small hydroelectric power station on the ground and cycling pipe for power plant

4. Polluted water collecting and transporting pipe

5. Drink water transporting main line and tubing pipe

6. Oil field water injecting pipe and oil transporting pipe

7. Heat transporting pipe and sea water transporting pipe

8. Agricultural irrigation pipe

9. FRP set (ventilation, air-conditioner, chimney, cleaner) and piping

10. Gas drainage pipe for mine

FRP pipe classification by pressure in working state

1. Medium and low pressure pipe 0.6MPa2.5 MPa

2. High pressure pipe5.5MPa24 MPa

3. Mobile gravity pipe (which can be used when the pressure is under 0.6MPa)

4. Vacuum tube, external pressure pipe or siphon.

FAQ:

1..Is your company a factory or trade company?

A:We have our own factory , we are on this business more than 10 years.

2.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

3.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q:What is the compressive strength of all kinds of FRP materials?

- Heat resistance, frost resistance: at -30 DEG C, still has good toughness and high strength, can be used for a long time in the range of -50 DEG C 80 DEG C, the temperature of resin with special formula can be more than 110 DEG C. 4) of light weight, high strength, convenient transportation and installation by fiberglassreinforcedplastic pipe winding fiber production, the proportion of 1.65 - 2, 1 / 4 only of steel, but the glass steel hoop tensile strength is 180 300MPa, the axial tensile strength of 60 150MPa, similar to alloy steel. Therefore, its specific strength (strength / density) is 2-3 times that of alloy steel, so that it can be designed according to different requirements of users to meet all kinds of internal and external pressure requirements of the pipeline. For the same diameter of single FRP tube, only carbon steel (steel plate) 1 / 2.5, 1 / 3.5 of the cast iron pipe, about 1 / 8 of prestressed reinforced concrete pipe, so the transportation is very convenient for installation. The GRP pipe is 12 meters per length, and can be reduced by 2/3 from the concrete pipe. The socket connection mode of the utility model has the advantages of quick and simple installation, low hoisting cost and improved installation speed. 5) small friction resistance, high transport capacity: glass tube wall is very smooth, roughness and friction resistance is very small. The roughness coefficient is 0.0084, while the n value of concrete pipe is 0.014, and the cast iron pipe is 0.013. Therefore, glass fiber reinforced plastic pipe can significantly reduce the loss of fluid pressure along the course and improve the conveying capacity.

- Q:How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- Do not know the road of glass steel flange have, if any to buy different materials of cast iron flanges or PVCU flange on the same material, the three way behind the pipeline branch, so that the material market has purchased (ABS buy buy in the small town is not easy), the construction is convenient. If it is a glass steel pipe, pipe end cannot change, can only be used to bond the glass steel material, the pipe bonded on the flange is an arc for a plane is bonded with a cast iron pipe flange suggestions. Because the FRP material and most of the plastic are not bonded.

- Q:How is the glass reinforced septic tank and the cement drain pipe connected?

- PE bellows is good, and now they are so connected.

- Q:Where are the advantages of FRP pipes? Long life?

- AntifoulingThe pipe surface using unsaturated polyester resin, so the surface is clean and smooth, not by sea or sewage in a shell, fungi and other microbial contamination of borers, so increasing roughness, reduce cross section, increase maintenance costs. No such pollution, long-term use clean as before.

- Q:What is the stiffness of FRP pipe?

- The ring stiffness is the comprehensive parameter of the tube's resistance to external pressure. Obviously, the choice of ring stiffness is one of the keys to ensure the safe operation of plastic underground drainage pipe under the external compressive load. If the ring stiffness of the tube is too small, the tube may undergo excessive deformation or buckling failure. On the other hand, if the ring stiffness is chosen too high, the excessive cross section moment of inertia must be used, which will result in too much material and too high cost.

- Q:Slurry circulation glass fiber reinforced plastic pipe

- Slurry circulation glass fiber reinforced plastic pipeline has good corrosion resistance. FRP pipes are resistant to acid, alkaline, and non fluid erosion. In general, the service life of the steel pipe is 15 years, the cast iron pipe is 5 - 10 years, and the glass tube can be used for 50 years.

- Q:What is the structure and function of glass fiber reinforced plastic lining?

- The role of FRP lining, corrosion protection, generally attached to the carbon steel container wall, can avoid the use of stainless steel, saving costs. FRP can resist acid and alkali corrosion, PH2-12 or so no problem, but not high temperature, the temperature is higher than 80 degrees, more dangerous, will dissolve.

- Q:FRP pipe and 0.7 thick galvanized pipe which cost is low?

- The best material in glass steel mould rubber production 20 years, customers in all aspects

- Q:Would like to ask about the plastic lined steel pipe, steel pipe, glass steel skeleton, the advantages and disadvantages of each ceramic pipe, to know a friend told, very grateful!

- Plastic lined steel pipe of strong corrosion resistance, heavy quality, need to be made, on-site installation, if the size deviation cannot be installed. The price is more than 5 times more expensive than that of FRP

- Q:How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Use a high strength resin type;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength FRP/GRP Pipe for Water Transportation (DN<0.3m)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords