High Strength, Corrosion Resistant and Fire Resistant Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

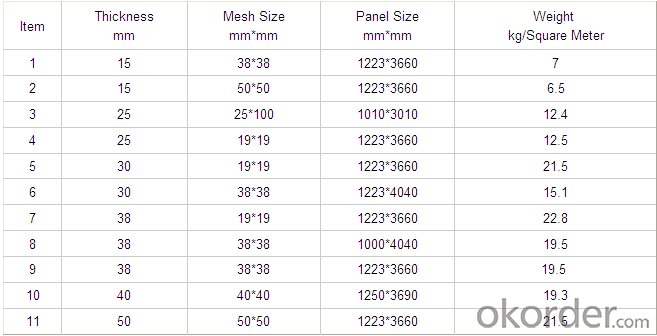

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

2. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

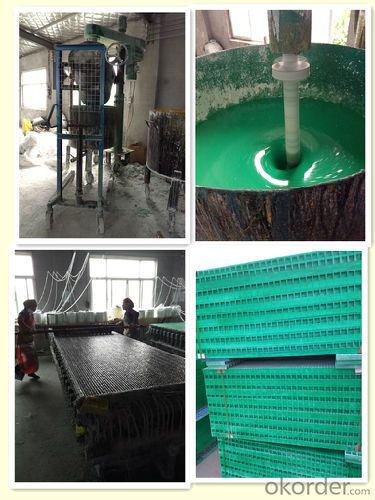

PROCESS

FACTORY

- Q:Can FRP pultrusion profiles be used in aerospace applications?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in aerospace applications. FRP materials have several advantages that make them suitable for aerospace use. Firstly, they have excellent strength-to-weight ratios, which is crucial in the aerospace industry to reduce weight and enhance fuel efficiency. Secondly, FRP materials exhibit high corrosion resistance, making them suitable for prolonged exposure to harsh environments, such as high altitude and extreme temperatures. Additionally, FRP pultrusion profiles offer design flexibility, allowing for complex shapes and geometries to be manufactured. This flexibility enables aerospace engineers to tailor the profiles to specific requirements and optimize performance. Furthermore, FRP materials have low thermal conductivity, which helps in insulation applications and reducing heat transfer. Lastly, FRP pultrusion profiles have demonstrated good fatigue resistance, which is essential for aerospace applications subjected to cyclic loading. Overall, these properties make FRP pultrusion profiles a viable choice for various aerospace components, including structural members, interior parts, and electrical enclosures.

- Q:Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP pultrusion profiles possess notable strength and durability, earning them a reputation in the industry. Their inherent properties make them generally impervious to damage caused by flying debris. This exceptional impact resistance can be attributed to the combination of reinforcing fibers, often fiberglass, and the polymer matrix. The extent of resistance to flying debris impact may vary depending on the design, thickness, and composition of the FRP pultrusion profiles. Nevertheless, these profiles are typically engineered to withstand impact forces and effectively withstand damage from airborne debris. Moreover, FRP pultrusion profiles find extensive use in industries such as construction, transportation, and infrastructure, where impact resistance is of utmost importance. These profiles have undergone rigorous testing and have demonstrated their ability to endure various impact scenarios, making them a trustworthy choice for applications that involve the potential for flying debris. It is vital to recognize that although FRP pultrusion profiles boast commendable impact resistance, the severity of the impact and the speed of the flying debris can still impact the degree of damage incurred. Thus, it is advisable to consult with the manufacturer or an engineer to ensure the chosen FRP profile is suitable for the intended application and potential impact conditions.

- Q:Will the FRP section crack for a long time?

- As long as the design of the structure is reasonable and the quality of the product conforms to the design requirements, the normal use shall not be cracked.

- Q:Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Indeed, FRP (Fiber Reinforced Polymer) pultrusion profiles have the capability to be customized or tailored according to the specific demands of a project. The process of pultrusion, which is employed in the manufacturing, enables the creation of continuous fiber-reinforced composite profiles while providing a considerable amount of design flexibility. By adjusting the design and manufacturing parameters, the dimensions, shapes, and mechanical properties required by a project can be accommodated. The customization procedure commences with a comprehension of the project's needs and specifications. This involves identifying the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can devise a personalized solution. The customization of FRP pultrusion profiles can be accomplished through various methods. Firstly, the selection of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be made based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix utilized in the pultrusion process can be customized to enhance specific properties like fire resistance, chemical resistance, or UV resistance. To meet the project's requirements, different resin systems including polyester, vinyl ester, or epoxy can be utilized. Furthermore, during the manufacturing process, the pultrusion method allows for the incorporation of additional features. This includes the addition of inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. In conclusion, FRP pultrusion profiles offer a significant level of customization and tailoring to cater to the specific demands of a project. This versatility has made them a favored choice in various industries such as construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are essential.

- Q:Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP pultrusion profiles can be used in the construction industry. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability. These profiles can be used in various construction applications such as structural support systems, window and door frames, bridge components, and building facades. They provide a lightweight and cost-effective alternative to traditional construction materials like steel and concrete.

- Q:Can FRP pultrusion profiles be customized according to specific requirements?

- FRP pultrusion profiles can be tailored to specific requirements, offering a wide range of customization options. Pultrusion is a manufacturing process that involves pulling continuous fibers through a liquid resin bath and then curing the resin in a heated die to achieve the desired shape. This process allows for flexibility in design and customization. Customization possibilities for FRP pultrusion profiles include dimensions, shapes, colors, and surface finishes. The dimensions can be adjusted to meet specific length, width, and thickness needs. Shapes can vary from basic geometries like rectangular or round profiles to more intricate designs with unique cross-sections. When it comes to color, FRP pultrusion profiles can be pigmented during manufacturing to achieve the desired shade or can be painted or coated afterward. This allows for matching specific color requirements or ensuring compatibility with existing structures or products. Additionally, surface finishes can be personalized to attain desired properties such as enhanced slip resistance, UV resistance, or fire resistance. Specific performance requirements can be met by applying surface treatments like sanding, coating, or adding special additives. Overall, FRP pultrusion profiles offer a high level of customization, making them suitable for various industries including construction, transportation, infrastructure, and aerospace. They are versatile, lightweight, corrosion-resistant, and possess excellent strength-to-weight ratios.

- Q:Can FRP pultrusion profiles be used in the mining and mineral processing industry?

- The mining and mineral processing industry can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess multiple properties that render them suitable for application in this industry. To begin with, FRP pultrusion profiles are characterized by their lightweight yet remarkably strong composition. This quality makes them ideal for situations where weight reduction holds significance, such as in mining equipment or processing plants. Despite their lightweight nature, FRP profiles can endure substantial loads and withstand corrosion. This is particularly advantageous in the mining industry, where equipment is exposed to harsh environments and corrosive substances. Furthermore, FRP pultrusion profiles are non-conductive with exceptional electrical insulation properties. This proves beneficial in mining and mineral processing operations, where electrical safety takes precedence. FRP profiles can be utilized in scenarios where electrical conductivity must be avoided, such as in electrical enclosures or cable trays. Moreover, FRP pultrusion profiles exhibit high chemical resistance, including resistance to acids and alkalis. This renders them suitable for deployment in mineral processing plants, where various corrosive chemicals are employed in mineral extraction and processing. FRP profiles can withstand exposure to these chemicals without deteriorating or sustaining significant damage, consequently increasing their lifespan and reducing maintenance costs. Additionally, FRP pultrusion profiles possess a high strength-to-weight ratio, enabling the construction of durable and lightweight structures. This proves particularly advantageous in mining operations, where structures like walkways, ladders, and platforms need to be installed in challenging terrains. The lightweight nature of FRP profiles facilitates easier transportation, handling, and installation compared to traditional materials like steel. In conclusion, FRP pultrusion profiles offer a viable option for various applications in the mining and mineral processing industry due to their lightweight composition, high strength, corrosion resistance, electrical insulation, and chemical resistance properties. These profiles present numerous advantages over traditional materials, making them a feasible choice for implementation in this industry.

- Q:What are the typical applications of FRP pultrusion profiles?

- The typical applications of FRP pultrusion profiles include structural components for infrastructure projects such as bridges and buildings, electrical insulation and support systems, corrosion-resistant equipment and storage tanks, ladder and handrail systems, and various other industrial and commercial applications where lightweight, high-strength, and durable materials are required.

- Q:Are FRP pultrusion profiles UV-resistant?

- FRP pultrusion profiles are known for their UV resistance. This is because they are made by combining reinforcing fibers, like glass or carbon, with a polymer matrix, such as polyester or vinyl ester. These materials naturally resist UV radiation, allowing FRP pultrusion profiles to endure long exposure to sunlight without significant deterioration or loss of mechanical properties. However, it's important to note that the UV resistance of FRP pultrusion profiles can vary based on the polymer matrix's type and quality used in their manufacturing. Thus, it is recommended to consult the manufacturer or supplier for detailed information regarding the UV resistance of specific FRP pultrusion profiles.

- Q:Can FRP pultrusion profiles be used in pedestrian bridges?

- Yes, FRP pultrusion profiles can be used in pedestrian bridges. FRP pultrusion profiles offer a number of advantages that make them suitable for bridge construction, including their high strength-to-weight ratio, corrosion resistance, and durability. These profiles are made by pulling continuous fibers through a resin bath and then through a heated die, resulting in a strong and lightweight material. The lightweight nature of FRP pultrusion profiles makes them ideal for pedestrian bridges as they can be easily transported and installed. Additionally, their high strength allows them to withstand the load requirements of pedestrian traffic. These profiles also have excellent resistance to corrosion, which is especially important for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance compared to traditional construction materials like steel or concrete. They are not susceptible to rust or rot, and their non-conductive properties make them safe for use in areas with electrical infrastructure. In summary, FRP pultrusion profiles are a suitable choice for pedestrian bridges due to their lightweight, high strength, corrosion resistance, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength, Corrosion Resistant and Fire Resistant Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords