High Strength Composite Materials AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High strength composite materails AR Glassfiber roving

AR glassfiber is one kind of concrete fiber used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Alkali-resistant(AR) fiberglass is the base material to make Fiberglass Reinforced Cement (GRC), which has been widely used in building industry as board, corrugated proofing sheet, division panel, internal and external insulation panel, decorative panel, dust panel, cable box, granary, channels drainage and garden furniture, artistic sculpture, etc.

Products Features and Advantages

1) Excellent chopped performance and dispersion.

2) Fast and complete wet-out.

3) Low static, no fuzz.

4) Easy roll-out and air release.

5) High mechanical strength.

Technical Data of high strength composite materials Ar glass fiber roving:

PRODUCT NAME | AR- FIBERGLASS CHOPPED STRAND | |||

TEST CRITERION | JC/T572-2002 | |||

TEST ITEM | METERAGE UNIT | STANDARD | RESULT | CONCLUSION |

ZRO2CONTENT | % | ≥16.5 | 16.7 | MEASURE UP |

MOISTURE CONTENT | % | ≤0.2 | 0.1 | MEASURE UP |

TENSILEBREAKING STRENGTH | N/TEX | ≥0.25 | 0.3 | MEASURE UP |

CHOPPED LENGTH | MM | 12±1 | 12 | MEASURE UP |

LINEAR DENSITY | TEX | 98±8 | 99 | MEASURE UP |

COMBUSTIBLE MATTER CONTENT | % | 0.8-2.0 | 1.48 | MEASURE UP |

CONCLUSION | IN CONPLIANCE WITH JC/T572-2002 | |||

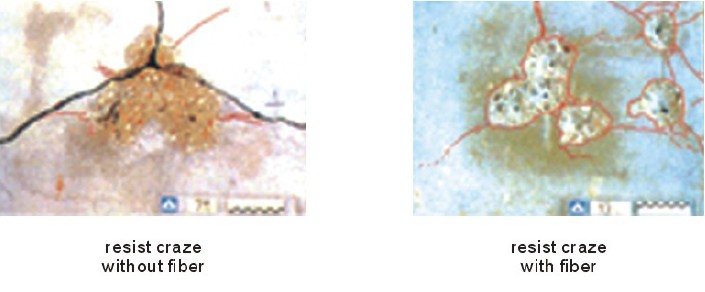

Crack Test:

Packing Style

Each bobbin is 18±1kgs and wrapped by a PVC shrink bag. If required, each bobbin could be packed into a suitable cardboard box.

Each pallet contains 3 or 4 layers, and each layer contains 16 bobbins(4x4). The bobbins in the pallet could be singly piled or be connected as start to end by air spliced or by manual knots.

The whole pallets of bobbins are wrapped with cardboard boxes, packed on the pallet with packing straps and shrink film or with multi-layers of shrink film only.

Storage

This product should be stocked in dry and cool places. The best condition is with temperature between 15 and 35°C, with a relative humidity between 30%-70%. Please keep the product in its original packing before using, avoid moisture.

- Q:What's the qaulity, and how do they look in your opinion.

- The White Cements? If Yea, then YES! Very Nice Shoe, and The Quality Is Very Good, but it really depends on the price they are not worth spending 270+ $ For Them. If you can get them anywhere from under 230$ i would get them

- Q:They all seem to refer to the same thing, is it determined based on how each is used on context or are all interchangeable with each other?

- Asphalt is made from bitumen, a tar like substance. It is mixed with sand and gravel and steam rolled into a flat surface. Also called blacktop. Concrete is a mixture of sand gravel and cement and water that is poured into a mold and set up to dry and harden. Sometimes used with rebar or steel called reinforced concrete. Cement is a dry gray powder sometimes called portland cement that is used to make concrete from. Brick layers use conrete with out rocks just sand added. They call i t mud.

- Q:I am planning on laying vinyl sheet flooring in my kitchen floor. Can I use cement backer board as an underlayment.

- Cement backer board is for use under tile. I have not seen anyone try to put vinyl over it. I would avoid doing this if I were you. 1/4 luan plywood is common for use underneath vinyl flooring. It provides a smooth, uniform surface to work with.

- Q:can you please give me 10 points...

- Below are some reasons why cement industries are important. Cement industries produce Portland cement which is a prime ingredient of concrete for buildings, bridges, canals and roads. For example, The Atlas Portland Cement Company in Hannibal, MO produced much of the cement needed for The Panama Canal and the Empire State Building. Cement is also a key ingredient in stucco, grout and mortar. At the turn of the century, some cement companies also attracted a lot of immigrant workers especially from Europe which in some cases produced new towns or added people to existing towns and helped boost the economy. Modern cement companies rely more on machinery and technology than large labor forces. Cement companies also create quarries which can serve as wildlife habitat when the company is finished with the site. Some cement companies also burn hazardous waste for fuel (which is a good thing as it keeps the hazardous waste from being dumped or buried).

- Q:Home house is rough room, the bathroom is gray walls, do not look good, would like to paste the waterproof stickers instead of tiles. Is it possible to do it? I look online, stickers need to be affixed to the smooth surface, can not be posted in the gray place. What should I do?

- If you want stickers, but the wall, and fall ash, then you go to the building materials market to sell wallpaper to buy a base film shop, 50% of the water brush to the wall, dry, want it It is impossible

- Q:if so, what did you write?I have, last May, and I wrote someone else's phone number. :-PI'm a monster!

- Haha, classic! My sister and I wrote this guy I liked at one points name, Lucas in the cement a couple months ago..then we also put our converse shoe prints on the road too =] ?

- Q:i'm deciding on either white cement 4s 2012, or stealth 3s. i already have military blues but im starting not to like them, however i am not selling them. I reallydnt want another pair of 4s but the white cements are probably one of my favorite jordans. Which should i get?

- Get the white cements

- Q:tomorow we have an activity onquot;how to mix concretequot;in the mix is: cement, sand, gravel and water..we need to know the ratio of this 4 factorsbecause the usual mix that we know isone bag of cement is to 2 cubic foot of sand and gravel...but the question is if wer going to use only 15% of cementwats the ratio with regards to gravel and sand and water

- Hello Claire,, If you mix a cup or a truck load the ratios are the same. For a 3500 psi compressive load its 1 cement to 2 sand 2gravel....Now to be more accurate ,,If you calculate the cubic feet in a cubic yard there is 27 or 3^3...Now when the ASTM set up the Std ratio they based it on cubic feet. A 94lb bag of portland cement is one cubic foot in volume. It has been determined that a 5 sack per cubic yard mix yields 3000 psi compressive strength. A six sack mix yields a 3500lb compressive strength. so actually for 3000 the ratio is 5:27 and 6:27 for 3500 psi.. so for the 3500psi that's 1 cement to 2 1/4 sand and 2 1/4 gravel. When mixing in small batches. LIke your going to do just use a shovel put in 1 shovel of cement 2 sand and 2 gravel. For masonry mortar there are different amounts and materials . A cubic foot is approx equal to 7 shovels full..15% of the bag will take about 2 shovel fulls..A shovel full is subject to the capacity of the person with the shovel..Any way good luck and have fun..from the E

- Q:The front steps of our house were painted with a gray cement paint. I've tried all the chemical I've seen at Home Depot and nothing has worked. Any suggestions?

- Sand blast it, most large construction rental places rent these out. Cement is so porous your going to have a tough time with anything.

- Q:..........without having to make up more cement and putting that over it?I cemented an area on an outside wall and when I checked it a few days later, someone had drawn on it so now it has set and I can't get rid of it. I don't want to have to buy more cement so wondered if there's some way of getting rid of the picture without having to cement over it.

- No...sorry, but I don't think so. But acually I have one idea...you could buy some spray paint thats the same color of the cement and spray paint over it...? I hope I helped!!! :)

1. Manufacturer Overview |

|

|---|---|

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Strength Composite Materials AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords