High Strength and Light Weight Carbon Fiber Tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Carbon Fiber Tube

Our composite tubing, and in particularly our carbon fibre tubes, have significant advantages over most materials in terms of mechanical properties. The table opposite shows comparisons with other common materials.

Property | CF Fabric | CF Uni-Directional | Steel | Aluminium |

Density (g/cc) | 1.60 | 1.60 | 8.0 | 2.7 |

Youngs Modulus 0°(GPa) | 70 | 135 | 207 | 72 |

Youngs Modulus 90°(GPa) | 70 | 10 | 207 | 72 |

Ult. tensile Strength 0°(MPa) | 600 | 1500 | 370 | 240 |

Ult. comp Strength 0°(MPa) | 570 | 1200 | 370 | 240 |

Ult. tensile Strength 90°(MPa) | 600 | 50 | 370 | 240 |

Ult. comp Strength 90°(MPa) | 570 | 250 | 370 | 240 |

As can be seen, carbon fibre has excellent strength and low density. If these two factors are considered together, therefore looking at ‘specific strength’, then the benefits of carbon fibre look even more impressive. This is highlighted in the graph opposite.

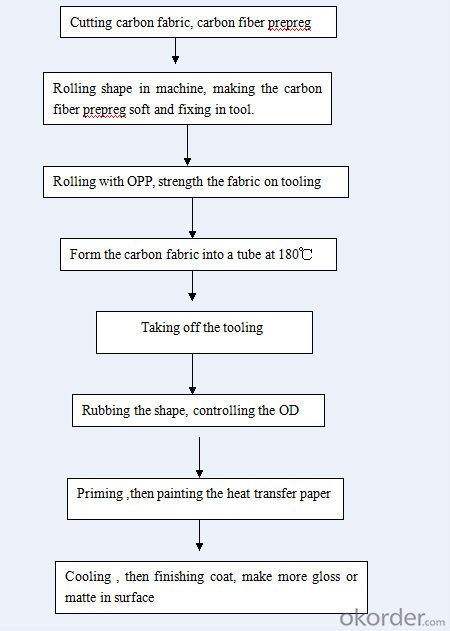

2.Production process

When the laminate has been designed and verified by our engineers the individual patterns are fed to our 5 metre long CNC cutting table which cuts out each pattern precisely. The materials we use are cloths which already have the resin matrix impregnated in to them, known as pre-pregs.

Next, these prepreg layers are wrapped around the male tooling (mandrels) which determine the Inside Diameter (ID) of the tube. These patterns are wrapped in an exact sequence on our machine driven rolling table to ensure consistency and accuracy of the lay-up.

The tubes are then subjected to a high temperature curing cycle under pressure in our electronically controlled ovens and finally removed from the tooling using a hydraulically powered puller mechanism.

Once complete, the raw blank is then ready to be machined and finished in line with the design specification.

The process of carbon fiber tube

3. Features for Carbon Fiber Tube

With over 60 years of collective marine experience we have a significant insight to this industry. This, coupled with our vast knowledge of composites, is invaluable given the diverse nature of composite marine applications.

We produce tubing for all types of marine applications, from small dinghy tiller extensions, paddle shafts, and spars up to one-off tubing for large yacht masts.

The flexibility of our manufacturing process is one of our distinctive qualities in this area:

Able to make tapered tubing which is ideally suited for mast applications.

We can make oval tubing often sought after for masts or booms requiring differential properties in different axes.

Tubes are made with epoxy resin systems which have virtually zero water absorption making them more suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

We have in-house paint facilities and are able to finish tubes with UV stable paint systems, protecting the tubing against inevitable long exposure to the elements.

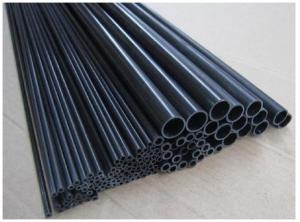

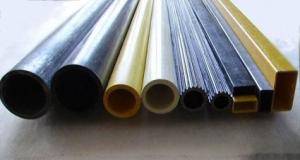

4. Photos for Carbon Fiber Tube :

- Q:hi i have a problem my 89 f150 has a broken leaf spring mount/shacklebut how do i remove it ITS STUDDED IN its a 1989 ford f150 thanks for looking please help me with this

- The answer is yes. It will get you skinny, but you will build up a tolerance and need to take more and more risking addiction, which will eventually make you lose your teeth, looks, freedom (jail) and risking overdose (death).

- Q:Thread style, whether it is the need for screws or something!What do I need to connect the two pipes to the groove joint?!Because I don't have much points, I hope you have some knowledgeable people to help me. Thank you very much!

- The wire connection and screw connection pipeline engineering: the form of thread docking between two pipes, valves, pipes and valves are connected or.

- Q:Outside the wire (wire) of what the standard joint size

- Structure and characteristics:The utility model relates to a sleeve type metal hose joint, which can connect a steel pipe without a thread and a hose, and can save the thread filling process, and only screws can be screwed in;The metal fittings are jacketed to connect the metal hose to the non threaded steel tube;Adaptation: steel thin steel wire pipe, black, tin pipe (water, gas);When choosing the ferrule type metal joint, please pay attention to the specification and size of the connecting pipe hose.Installation notesIn our daily life, we often see the pipe fittings on the pipe fittings. For this kind of products, we need effective installation to ensure that it can perform its functions better. Here is a brief discussion of a kind of pipe joint - card sleeve type joints in the installation of the use of methods.

- Q:I'm looking for a good pair of running tights without any bells and whistles. I'm not interested in any of this tech stuff, so no mesh behind the knees, no zippers on the calves, no reflective material, just basic black spandex. I'd like relatively heavy/sturdy spandex to keep me warm in 40F weather, and I might consider the fleece-lined type also.Could anyone suggest a brand and style? I'm a fan of Nike bottoms (their tops are awful!), so I looked at their website a bit and couldn't find anything as simple as what I want, so maybe I'm just missing something? I'd be happy with men's or women's styles.About 8 years ago, I bought some really simple men's Nike spandex and they were perfectafter seven years, they still felt like new. Unfortunately, I lost them and I'm trying to replace them. Thanks for any help!

- yes you can do this, there are Special fittings that can connect both of them together, but you have to have tread on them.

- Q:How do I distinguish the rigid clamp joint and the flexible clamp joint from the outward appearance?

- Length and thickness of flexible clamps.Clamp itself difference:Flexible and rigid joints of the same specifications: width is different, flexibility is wider than rigidity 2MM (take 159 clamps as an example)

- Q:How to remove the pipe connection, the joint is ring, and there is a spring similar to the oil seal. Not a common joint, wrench removed, ask the teacher to answer

- 2. Disassemble the outdoor machine copper pipe joint and disconnect the outdoor mechanical and electrical connector (remember the order of the lines).3. Remove the indoor and outdoor units.

- Q:1. Which one would u rather have on yur fantasy team?2. Which one is a better RB?

- Galvanized Best answer I could find was , hope the site helps

- Q:Can the pressure vessel pipe joint adopt G thread? Why?

- The pipe thread is on the wall of the pipe for connecting threads. It has 55 degrees of unsealed pipe thread and 55 degree sealing pipe thread. The utility model is mainly used for the connection of pipelines, and the internal and external threads of the utility model are closely matched with two kinds of straight pipes and a conical pipe

- Q:Has anyone (other than firefighters) ever been taught how to use fire extinguishers?

- Go to and ele. supply an ask for a seal off fitting we use them on gas pumps. Its like a coupling but has a plug on the side so you can put sealer in to stop gas fumes from going into the electoral room.

- Q:An accidential fire alarm was triggered at work and when I got out of the building I placed a call to 911. (Like the sign on the outside of the building says) 911 says its a false alarm bt they have to send the fd anyways. I tell my boss and when get back from lunch he says I'm being officially repromanded bcuse the fire department had to do an inspection that closed the building down for about 45 minutes. He stated that the floor marshal decides if the fire department or 911 needs to know.Can they actually legally repromand me?Can

- u need a 1 1/2 to 1 1/4 '' reducer

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength and Light Weight Carbon Fiber Tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords