High sound absorption material rock wool blanket with wire mesh Water repellent,asbestos fre

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

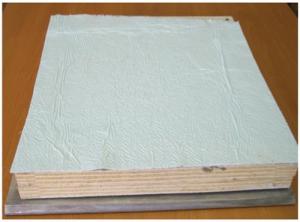

CNBM rock wool blanket with wire mesh Overview:

CNBM rock wool blanket with wire mesh is a robust insulation product stitched on one side with galvanized or stainless steel wire mesh and comes in various thickness and density.

CNBM rock wool blanket with wire mesh Product Specifications¼

Density(kg/m3) | Width(mm) | Thickness(mm) | Length(m) | Facing |

60-150 | 600 | 30-200 | 2.5 , 3 , 5 | wire mesh |

We can make special production according to your requirement.

Rock Wool Blanket With Wire Mesh Technical Parameters:

Item | Unit | Index | Standard |

Density | Kg/m3 | 60-200kg/m3 | GB5480.3 |

Average value of fiber | um | 4-7 | GB5480.4 |

Slag ball content (granule diameter) | % | 6 | GB5480.5 |

Volume water absorption | % | 2 | GB/GB16401-1996 |

Heat absorption | % | 1 | GB5480.7 |

Moisture resistivity | % | 98 | B10299-88 |

- Q:Who knows what is the process flow of FRP splicing water tank?

- The SMC single board with stripping stroke is used for polishing and examining the single board. After checking, the single board is pressed in place and the installation hole is put in storage. Then, the single plate, the glue bar and the stainless steel bracket are combined to form a water tank.

- Q:In recent years, what new materials have come into use in the automotive interior, or in the future?

- LFT is a kind of advanced fiber reinforced lightweight materials in the field, with design, low density, high specific strength, high specific modulus and strong impact resistance and other characteristics, it appears to Aluminum Alloy, fiber reinforced thermoset composites poses huge challenges, and gradually become the mainstream material production of auto parts.LFT Long-Fiber Reinforce is English Thermoplastic, Chinese for long fiber reinforced thermoplastic plastics, used to call the long fiber reinforced thermoplastic composites, it is a kind of advanced fiber reinforced lightweight polymer material field.

- Q:Composite manhole cover or cast iron well cover?

- The raw material of the composite manhole cover is made of resin, which is cheaper than the increasingly scarce steel material, so the color composite manhole cover is cheaper than the cast iron manhole cover.

- Q:Seeking better SMC manufacturers in the industry, it is best to write more, thank you!

- SMC is divided into domestic joint venture factory production, pure Japanese imports on these two, domestic production of product quality with pure Japanese production has certain differences, but not very big, layman see.

- Q:Does floor heating emit toxic gas?

- In the ceramic tile surface drops the right amount of water, after a period of time, looks at the ceramic tile bottom surface whether has the seepage phenomenon, if does not have, is the high grade ceramic tile, if has, is inferior ceramic tile

- Q:How is glass fiber reinforced plastic water tank made?

- FRP hand lay up tank: made of resin glass cloth paste hand processing tank frame surface

- Q:What material is SMC? Can it replace ceramics? Can it be made into toilets, basins, urinals and so on?

- SMC composite is Sheet molding compound abbreviation, that is, sheet molding compound. The main raw materials are made up of GF (special yarn), UP (unsaturated resin), low shrinkage additive, MD (filler) and various auxiliaries. It first appeared in Europe in the early 1960s, and developed in the United States and Japan around 1965. At the end of 80s, China introduced advanced SMC production line and production process abroad.

- Q:What is polymer composite cable trench cover plate?

- From the point of view of cost performance, the general FRP grille grille cover is more economical and durable.This answer is recommended by the questioner

- Q:Is the gas released from the heating of the SMC sheet poisonous?

- SMC sheet is made of unsaturated polyester resin, glass fiber and aluminium hydroxide powder by certain process

- Q:What is the use of resin fiber powder extracted from the circuit board without breaking the law?

- The general concept of glass is hard and brittle objects, not suitable as structural material, but as the thread, the strength is greatly increased and is flexible, with resin to give it shape can finally become excellent timber structure. Glass fibers increase in strength as their diameter decreases. As reinforcing materials, glass fiber has the following characteristics, which make glass fiber use much wider than other kinds of fiber

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High sound absorption material rock wool blanket with wire mesh Water repellent,asbestos fre

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords