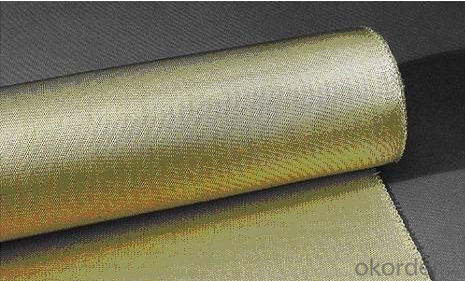

High Silica Texturized Tape with Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Our Silica Fibre fire Sleeve is an extreme high temperature, heat and flame resistant silica tape, and is an excellent alternative to asbestos and ceramic based textiles. The Silica Fibre Sleeve are primarily used as the thermal protection of circular items, the sleeves can be applied in aerospace (gas turbin and rocket engines), metallurgical, nuclear power, electricity generation, petrochemical industries, etc. for example, tube seals, high temperature gaskets, heaters,reformers,turbine exhaust,boilers, thermocouple wire,etc.

Applifications:

High silica texturized tapes can be used for a long period of time without changing its properties at the temperature of 1000℃,as it contains more than 96% silica.The performance of thermal insulation is excellent because of its texturized structure..

Application:Industrial wires,cables and pipes as thermal insulation material,heat gasket and seal material.

Specification:

| Product Code | SiO2 % | Working Temperature ℃ | Width mm | Thickness | Packing M/Roll |

| TSIP-32-0.8 | ≥94% | 1000 | 32-100 | 0.8 | 10,15,20 |

| TSIP-32-1.0 | ≥94% | 1000 | 32-100 | 1 | 10,15,20 |

| TSIP-32-1.5 | ≥94% | 1000 | 32-100 | 1.5 | 10,15 |

| TSIP-32-2.0 | ≥94% | 1000 | 32-100 | 2 | 10,15 |

| TSIP-32-2.5 | ≥94% | 1000 | 32-100 | 2.5 | 10,15 |

Package and delivery time

Package:Each roll in a polybag,then several rolls in one standard export carton box.

Delivery time:Within 7-15days

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q:What are the high temperature resistant fiberglass fabrics made in China?

- Before, domestic and foreign countries have a big gap. Later, with the upgrading of domestic technology, some large glass fiber enterprise production products and foreign countries have been comparable.

- Q:Are fiberglass fabrics resistant to chemicals?

- Fiberglass fabrics are known for their general resistance to chemicals. They are composed of fine glass fibers woven together to create a fabric. These fibers exhibit exceptional resistance to a wide range of chemicals, including acids, bases, solvents, and oils. As a result, fiberglass fabrics are well-suited for applications in industries such as industrial equipment, chemical processing plants, and automotive parts, where exposure to chemicals is common. However, it should be noted that the level of chemical resistance may vary depending on the specific type of fiberglass fabric and the concentration and duration of exposure to the chemicals. Consequently, it is always recommended to consult the manufacturer or supplier for precise information regarding the chemical compatibility and resistance of fiberglass fabrics.

- Q:Can fiberglass fabric be used for clothing?

- Yes, fiberglass fabric can be used for clothing. However, it is not commonly used for this purpose due to its abrasive and rigid nature, which can cause discomfort and potential skin irritation. Additionally, fiberglass fabric does not provide adequate breathability or flexibility required for comfortable clothing.

- Q:What are the different surface textures available in fiberglass fabric?

- Fiberglass fabric is known for its versatility and wide range of surface textures, each offering unique properties and benefits. Some of the different surface textures available in fiberglass fabric include: 1. Plain Weave: This is the most basic and commonly used texture, featuring a simple over-and-under pattern of fibers. It offers good strength and stability while providing a smooth surface finish. 2. Twill Weave: Twill weave consists of a diagonal pattern created by interlacing fibers. It offers improved drapability, better conformability, and increased strength compared to plain weave. Twill weave also provides a distinctive appearance. 3. Satin Weave: Satin weave involves floating yarns over multiple warp or weft yarns, resulting in a smooth and lustrous surface. It offers excellent flexibility, durability, and a high-quality finish. Satin weave is commonly used in applications requiring a high level of aesthetics. 4. Leno Weave: Leno weave is characterized by a pair of warp yarns twisting around weft yarns, creating an open mesh structure. This texture enhances breathability, allows easy resin saturation, and provides good drapability. Leno weave is often utilized in applications where air circulation or filtration is crucial. 5. Jacquard Weave: Jacquard weave involves complex patterns created by individual control of each warp yarn. It allows intricate designs and textures to be woven into the fabric. Jacquard weave is commonly used for decorative purposes or when specific patterns are required. Each surface texture in fiberglass fabric is designed to cater to specific applications, such as aerospace, automotive, marine, construction, and industrial sectors. The choice of texture depends on factors such as the desired strength, flexibility, aesthetics, and functionality required for the particular application.

- Q:Can fiberglass fabric be easily cut and sewn?

- Yes, fiberglass fabric can be easily cut and sewn. Due to its relatively lightweight and flexible nature, fiberglass fabric can be cut using regular scissors or a utility knife. However, it is important to wear protective gloves and a mask while cutting fiberglass fabric to avoid any irritation or inhalation of particles. When it comes to sewing, fiberglass fabric can be sewn using a regular sewing machine or by hand with a heavy-duty needle and strong thread. It is advisable to use a longer stitch length and to go slowly while sewing fiberglass fabric to prevent any damage to the fabric or the sewing machine. Overall, with the right precautions and tools, cutting and sewing fiberglass fabric can be done easily.

- Q:What is the typical width of fiberglass fabrics?

- The typical width of fiberglass fabrics can vary depending on the specific application and manufacturer. However, standard widths for fiberglass fabrics range from 36 to 60 inches (91-152 cm). These widths are commonly used in industries such as aerospace, automotive, construction, and marine. It is important to note that custom widths can also be produced for specific requirements if needed.

- Q:How does fiberglass fabric compare to other types of fabrics?

- Fiberglass fabric has several unique characteristics that set it apart from other types of fabrics. Firstly, fiberglass fabric is extremely strong and durable. It has a high tensile strength and can withstand heavy loads and stress without tearing or stretching. This makes it an ideal choice for applications where strength and durability are crucial, such as in industrial settings or for outdoor equipment. Secondly, fiberglass fabric is highly resistant to heat and fire. It has a high melting point and does not catch fire easily, making it a suitable choice for applications where fire safety is a concern, such as in insulation materials or protective clothing. Additionally, fiberglass fabric is resistant to chemicals and corrosion. It does not react with most chemicals, acids, or alkalis, making it suitable for use in environments where exposure to corrosive substances is common, such as in chemical plants or laboratories. Furthermore, fiberglass fabric is lightweight and flexible. Despite its strength, it is not bulky or heavy, making it easy to handle and work with. This flexibility also allows for its use in various applications where a certain level of flexibility is required, such as in the construction of curved surfaces or in the manufacturing of composite materials. However, there are some drawbacks to fiberglass fabric. It is not as comfortable or soft as other types of fabrics, which can make it less appealing for certain applications, such as in clothing or upholstery. Additionally, fiberglass fabric can be more expensive compared to some other types of fabrics. Overall, fiberglass fabric is a highly versatile material that offers exceptional strength, durability, heat resistance, chemical resistance, and flexibility. While it may not be suitable for all applications, it is an excellent choice for those requiring the unique properties it possesses.

- Q:How is fiberglass fabric tested for quality assurance?

- To ensure the quality and performance of fiberglass fabric, rigorous testing is carried out using various methods during the quality assurance process. The tensile strength test is one of the primary tests conducted on fiberglass fabric. This test determines the fabric's ability to resist forces that attempt to pull it apart. Tensile testing machines apply controlled loads to the fabric until it breaks, allowing for the determination of its maximum tensile strength. This test is crucial for assessing the fabric's durability and suitability for applications that involve high stress or load-bearing requirements. Another important test is the tear strength test, which measures the fabric's resistance to tearing or propagating a tear. In this test, a sample of the fiberglass fabric is gradually torn apart by a constant force. The force required to tear the fabric provides insight into its toughness and ability to withstand tearing forces. This is particularly important in applications where the fabric may come into contact with sharp objects or abrasive conditions. Dimensional stability is also evaluated by subjecting the fiberglass fabric to extreme temperature variations and measuring its ability to maintain its shape and size. This test ensures that the fabric can withstand environmental conditions without shrinking or expanding. It is particularly crucial for applications that involve temperature fluctuations. In addition, fiberglass fabric undergoes tests to assess its resistance to chemicals, moisture, and UV radiation. Chemical resistance tests involve exposing the fabric to various chemicals and evaluating its reaction, ensuring its suitability for applications where it may encounter corrosive substances. Moisture resistance tests assess the fabric's ability to repel water and resist mold or mildew growth. UV resistance tests determine the fabric's ability to withstand prolonged exposure to sunlight without experiencing degradation or loss of mechanical properties. Furthermore, the flame resistance of fiberglass fabric is assessed through flame tests. These tests involve exposing the fabric to a controlled flame and measuring its ability to self-extinguish or resist burning. Flame-resistant fiberglass fabric is essential for applications where fire hazards are present, ensuring the safety of individuals and the protection of property. Overall, fiberglass fabric undergoes a comprehensive range of tests to ensure its quality and suitability for various applications. By evaluating properties such as tensile strength, tear strength, dimensional stability, chemical resistance, moisture resistance, UV resistance, and flame resistance, manufacturers can provide high-quality fiberglass fabric that meets the specific requirements of different industries and applications.

- Q:Can fiberglass fabric be used for reinforcement in chemical processing tanks?

- Yes, fiberglass fabric can be used for reinforcement in chemical processing tanks. Fiberglass is highly resistant to corrosion and can withstand a wide range of chemicals, making it an ideal material for reinforcing tanks in chemical processing industries. It is lightweight, durable, and has excellent mechanical properties, making it suitable for withstanding the harsh conditions of chemical processing.

- Q:Is fiberglass fabric resistant to chemical degradation?

- Fiberglass fabric is known for its excellent resistance to chemical degradation. Due to its composition of glass fibers, which are impervious to most chemicals, it is highly resistant to the effects of various corrosive substances. Fiberglass fabric can withstand exposure to acids, alkalis, solvents, oils, and other chemicals commonly found in industrial environments without significant degradation. This makes it a preferred choice for applications where chemical resistance is of utmost importance, such as in the manufacturing of chemical storage tanks, pipes, and linings. Additionally, fiberglass fabric's resistance to chemical degradation also contributes to its durability and longevity, making it a reliable material for a wide range of industrial and commercial applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Silica Texturized Tape with Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords