High silica fiberglass casting filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High silica fiberglass casting filter

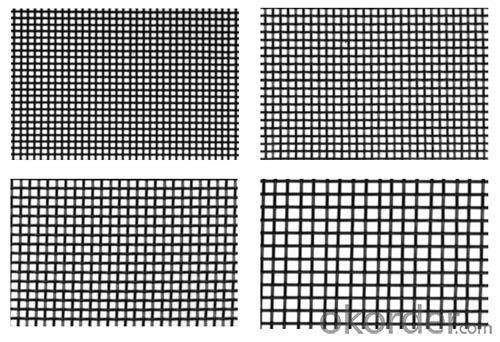

high silica mesh casting filter can effectively remove slag,refractory particles and non-metallic inclusions from molten metals.It is developed as a low cost but with rather filtration efficiency

alternative to ceramic filters.Made from specially treated silica yarns,silica mesh filters are capable of

withstanding pouring temperatures up to 1620 Degree C.Silica mesh filters are ideal for in-mold filtration of gray, malleable,white,compacted graphite and ductile cast irons, as well as non-ferrous

aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

ADVANTAGES:

• Low cost and easy to use

• Improves fluidity and metal distribution

• Removes micron sized inclusions and impurities

• Can be used with existing pattern equipment

• Eliminates inclusions created by ceramic chips

APPLICATIONS:

• Cut pieces for in mold filtration like sand casting,gravity casting,etc.

• Cut pieces for riser sleeves,bottom or across ports in walls

• Cut pieces to provide a weakened plane for riser knock-off

• Cup shapes for investment casting

SPECIFICATION:

Model No. | SiO2% | Thickness | Mesh size | Max.Temp. | Open area | Max.work time |

HSFG-15 | ≥96 | 0.35mm | 1.5x1.5mm | 1450℃ | 55% | 10minutes |

HSFG-20 | ≥96 | 0.35mm | 2.0x2.0mm | 1450℃ | 60% | 10minutes |

HSFG-25 | ≥96 | 0.35mm | 2.5x2.5mm | 1450℃ | 70% | 10minutes |

HSFG-S15 | ≥96 | 0.98mm | 1.5x1.5mm | 1620℃ | 22% | 15seconds |

HSFG-S20 | ≥96 | 0.98mm | 2.0x2.0mm | 1620℃ | 26% | 15seconds |

HSFG-S25 | ≥96 | 0.98mm | 2.5x2.5mm | 1620℃ | 32% | 15seconds |

FILTERING TIPS:

• Copper alloys&leaded bronze:1.5x1.5mm mesh

• Gray Iron:1.5x1.5mm mesh

• Ductile Iron:2.0x2.0mm &2.5x2.5mm mesh

• Small scale steel:1.5x1.5mm mesh

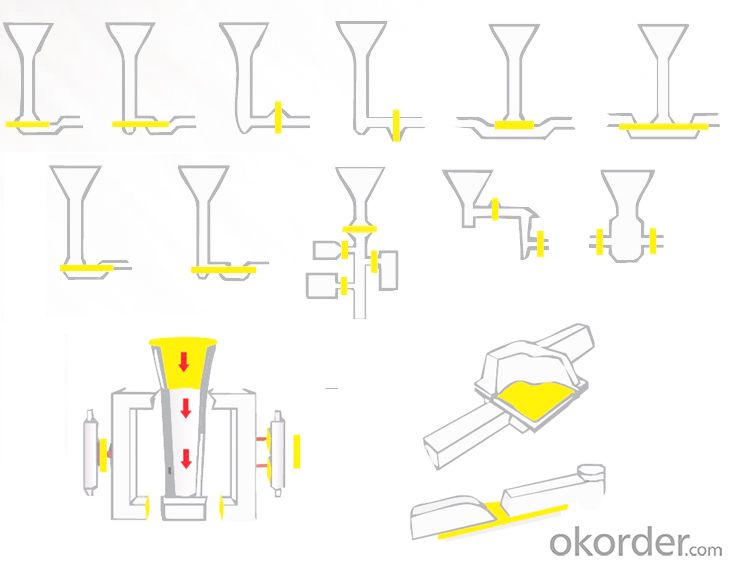

PLACEMENT POSITION:

*Cut pieces can be rectangular or round,size from 20mm to 900mm.

*Preformed cup filter OD can be 100/110/115/120mm or as per request.

- Q:What is the reason that the whole ceramic filter does not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q:Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- The shape and mechanism of the ceramic filter are similar to those of the disc vacuum filter, but the filter media are different. The filter medium of ceramic filter is the ceramic filter plate, it can produce the micro capillary effect and capillary force in micropores is higher than the general vacuum applied force, so that the pores keep full of liquid state, so no matter what the circumstances, the air does not pass through the ceramic filter plate, so that the ceramic filter solid-liquid separation of low energy consumption, and high vacuum.

- Q:The efficiency of ceramic filter is low. What's wrong with it?

- Ceramic filter by vacuum suction effect in the ceramic filter plate to cake drying purpose, ceramic filter plate needs cleaning and life, if you discover that the slurry sucking effect is poor or even grout should first consider these three aspects:Ceramic filter plateTwo factors of ceramic filter plate most likely, respectively is the rupture and plugging holes: the rupture will lead to distortion and poor vacuum cleaning; plugging holes will cause the filter plate suction effect is poor even if grout, ceramic filter plugging hole, can strengthen cleaning (such as shorten the cleaning cycle, prolong the cleaning time, increase the amount of nitrate), such as strengthening the cleaning effect is still not improved, it should consider the life approaching should be scrapped and replaced with ceramic filter plate new (replacement plate should not put new or different manufacturers is mounted on the same line, best can complete change).Vacuum system failureThe vacuum degree of ceramic filter is usually about -0.085MPa. If the abnormal vacuum is found, the normal vacuum suction can not be provided, and the suction effect will be poor, or even the pulp will not be sucked.If the vacuum is abnormal, should adhere to the vacuum pump, vacuum connection pipe is whether the fault Water Leakage leakage, distribution valve friction sealing, ceramic filter plate is connected with the rubber tube is aging or exfoliation, ceramic filter plate rupture.

- Q:What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q:What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

- Q:How much is the accuracy of 50nm ceramic membrane filtration?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q:What about the leakage of the ceramic filter static and dynamic sealing points?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

- Q:Why should filter core be used in backwash of ceramic filter?

- The filter in the water filter of ceramic filter is used for filtering water.

- Q:Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q:Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High silica fiberglass casting filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products