High QualitySolid Wood Moulding Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 meters m³

- Supply Capability:

- 500000 per month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Name:wood moulding

2.ISO/FSC certificate

3.Customized design

4.No warp in different temperature

5.Wood:alder, okume ,oak,sapele,cherry.

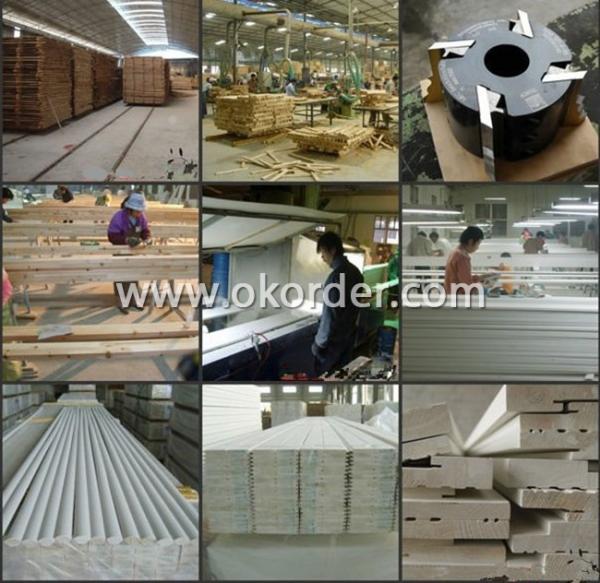

Manufacturing process of Solid Wood Moulding/Profile

1.Moulding preparation

The wood blanks are maufactured in mouling profiles.

2.Surface sand following moulding preparation, Machined(produced) with high speed planing equipment to yield a premium finish timber moulding ready for priming with a gesso coating.

3.Priming-stage:Mouldings are spray-coated with the 1st application of thin gesso coating.

4.Intermediate sanding stage:Surface sand following priming stage 1

5.Mouldings are spray-coated with the 2st(and final) application of water base primer.

6.Final product check with light sand and buff to the surface,that is readily painted with quality topcoats

Quality standards of Solid Moulding Profile

1.Moisture content must be accurately tested with an electronic moisture meter.

2.All dimensions should be within the dimensional tolerances as specified on the order

3.Coating application would be applied equally on all edges and has a strong adhesion to the wood substrate throug testing .No visible defects like

patching,open finger joints,bleed through,etc,after being coated/primed.

4. Mouldings would stay straight and not have excessive bow or spring.

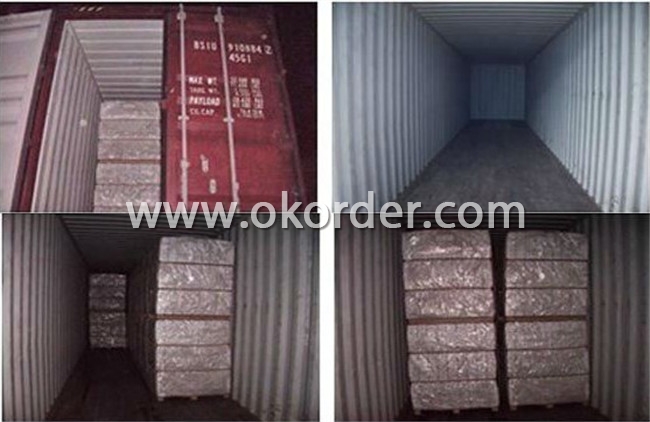

Packing&Loading

1.All mouldings to be packed in mini-bundles secured with tape, within the main pack structure.

2.Packs will be then strapped securely with poly strapping (to be confirmed by customer) to secure for shipment.

3.All bottom packs are secured to a plywood pallet that allows containerisation and unloading.

Species for Solid Wood Moulding/Profile

Production Progress for Solid Wood Moulding/Profile

Loading for Solid Wood Moulding/Profile

- Q:The difference between high density board and solid wood board

- It is made of wood fiber or other plant fiber as raw material, urea-formaldehyde resin or other suitable adhesive made of artificial plate, according to their density, divided into high density board

- Q:Solid wood board, solid wood particle board, MDB What is the difference between

- some Chlorophyta and other plants, also have a certain effect on the formaldehyde and

- Q:The use of solid wood panels

- The use of cheap, and easy to construction of man-made sheet metal decoration is a wise choice

- Q:Solid wood of the plate board of environmental protection

- At the same time with weak electricity, formaldehyde, ammonia, benzene, toluene, xylene molecular diameter are between 0.4-0.62 nm,

- Q:medium density board than the particle board grip nail difference

- In contrast, the clamping force of the MDF is worse than that of the board, and if the screw is tightened

- Q:The characteristics of wood-based panels and solid wood panels are as follows

- Particleboard commonly used in desktop, bed and a variety of board cabinet furniture. A variety of particleboard thickness of 13mm, 16mm, 19mm, 22mm.

- Q:What is solid wood board?

- Solid wood is made of complete wood (logs) made of wood. Solid wood board generally in accordance with the plate material (wood material) name classification

- Q:Anti-injury of solid wood board

- not to be placed directly on the wood surface to prevent operation. If operation, should be repaired at all times.

- Q:What are the characteristics of solid wood, what are their characteristics

- First, the classification of wood 1, according to the material classification can be divided into: solid wood, wood-based panels two categories

- Q:These plates are rugged, natural lines, is the best choice in the decoration.

- Solid wood panels are generally classified according to the physical name of the plate, there is no uniform standard specifications

1. Manufacturer Overview |

|

|---|---|

| Location | Fujian,China |

| Year Established | 1992 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | "Mid East;Eastern Europe;North America;China " |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Fuzhou;Fujian |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 51-60 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | 33000 square meters |

| No. of Production Lines | 6 lines |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

High QualitySolid Wood Moulding Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 meters m³

- Supply Capability:

- 500000 per month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords