High Quality Wood Engraving Machine CNC Router

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNC Router For Woodworking

1.1300 x 2500 x 200 mm

2.Air Cooled Spindle

3.CE Certificate & OEM supported

1.SPECIFICATION

WORKING AREA | 1300 X 2500 X 200mm |

SPINDLE POWER | 6KW,AIR COOLED,6000-24000RPM/MIN |

DRIVE SYSTEM | STEPPER MOTOR AND DRIVERS ON X,Y,Z AXIS |

WORKING SPEED | Y AXIS 25M/MIN, X AXIS 25M,Z AXIS 20M/MIN |

CONTROL SYSTEM | NC STUDIO NUMERICAL CNC SYSTEM (ENGLISH LANGUAGE);DSP PROGRAM |

WORKING VOLTAGE | 220V /380V |

TABLE | PVC MATERIAL WITH VACUUM SYSTEM |

OVERALL DIMENSION | 3900 X 2100 X 2100MM |

NET WEIGHT | 1200KGS |

2. DETAIL PARTS INTRODUCTION

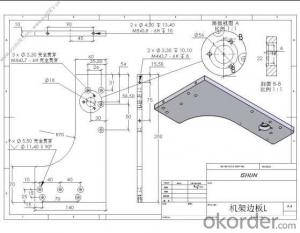

a). CONTROL CABINET BOARD

b). PRECISION RAIL GUIDE AND RACKS FOR TRANSMISSION (X&Y AXIS TRANSMISSION)

c). CONTROL CABINET d).OIL PUMPS FOR LUBRICATION

e). LEAD BALL SCRE (Z AXIS TRANSMISSION)

3. OTHER TERMS FOR MACHINERY

SINGLE PACKAGE: WOOD PALLET OR WOODEN CASE (OPTIONAL)

DELIVERY TIME: AFTER CONFIRMATION THE ORDER 35 DAYS

LOADING PORT: QINGDAO PORT, SHANDONG PROVINCE

- Q:CNC woodworking engraving machine can be processed?

- CNC woodworking engraving machine can process all kinds of wood, wood, wood pieces, that is, a variety of wood, wood, wood molding.

- Q:How should the engraving machine adjust the diagonal line?

- Customer service technician general non professional personnel or some engraving machine manufacturers are not adjusted, the release gear box to push the motor way, this way can temporarily solve the problem is to deceive customers maintenance personnel.

- Q:Woodworking engraving machine work, the main axis of the continuous downward, what is the reason?

- Hardware: motor failure, transmission parts loose, bearing problems; electrical components: drives, control cards, wires and so on, need to pay attention to exclude.

- Q:What is the difference between the servo system and the stepping system of woodworking engraving machine?

- Stepper motor is a discrete motion device, and it has an essential connection with modern digital control technology. In the domestic digital control system, the application of stepping motor is very extensive.

- Q:Who knows extension carving multi head rotary woodworking engraving machine graphics what software is used?

- Drawing are carved, the Thai 2 commonly used software, no matter what you use engraving machine, are the 2 commonly used to map, of course, can be carved out of the preview effect

- Q:What software is commonly used in woodworking engraving machines?

- The control software is more weihong. Software also has useful carved thai.

- Q:How long can the life of a woodworking engraving machine last? If the maintenance is good!

- And the amount of processing is very large, long-term work. Of course, careful maintenance is a prerequisite.

- Q:325 woodworking engraving machine, engraving 50mm thick MDF, need how much of the spindle, the Z axis travel what are the requirements? What knife do you need?

- Double edge straight groove knife, without slicing, ordinary density board single line cutting, then a knife can go down, I have not seen 50 mm, it is necessary to layered.

- Q:Large automatic CNC woodworking engraving machine, the general configuration of the current how much money?

- There are different configurations, spindle, drive, precision, and operating system, etc.;In addition, apart from the standard configuration, you need to add other accessories.

- Q:How should the cutters of the engraving machine be distinguished?

- The selection of tool materials and high precision grinding process is generally not more than the tool, the tool precision is within 0.02MM, the angle error within 0.05 degrees, which can guarantee the high quality of products, and can achieve high efficiency is to choose this tool.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Wood Engraving Machine CNC Router

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords