High Quality Structural Steel H-Beam for Construction, Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

Specifications of High Quality Structural Steel H-Beam for Construction

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

Usage & Applications ofHigh Quality Structural Steel H-Beam for Construction

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of High Quality Structural Steel H-Beam for Construction

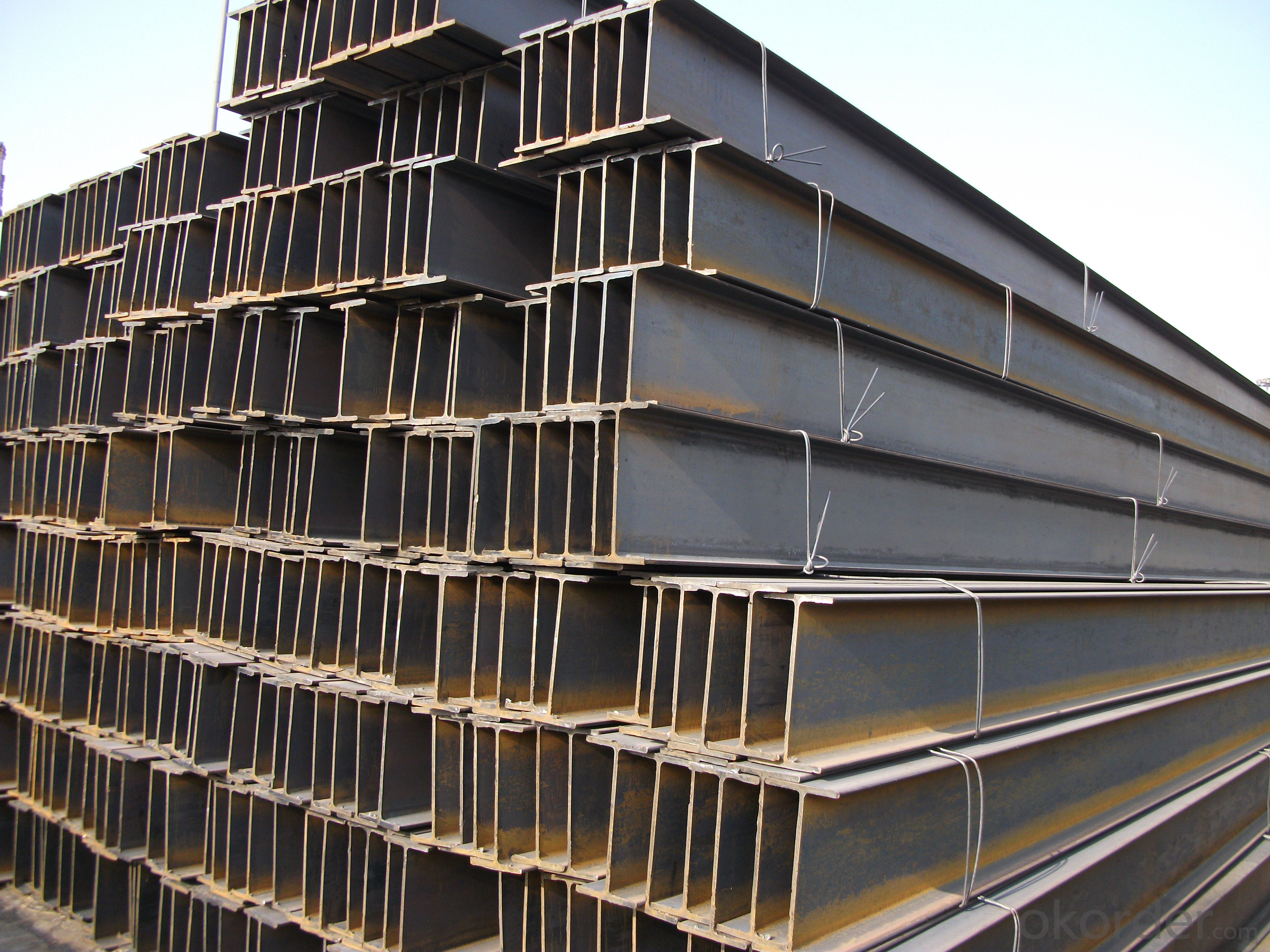

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of High Quality Structural Steel H-Beam for Construction

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Images

- Q:Can Steel H-Beams be used in agricultural or industrial buildings?

- Steel H-Beams have a wide range of applications in agricultural and industrial buildings. Their strength and durability make them a common choice in construction. They offer structural support and can handle heavy loads, making them suitable for various purposes. In agricultural buildings, Steel H-Beams can be utilized to provide a strong framework for the structure and support the roof. They can also be used as columns or beams to create open spaces or support mezzanine floors. Similarly, in industrial buildings, Steel H-Beams are frequently employed for the same reasons, providing stability and versatility for large-scale operations. Furthermore, Steel H-Beams can be easily customized and fabricated to meet specific design requirements, which contributes to their popularity in both agricultural and industrial construction projects.

- Q:Can steel H-beams be used in mezzanine floor construction?

- Indeed, it is possible to employ steel H-beams in the construction of mezzanine floors. These H-beams, alternatively referred to as I-beams or universal beams, are frequently utilized in the field of construction owing to their impressive strength and ability to bear heavy loads. Mezzanine floors, which serve as intermediate levels between a building's primary floors, often necessitate the use of steel beams to support the added weight and ensure structural stability. Opting for steel H-beams in mezzanine floor construction is a highly recommended choice due to their capacity to endure substantial loads and provide enduring durability.

- Q:What is the theoretical weight of welded H - section steel 900*350*20*30?

- H steel is mainly used in engineering, plant, equipment, machinery and equipment, bridges, highways, houses, etc., with good mechanical and physical properties, firm and energy-saving and environmental protection. H steel is an economical section steel, widely used in industry, construction, bridge, oil drilling and so on

- Q:What are the thermal conductivity properties of steel H-beams?

- Steel H-beams exhibit a relatively high level of thermal conductivity. Thermal conductivity refers to a material's capacity to transfer heat. Compared to materials like wood or plastics, steel demonstrates superior thermal conductivity due to its ability to conduct heat effectively. The precise thermal conductivity of steel H-beams may differ depending on the specific alloy and composition of the steel utilized. Nevertheless, on average, steel exhibits a thermal conductivity range of 15 to 50 W/m·K (watts per meter kelvin). Consequently, steel H-beams excel in facilitating heat transfer and are capable of rapidly distributing thermal energy throughout their structure. The exceptional thermal conductivity of steel H-beams renders them suitable for diverse applications within the fields of construction and engineering. For instance, when employed in buildings, steel H-beams can aid in the dissipation of heat and the prevention of hot spots. Moreover, they can be utilized in heat transfer systems such as heat exchangers, where efficient heat transfer is paramount. In summary, steel H-beams possess commendable thermal conductivity properties, enabling them to conduct and distribute heat efficiently.

- Q:What are the materials of H steel?

- The necessary grades can be marked behind said deoxidation methods of quality grades and symbols. The quality class symbols are A, B, C, and D respectively. Deoxidation method notation: F means boiling steel; B represents semi killed steel: Z indicates calm steel; TZ stands for special sedation steel; calm steel is not marked; Z and TZ are not standard. For example, Q235-AF indicates a class of rimmed steel.

- Q:Are steel H-beams suitable for use in high-rise buildings?

- Yes, steel H-beams are suitable for use in high-rise buildings. They provide excellent structural support, allowing for the construction of tall and sturdy buildings. The H-shape design of these beams offers superior strength and load-bearing capacity, making them an ideal choice for handling the vertical and horizontal forces experienced in high-rise structures.

- Q:What are the considerations when transporting or handling Steel H-Beams?

- When transporting or handling Steel H-Beams, there are several key considerations to keep in mind. Firstly, it is important to ensure the beams are securely fastened and properly balanced during transportation to prevent any shifting or tipping. Additionally, the beams should be protected against damage from impacts, vibrations, and adverse weather conditions by using appropriate packaging or covering them with suitable materials. It is crucial to use the correct lifting equipment and techniques to avoid overloading or damaging the H-Beams. Furthermore, the personnel involved in the transportation and handling process should be adequately trained and equipped with personal protective equipment to ensure their safety. Regular inspections and maintenance of the equipment used for transportation are also necessary to minimize any potential risks and ensure the integrity of the H-Beams.

- Q:What are the different types of steel H-beam connections used in retail buildings?

- In retail buildings, various types of steel H-beam connections are used to ensure structural integrity and stability. Some of the commonly used connections are: 1. Welded Connection: This is the most commonly used connection in retail buildings. It involves welding the flange of one H-beam to the web of another H-beam, creating a strong bond. Welded connections are known for their high strength and durability. 2. Bolted Connection: Bolted connections involve using bolts and nuts to connect the flanges of two H-beams together. This type of connection offers flexibility as it allows for easy disassembly and reassembly if required. Bolted connections are also cost-effective and can be used in areas where welding is not preferred. 3. Gusset Plate Connection: In this type of connection, a gusset plate is used to connect the flanges of two H-beams. The gusset plate is typically made of steel and is bolted or welded to the flanges. This connection adds extra strength and stability to the structure. 4. Moment Connection: Moment connections are used in areas where high bending moments are expected. These connections provide rotational stiffness and transfer moments from one H-beam to another, ensuring the overall stability of the structure. 5. Shear Connection: Shear connections are used to transfer shear forces between H-beams. These connections involve using bolts or welds to join the webs of two H-beams together. Shear connections are essential for ensuring the overall stability and load-bearing capacity of the structure. 6. Bracing Connection: Bracing connections are used to provide additional lateral support to the structure. They involve connecting diagonal braces to the H-beams using bolts or welds. Bracing connections help resist lateral forces such as wind or seismic loads, enhancing the overall stability and safety of the retail building. It is important to consult with structural engineers and adhere to local building codes and regulations when selecting and designing H-beam connections for retail buildings. The type of connection used will depend on factors such as the structural requirements, architectural design, and the specific loads acting on the structure.

- Q:What is the load-bearing capacity of H steel spans 6 meters and 300 * 300? How is it calculated?

- Unable to bear too much weight. It is recommended to use more than 600*300*12*18 H steel.

- Q:How do steel H-beams contribute to sustainable infrastructure?

- There are several ways in which steel H-beams contribute to sustainable infrastructure. To begin with, steel is a highly recyclable material. This means that H-beams can be made from recycled steel, reducing the need for new raw materials and the environmental impact of mining and extraction. Additionally, steel is a durable material, which means that H-beams have a long lifespan and require minimal maintenance or replacement. This reduces the need for frequent material replacement and the waste generated from construction and demolition activities. Moreover, steel H-beams are both lightweight and strong. This allows for more efficient transportation and installation, resulting in reduced energy consumption and greenhouse gas emissions. The lightweight nature of steel H-beams also enables more flexibility in design and construction, allowing for innovative and sustainable architectural solutions. Furthermore, steel H-beams are highly resistant to environmental factors such as corrosion, fire, and seismic activity. This ensures the longevity and safety of infrastructure projects, reducing the need for frequent repairs or reconstruction. Additionally, their strength and load-bearing capacity make them ideal for constructing sustainable structures, such as bridges and high-rise buildings, which can accommodate a larger number of occupants and reduce the need for sprawling urban development. Lastly, steel H-beams are compatible with modern construction techniques, such as modular construction and prefabrication. These methods enable faster construction times, reduced waste, and minimized disruption to the surrounding environment. By using steel H-beams in these construction techniques, we promote sustainable practices and meet the increasing demand for infrastructure more efficiently and in an environmentally friendly manner. In conclusion, steel H-beams contribute to sustainable infrastructure through their recyclability, durability, lightweight design, resistance to environmental factors, compatibility with modern construction techniques, and their ability to facilitate innovative architectural solutions. By incorporating steel H-beams into infrastructure projects, we can reduce environmental impact, enhance the longevity and safety of structures, and promote more sustainable urban development.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Structural Steel H-Beam for Construction, Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords