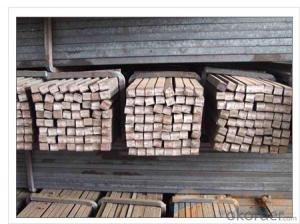

High Quality Steel Square Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

square steel billet

1.3SP, 5SP

2.terms of payment: L/C at sight

3.size: 120*120mm

4.length: 5.8~12m

square steel billet

Specifications

square steel billets

1)We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

M.S. Billets

CRS Billets

Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

The following are the sizes of Billets available with Shyam Steel Industries Ltd.:

100 X 100

120x120

150 X 150

Physical Properties:

Description

As per IS 2830

Shyam Billets

Bend (max.) 5 mm per meter >= 5 mm per meter

Carbon (max.) 3mm per meter >= 3 mm per meter

Length 3 mt - 13 mt 3 mt - 9 mt

Chemical Properties:

Ladle Analysis:

Designation

Carbon

Manganese

C15 0.12-0.18 0.30-0.60

C18 0.15-0.21 0.30-0.60

C20 0.17-0.23 0.30-0.60

C15 MMn 0.12-0.18 0.60-1.00

C18 MMn 0.15-0.21 0.60-1.00

C20 MMn 0.17-0.23 0.60-1.00

C15 HMn 0.12-0.18 1.00-1.50

C18 HMn 0.15-0.21 1.00-1.50

C20 HMn

0.17-0.23 1.00-1.50

Billets of different designations are manufactured in three different grades namely A, B, C having sulphur, phosphorous content (on ladle analysis) and carbon equivalent as follows:

Chemical Analysis:

Grade Sulphur Phosphorous Carbon Equivalent (CE)1

Max Max Max

A 0.05 0.05 0.42

B 0.045 0.045 0.41

C 0.04 0.04 0.39

- Q:Can a steel square be used for checking the alignment of machinery?

- Yes, a steel square can be used for checking the alignment of machinery. A steel square is a versatile tool that is commonly used in carpentry and metalworking for measuring right angles and checking the alignment of various components. It consists of a long metal blade and a shorter metal tongue that meet at a 90-degree angle. To check the alignment of machinery, a steel square can be placed against different parts of the machine to determine if they are perpendicular or parallel. For example, it can be used to check if the table of a milling machine is square to the spindle, or if a drill press table is parallel to the drill bit. By placing the square against different surfaces, it can provide a visual indication if the alignment is off or needs adjustment. However, it is important to note that while a steel square can be a useful tool for initial alignment checks, it may not provide the level of precision required for highly accurate machinery alignment. In such cases, specialized alignment tools such as dial indicators or laser alignment systems may be necessary. Additionally, it is always recommended to consult the manufacturer's guidelines or seek professional assistance for proper machinery alignment procedures.

- Q:Can a steel square be used for roofing work?

- Yes, a steel square can be used for roofing work. It is a versatile tool that can be used for measuring and marking angles, determining pitch, and making accurate cuts. Its sturdy construction and durability make it suitable for various roofing tasks.

- Q:How do you use a steel square to determine the slope of a staircase?

- In order to determine the slope of a staircase using a steel square, one must first have an understanding of the fundamental layout and structure of the staircase. To initiate the process, position the steel square at the bottom of the staircase, ensuring that one arm (blade) is resting against the vertical face of the initial step. Achieve perfect levelness of the square by making adjustments until the bubble in the level is centered. Following this, tilt the square so that the blade becomes parallel to the incline of the staircase. Consequently, the blade should make contact with the nosing, which is the overhanging edge of the step. Make note of the number or measurement displayed on the scale of the steel square at the point where the tongue (the shorter arm) intersects with the tread (the horizontal surface of the step). This measurement indicates the rise of the staircase. In a similar manner, relocate the steel square to the next step, aligning the blade with the vertical face and tilting it parallel to the incline. Once again, observe the measurement where the tongue meets the tread, which represents the rise of the second step. Repeat this procedure for each step, documenting the rise for every individual step to ascertain the overall slope of the staircase. To calculate the slope, divide the total rise of the staircase by the total run, which refers to the horizontal distance covered by the staircase. The resulting ratio will determine the slope of the staircase. It is essential to note that using a steel square as a means to determine the slope of a staircase is a rudimentary method and may not yield the most accurate measurement. For more precise calculations, it is advisable to employ specialized tools or seek guidance from professionals in the field.

- Q:How do you use a steel square to determine the angle of a roof pitch?

- In order to determine the angle of a roof pitch using a steel square, a few simple steps must be followed. Begin by placing the steel square on the roof in a manner where one leg aligns with the horizontal edge of the roof. Make sure that the long edge of the square extends over the slope of the roof. Then, locate the notch on the square that corresponds to the desired angle of the roof pitch. This particular notch is often labeled with the degree of the angle it represents. After identifying the correct notch, pivot the square until the other leg aligns with the roof pitch. It is crucial to securely hold the square against the roof surface to ensure accurate results. Lastly, read the degree or angle value indicated on the square at the intersection of the two legs. This measurement signifies the angle of the roof pitch. By adhering to these steps and utilizing a steel square properly, one can determine the angle of a roof pitch with precision and efficiency.

- Q:Can a steel square be used for checking the alignment of a roof frame?

- Yes, a steel square can be used for checking the alignment of a roof frame. A steel square, also known as a carpenter's square or framing square, is a versatile and essential tool in construction and carpentry. It consists of a long arm and a shorter, perpendicular arm that meet at a right angle. To check the alignment of a roof frame, the steel square can be used to ensure that the angles are square and that the frame is level and plumb. The long arm of the square can be used to measure and mark the angles of the roof frame, while the shorter arm can be used to check for squareness and alignment. By placing the steel square against the roof frame's joints or corners, one can visually assess if they align with the right angle of the square. If the frame is properly aligned, the square will fit snugly against the joints or corners. If there is any deviation or misalignment, adjustments can be made accordingly. Additionally, the steel square can be used as a guide to mark and cut rafters or other roof frame components accurately. Its straight edges and right angles provide a reliable reference for ensuring the proper alignment and fit of these components. In summary, a steel square is an effective tool for checking the alignment of a roof frame. It helps ensure that the frame is square, level, and plumb, providing a solid foundation for the rest of the roof construction process.

- Q:Can a steel square be used for wainscoting installation?

- Yes, a steel square can be used for wainscoting installation. A steel square is a versatile and durable tool that is commonly used in carpentry and woodworking projects. Its primary purpose is to assist in measuring and marking right angles and ensuring accurate cuts and joinery. When installing wainscoting, a steel square can be used to mark and measure the height and width of the panels, as well as to ensure proper alignment and levelness during installation. It can also be used to check for squareness and make precise cuts when trimming the panels to fit around corners or obstacles. Overall, a steel square can be a valuable tool for achieving precise and professional-looking wainscoting installation.

- Q:Can a steel square be used for checking the squareness of door frames?

- Yes, a steel square can be used for checking the squareness of door frames. A steel square, also known as a framing square, is a tool commonly used in carpentry and woodworking to ensure the accuracy and squareness of various angles and joints. It consists of two arms, typically made of steel, forming a right angle. One arm is longer and is called the blade, while the other arm is shorter and is called the tongue. To check the squareness of a door frame using a steel square, you can place the longer blade against the inside corner of the frame where the door will be installed. Then, extend the shorter tongue along the inside edge of the door frame. By visually inspecting the alignment of the door frame with the steel square, you can determine if it is perfectly square or if adjustments are needed. If the door frame is not square, it can cause problems during the installation of the door, such as difficulty in opening and closing, gaps between the door and the frame, or uneven wear on the door over time. By using a steel square, you can ensure that the door frame is properly aligned and square before installing the door, resulting in a smooth and functional operation.

- Q:Can a steel square be used for flooring installation?

- No, a steel square is not typically used for flooring installation. Flooring installation requires specialized tools and materials such as adhesive, underlayment, and flooring nails or staples. A steel square is more commonly used in carpentry for measuring and marking angles, not for the actual installation of flooring.

- Q:How do you use a steel square to measure and mark obtuse angles?

- To measure and mark obtuse angles using a steel square, you need to follow these steps: 1. Place the long edge of the steel square against one side of the angle you want to measure. 2. Align the short edge of the square with the other side of the angle. 3. Observe the scale or markings on the square's blade to determine the angle's measurement. 4. Use a pencil or marker to mark the angle's measurement on the material or surface you're working on. Remember that a steel square typically measures up to 90 degrees, so if the angle you're measuring is greater than 90 degrees, you'll need to calculate the difference and mark it accordingly.

- Q:Can a steel square be used for checking the squareness of a jointer knife?

- Using a steel square to check the squareness of a jointer knife is not possible. Although a steel square is commonly employed to assess the squareness of woodworking tools and machinery, it is not appropriate for this particular undertaking. Jointer knives necessitate the use of a specialized tool, such as a jointer knife gauge or a magnetic jointer knife setting gauge, which is specifically designed to accurately measure the squareness of the knife. These gauges typically feature a magnet that can be attached to the knife, enabling precise and dependable measurements. Utilizing a steel square for this purpose may yield inaccurate readings and potentially compromise the jointer's performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Steel Square Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords