high quality steel light rail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

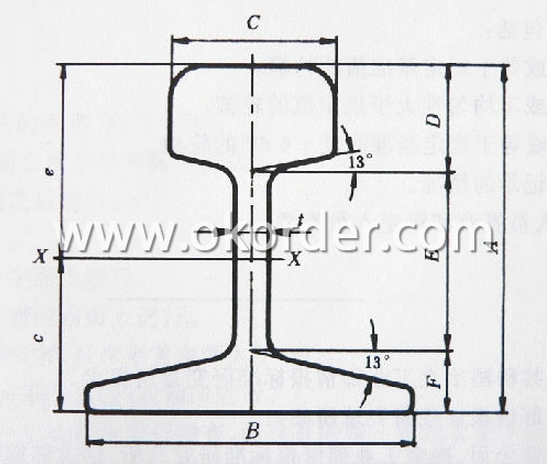

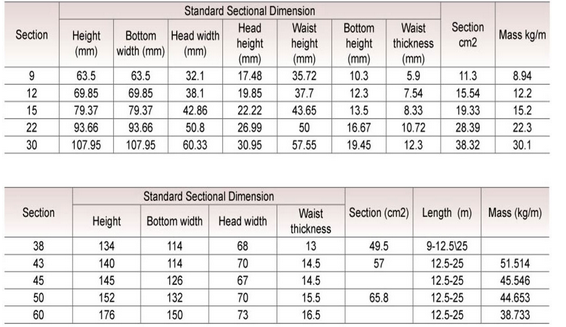

Specifications of Ms Steel Rail

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: 55Q

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Ms Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Ms Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Ms Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:How do steel rails handle temperature variations?

- Steel rails handle temperature variations by expanding and contracting. When the temperature increases, the rails expand, and when the temperature decreases, they contract. This expansion and contraction are accommodated by leaving small gaps between the rail segments. Additionally, steel rails are designed to have a certain degree of flexibility, allowing them to adjust to temperature changes without causing significant damage or distortion.

- Q:Are steel rails compatible with different train types?

- Yes, steel rails are compatible with different train types. Steel rails provide a stable and durable track structure that can accommodate a wide range of train sizes and weights. They are designed to withstand the forces generated by different train types, including heavy freight trains and high-speed passenger trains. The standardized dimensions and specifications of steel rails ensure compatibility across various train types, allowing for efficient and safe railway operations.

- Q:How do steel rails handle changes in track gauge?

- Steel rails are designed to handle changes in track gauge by being flexible and durable. They provide stability and support to the train, allowing it to smoothly transition from one gauge to another without causing any disruptions or derailments. This is achieved through careful engineering and design, ensuring that the rails can accommodate variations in gauge while maintaining their structural integrity.

- Q:How are steel rails used in railway electrification systems?

- Railway electrification systems rely heavily on steel rails, which act as the primary conductors of electrical current. Their purpose is to facilitate the efficient transfer of power from the power supply to the trains. In this configuration, the steel rails function as the positive conductor, delivering direct current (DC) to power the electric locomotives and trains. To ensure uninterrupted power supply, the rails are installed in a continuous track layout throughout the railway network. To optimize electrical conductivity, the steel rails are crafted from high-quality steel that possesses excellent electrical conductivity properties. Additionally, precision manufacturing guarantees uniformity and consistency in electrical resistance across the entire railway network. The electrification system operates on the basis of a pantograph, which is affixed to the train's roof and serves to collect electricity from overhead lines or catenary wires. As the train progresses along the tracks, the pantograph maintains contact with the overhead lines, allowing the flow of electrical current from the wires to the steel rails. Beyond their role as conductors, steel rails also provide mechanical support to the trains. They guide the wheels along the track, ensuring smooth movement, and evenly distribute the weight of the train. This combination of electrical conductivity and mechanical stability makes steel rails an integral component of railway electrification systems. Overall, steel rails are indispensable in railway electrification systems, as they establish a dependable pathway for the flow of electricity and enable the efficient transfer of power to the trains. Their design ensures both electrical conductivity and mechanical stability, making them vital to the smooth and reliable operation of electric trains in modern railway networks.

- Q:How do steel rails contribute to the overall safety of train operations?

- Steel rails contribute to the overall safety of train operations in several ways. Firstly, steel rails provide a sturdy and stable track structure that allows trains to run smoothly and safely. They ensure that the wheels of the train have a consistent and reliable surface to travel on, reducing the risk of derailment or accidents caused by track instability. Additionally, steel rails are designed to withstand heavy loads and extreme weather conditions, providing durability and resilience to the track. This minimizes the chances of track failures or damage, which could otherwise pose a significant risk to train operations and passengers' safety. Moreover, steel rails are highly resistant to wear and tear, reducing the need for frequent maintenance and repairs. This helps to ensure that the track remains in good condition, further enhancing the safety of train operations. Overall, the use of steel rails in train operations plays a crucial role in maintaining a safe and reliable transportation system, minimizing the risk of accidents and ensuring the well-being of passengers and crew.

- Q:How are steel rails protected against electrical discharge?

- Steel rails are typically protected against electrical discharge through the use of insulating materials, such as rubber or plastic coatings, which prevent direct contact between the rails and surrounding electrical sources. Additionally, periodic maintenance and inspections are carried out to ensure the integrity of the insulation and promptly address any potential issues.

- Q:What is the impact of curved tracks on steel rail performance?

- Curved tracks have a significant impact on the performance of steel rails. The curvature introduces lateral forces and increases the wear and tear on the rails, leading to higher maintenance and replacement costs. Additionally, the lateral forces can cause rail distortion and increase the risk of derailment. Therefore, proper design and maintenance of curved tracks are crucial to ensure optimal performance and safety of steel rails.

- Q:Can steel rails be used in high-speed train systems?

- Yes, steel rails can be used in high-speed train systems. Steel rails are commonly used in high-speed train tracks due to their durability, strength, and ability to handle heavy loads. They provide a stable and reliable track foundation, ensuring smooth and safe travel at high speeds.

- Q:What is the impact of steel rails on train braking distance?

- The impact of steel rails on train braking distance is significant. Steel rails provide a smooth and durable surface for trains to travel on, but they also affect the braking performance of trains. Steel rails have a high coefficient of friction, which means that they provide excellent traction for train wheels. This allows trains to brake effectively and come to a stop within a reasonable distance. The friction between the steel rails and the train wheels helps in slowing down the train and controlling its speed during braking. Furthermore, steel rails are designed to withstand the weight and forces exerted by trains. They are built to be sturdy and durable, ensuring that they can handle the immense pressure exerted on them during braking. This gives the train wheels a reliable surface to grip onto, enhancing the braking efficiency. However, there are certain factors that can affect the impact of steel rails on train braking distance. For instance, the condition of the steel rails plays a crucial role. If the rails are worn out, damaged, or contaminated with debris, it can reduce the traction between the wheels and rails, leading to longer braking distances. Additionally, weather conditions can also influence braking distance on steel rails. Wet or icy rails can reduce the friction between the wheels and rails, making it more challenging for trains to brake effectively. This is why special measures, such as applying sand or anti-icing agents, are taken in such conditions to improve traction and reduce braking distances. In conclusion, steel rails have a significant impact on train braking distance. They provide the necessary traction and durability for trains to brake effectively. However, factors like rail condition and weather conditions can influence braking performance. Regular maintenance and appropriate measures during adverse weather conditions are essential to ensure safe and efficient train braking.

- Q:Are steel rails susceptible to corrosion?

- Yes, steel rails are susceptible to corrosion. Over time, exposure to moisture, oxygen, and other environmental factors can cause steel rails to rust and deteriorate, compromising their structural integrity and performance. Regular maintenance and protective coatings are typically required to prevent or mitigate corrosion on steel rails.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high quality steel light rail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords