High Quality SK34 Fireclay Brick for Industry Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High alumina fireclay Brick

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Fireclay brick is shaped refractory product.It is made from flint clay clinker and binder , Through high heat sintering. The Al2O3 content range from 28% to 48%.The refractoriness range from 1580°C to 1750°C(SK-30.SK-32.SK-34.SK-35).

Product Applications:

High alumina fireclay Brick are ideal for use in the below applications

Furnaces of metallurgy industry, heat treatment furnace

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace

Standard sizing: 230 x 114 x 65 mm others up to the client

Product Advantages:

CNBM has success in its Fireclay brick due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

High refractoriness,High-temperature endurable .

Good corrosion resistance.

Good spalling resistance and wear resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

Good volume stability at high temperature.

Product Specifications:

ITEM | UNF42 | UNF46 | ZGN42 | RN40 | TDL45-12 |

Refractoriness, ℃ | 1730 | 1750 | 1750 | 1730 | 1760 |

Bulk Density, g/cm3 | 2.15 | 2.25 | 2.3 | 2.15 | 2.37 |

Apparent Porosity, % | 22 | 20 | 15 | 24 | 12 |

C.C.S, Mpa | 30 | 35 | 58 | 28 | 68 |

Refractories Under Load (0.2Mpa),℃ | 1400 | 1420 | 1450 | 1430 | 1500 |

Reheating Linear Change, % | 1400℃x2h 0.1~-0.4 | 1430℃x2h 0~-0.1 | 1450℃x2h 0~-0.2 | 1350℃x2h 0~-0.3 | 1450℃x2h -0.1~+0.05 |

Al2O3 Content , % | 42 | 46 | 42 | 40 | 45 |

Size :

Common sizes

Straight type | Arch type | Wedge type |

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

Other sizes according to customer requirements | ||

FAQ:

Q1: How about your factory’s annual production capacity?

A1:CMAX annual production is about 310,000Tons.

Q2: How many production lines of your factory?

A2:CMAX has 26 production lines, including eight silicon bricks lines, and each one of mullite brick, high alumina brick, insulating brick and monolithics line.

Q3:How large the scale of your factory?

A3: CMAX covers almost 200,000 Square meters, including plant area of 180,000 square meters.

Q4: What’s your factory’s product scope?

A4:CMAX main products are: refractory for hot blast stove, refractory for coke oven, refractory for glass kiln, refractory for carbon calcining furnace, refractory for acid pickling line, refractory for cement kiln, refractory for blast furnace, refractory for nonferrous metal furnace, and basic refractory raw materials.

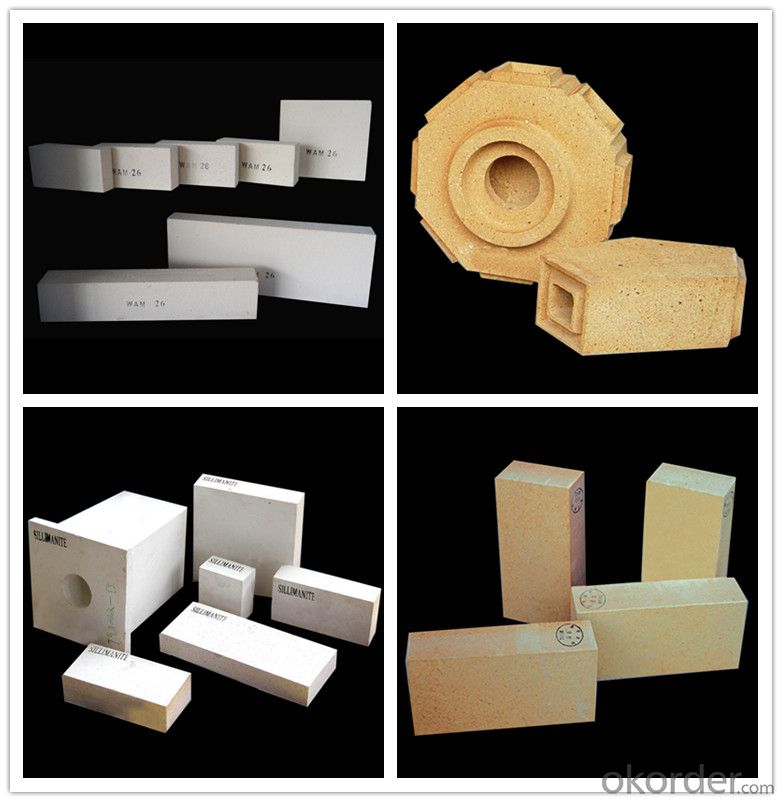

Product Picture

Produce Processing

Crushing

In this stage massive raw materials which have been stored, are ground and classified into proper sizes, making them easier to shape.

Mixing

The prescribed size of ground raw material is weighed and mixed into a designated amount of water and forming agent.

Shaping

The mixture is then poured into a mold to form shapes, and the pressure is high.

Drying

In this stage water is removed from the shaped bricks. This helps preventing the bricks from deforming or cracking which may result due to the rapid evaporation

Firing

This is the most crucial process in refractory manufacturing. The modeled bricks are fired at high temperature to complete their thermochemical reaction so that they do not deform.

Inspection

The bricks' physical and chemical properties are inspected very carefully by rigid quality management procedures.

Packing shipment

We guarantee efficient delivery every time.

Packing

We also supply (Click on following picture if interested):

- Q:What kind of refractory brick is used for industrial furnace?

- What kiln? Glass kiln, ceramic kiln, or blast furnace?

- Q:Shale brick and clay brick? Answer before you know it

- Has the advantages of high strength, thermal insulation, heat insulation, sound insulation and other characteristics, in order to shale as the main building materials brick construction, is the biggest advantage of shale brick and clay brick traditional construction method is exactly the same, without any additional special ` construction facilities, special tools, is the best substitute for traditional clay solid brick.

- Q:How to increase the service life of high temperature refractory bricks?

- The wedge brick should contain the brick surface distortion, decrease scrap rate high temperature refractory brick is refractory with a certain shape and size, the error of symmetry and concentric reducer's size differences. The correctness of shape of the straight refractory brick should include the straight of the intersection and the distortion of brick's face. Under the premise of ensuring the service life, the key to improve the efficiency of manufacturers, and have the correct shape and precise size. This is to ensure that the product is qualified, refractory brick in addition to planning a reasonable scale, that is, the scale of the allowable error.

- Q:What are needed to make refractory bricks with micro silica?

- Micro silicon powder is used in mortar and concrete, the ore-smelting electric furnace produces a large amount of strongly volatile gases SiO2 and Si, bridges, seaports. It is ferroalloy. When smelt ferrosilicon and industrial silicon (metallic cilicon), micro silicon power is also called silica fume or condensed silica fume, dam, gas emissions and air condensate and deposit by rapid oxidation, water conservancy, airport runway, tunnel, high-rise buildings, subway, railway, highway and culvert. Application fields of silicon power are cement concrete pavement and mine roadway anchor reinforcement and etc.

- Q:what effect does big mortar joints of the boiler refractory brick have on the boiler?

- The ventilation leakage。 Now the larger boilers are generally used refractory pouring material one-time pouring, the arch is easy to collapse . 2, shrinkage and expansion of brick will make the bricks fall. 1, do not use the refractory brick. too large seam will effect the tightness of furnace wall , and the water wall is easy to form dew and be corroded and to leak smoke.

- Q:What is the problem about splintering when the refractory brick is fired?

- There are many bubbles inside the refractory brick, it is also possible that the brick itself is not up to the standard about volume density, then refractory brick fragmentates. There are many reasons, may be in the process of repression

- Q:can diatomite?brick be used as thermal insulation refractory brick?

- yes, it has good thermal insulation the raw material is cheap, diatomite?brick is a kind of thermal insulation refractory brick with good performance.

- Q:What is refractory brick? What is refractory clay? ?

- Refractory brick is a kind of brick that is fireproof, refractory soil is the soil that is fireproof

- Q:can Methanol burn refractory brick?

- Generally speaking, all the fuel can burn, mainly to see the calorific value and consumption ratio

- Q:cement concrete What kind of cement should be used to manufacture high temperature resistant Kang cement?

- Portland slag cement 325 or 425. Use phosphate cement or aluminate cement. Use portland cement. You can also use the fragment and power of waste refractory brick or fireclay brick or aluminous refractory brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality SK34 Fireclay Brick for Industry Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords