High Quality PVB Film

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 30000M2 m.t.

- Supply Capability:

- 140000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

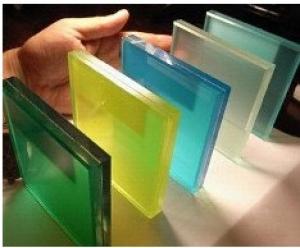

Production Specifications of High Quality PVB Film :

Polyinyl butyral film is made from PVB resin with plasticizer and prepared by the technology of extrusion and calendaring.

I t can be used as the inner layer of sandwich safety glass of cars, locomotive, airplane, tanker, naval vessel etc. It can also be used

as solid adhesive for safety glass, safety mask, building glazing, composite steel plate, etc. It conforms to the enterprise standard of

Q/GHAD 18-2008 .

TDS Of High Quality PVB Film

Item | Value | ||||

E-413J | E-413A | E-413B | E-413C | ||

Volatile content % ≤ | 2.0 | 2.0 | 2.0 | 2.0 | |

Tensile Strength MPa ≥ | 20.0 | 20.0 | 15.0 | 15.0 | |

Elongation @ Break % ≥ | 160 | 150 | 150 | 120 | |

Adhesive Strength MPa ≥ | 8.0 | 7.0 | 5.0 | 4.0 | |

Light Transmission Rate % ≥ | 81.0 | 80.0 | 80.0 | - | |

Fog % ≤ | 0.60 | 0.80 | - | - | |

Colourith% ≥ | 75 | 75 | 70 | - | |

Humid Heat | At 70±2, hum.91%-99%.After 48 hrs, sample no change. | At 60±2,hum. 91%-99%.After 8 hrs, sample no change. |

- | ||

Heat-Resistance | At 70±2,After 48 hrs, sample no change. | At 60±2,After 8 hrs, sample no change. |

- | ||

Cold-Resistance | At -55±2,After 48 hrs, sample no change. | At -55±2,After 8 hrs, sample no change. |

- | ||

Light-proof | Light transmission rate decrease less than 2% under 750W light-source, 100hrs | ||||

Usage of High Quality PVB Film :

With the Featurers of Transparent, heat- resistant, cold -resistant, wet-proof, high elasticity, without impurities, good softness, smooth surface with some roughness, good tensile strength and elasticity , the PVB Film can be widely used in Architecture and others.

Packing of High Quality PVB Film :

Vacuumed by aluminum foil and put into wooden cases , 10 Tons /20 FCL or as customers ' requiements .

- Q:After decorating, how can the plastic film on wooden board be peeled off?

- Take it off slowly. Maybe you are too impatient. You can use the blade carefully to expose the corner

- Q:What kind of material is plastic film?

- It depends on what kind of film it is. Plastic bags used in daily life are usually made of PE (polyethylene).Plastic greenhouse agricultural film, tape is generally made of PVC (PVC). The main thing is that these two quantities are larger.

- Q:Is there any toxicity in the production process of plastic blown film machine?

- Plastic blown film production process whether there is toxic or harmful gas production, mainly to see what kind of plastic. The production of polyethylene, polypropylene plastic film is not toxic, if the production of PVC plastic film, due to the heating and melting plastic parts plastic decomposition produces hydrogen chloride gas, it will cause harm to the human body.

- Q:Why is plastic film made of hand made paste of composite material?

- Glass steel production quality, surface quality is an important aspect, because only the smooth surface, smooth transition, the surface will completely cured resin, coherence, no weak points, in order to better erosion resistance medium. Hand paste operation itself is very difficult to do this. But the film is easy to improve, because the film itself is made of the machine, the surface is smooth and smooth, and the film has better toughness, can guarantee the convex, concave point transition smooth.

- Q:How to choose the plastic film for the salt packing bag?

- Indeed our common combination of corrugated carton packing bag, composed of inner and outer packing, is a kind of design idea, size material, performance, the design of the packing bag you need, but also need to design the packing box loading specifications, stacking layers, material strength, etc..

- Q:Rigid plastic film problems

- Generally there are three kinds of materials: PC, PET, PVCNormally, PC and PET belong to high-grade materials, the price is high, basically are used in electronic industry, PVC films are more general 0.05mm-0.125mm estimation can meet the requirements, but the material is environmental protection, which is also produced HCl toxic gas when burning, if there is high quality requirements of export or can not be used, see your customer requirements, other film may also be used for this, such as PE, but probably not hard enough

- Q:What are the factors affecting the puncture strength of plastic film?

- The specific operation is as follows: the diameter of test piece 100mm is installed on the fixed clamping ring like membrane, with a diameter of 1.0mm spherical apex radius of 0.5mm needle, thorn to the top with the speed of 50mm/min, the maximum load test piece read needle penetration. I hope I can help you.

- Q:What is the plastic film under the wooden floor?

- It's called damp proof cotton. It has thick and thin film with film and without film. You need to use a thick film to use, and the interface to connect

- Q:Can plastic film be printed?

- Plastic film printer operation is very simple without drying plate, various types of tools without the need for screen printing and thermal transfer needed, a computer, a plastic film printer, an exercise machine can be completely independent of the printing operation, save manpower, plastic film printer and printing method is simple. Lidengkequ, low requirement for operating crew experience, as long as the understanding of simple image processing software, careful attention to good use, daily maintenance, absolutely can very good use of the plastic film printer.

- Q:What is the function of the plastic film on the refrigerator cabinet?

- Because the SIEMENS refrigerator is in the refrigerator on both sides of the refrigerator, this layer of film will be blocked, the outer layer of film can effectively protect the appearance of the refrigerator, not quality problems, can rest assured that the use of! The ` `

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1988 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Central America; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PVB Film

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 30000M2 m.t.

- Supply Capability:

- 140000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products