High Quality PP Biaxial Geogrid 30KN/30KN for Civil Engineering Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

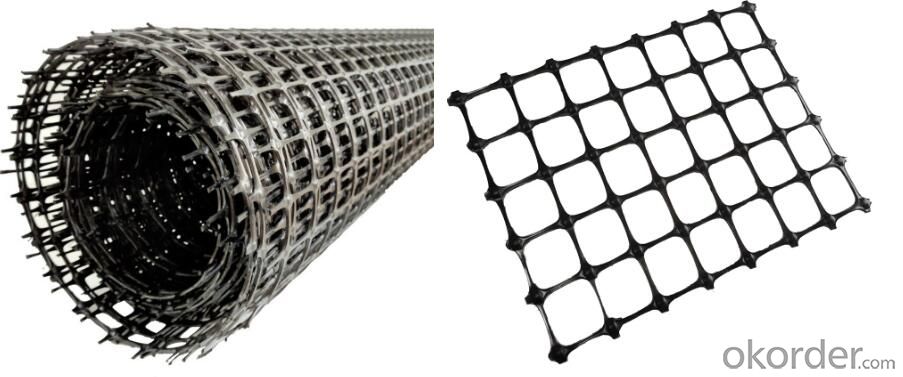

Introduction of Shandong High Quality PP Biaxial Geogrid 30KN/30KN:

PP Biaxial geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching, heating,

longitudinal stretching and transverse stretching.

Performance of High Quality PP Biaxial Geogrid 30KN/30KN:

---Homogeneous structure, low creep, anti-aging and resisting acid & alkaline.

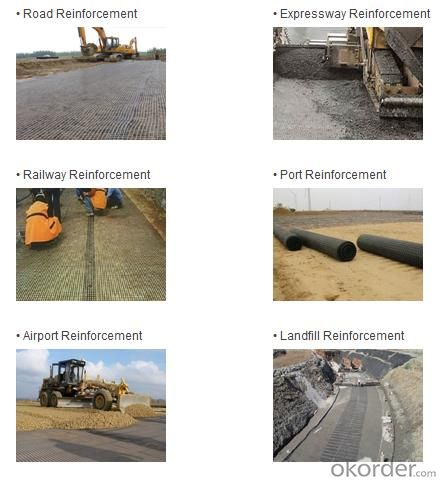

Applications of High Quality PP Biaxial Geogrid 30KN/30KN:

--Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement,

not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

--Used in highway, railway, port, airport and municipal project.

--Support in the recovery working face of coal mine and roadway in the coal mine.

Specifications of High Quality PP Biaxial Geogrid 30KN/30KN:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

- Q:Where is the best geogrid to do?

- Plastic grille mold Huangyan Xuan Ya mold to do very good, the price is also very suitable!

- Q:How do geogrids improve the performance of bridge abutments?

- Geogrids improve the performance of bridge abutments by providing reinforcement and stability to the soil surrounding the abutments. They distribute the loads more evenly, preventing soil erosion and reducing settlement. Additionally, geogrids enhance the overall strength and durability of the abutment, allowing it to withstand heavy traffic loads and natural forces such as earthquakes.

- Q:Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q:What is the meaning of the geogrid reinforced asphalt in the project list

- You are not me, I was the construction of geogrid manufacturers, generally used in the mygeogrid on the road of geogrid is fiberglass geogrid, in your compacted Subgrade after injection will then laying a layer or several layers of fiberglass geogrid, after paving asphalt, the operation process is this, geogrid and asphalt is two kinds of different products

- Q:Can geogrids be used in erosion control applications?

- Yes, geogrids can be used in erosion control applications. Geogrids are commonly used to reinforce soil and prevent erosion by providing stability to the ground. They help to distribute loads, improve soil retention, and increase the resistance to erosion caused by water or wind.

- Q:Can geogrids be used in bridge abutments?

- Yes, geogrids can be used in bridge abutments. Geogrids are commonly used as a soil reinforcement material to improve the stability and load-bearing capacity of soil structures, including bridge abutments. They help distribute the load from the bridge to surrounding soil, reducing settlement and improving overall performance and longevity of the structure.

- Q:Can geogrids be used in reinforcement of retaining walls?

- Yes, geogrids can be used in the reinforcement of retaining walls. Geogrids are commonly used in retaining wall construction to improve stability and strength. They are placed within the soil layers of the wall to provide additional support, prevent soil movement, and increase the overall load-bearing capacity of the structure.

- Q:How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They increase the tensile strength of the soil, preventing it from sliding or collapsing under heavy loads or external forces. Additionally, geogrids enhance the overall durability and longevity of the retaining structures by reducing soil erosion and improving drainage.

- Q:What are the factors that affect the cost-effectiveness of geogrids?

- The factors that affect the cost-effectiveness of geogrids include the quality and strength of the geogrid material, the size and complexity of the project, the type of soil being reinforced, the installation method, and the long-term performance and durability of the geogrid. Additionally, factors such as transportation and logistics costs, project timeline, and the availability of alternative solutions can also influence the overall cost-effectiveness of geogrids.

- Q:Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are commonly used to reinforce and stabilize soil in various construction applications, including temporary structures such as access roads, parking lots, and foundations. They provide strength and stability to the soil, preventing erosion and maintaining the integrity of the temporary construction project.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PP Biaxial Geogrid 30KN/30KN for Civil Engineering Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords