High Quality Pine LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m.t.

- Supply Capability:

- 3000 CBM per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

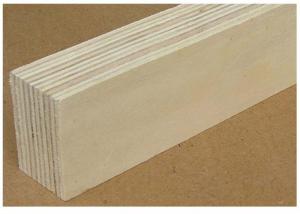

Specifications of the High Quality Pine LVL

| Size | Wide(Max.1250mm)*length(Max.6000mm) |

| Thickness | Max.50mm |

| Glue | WBP/melamine/MR |

| Material | pine wood |

| Usage | For construction headers, wood beams,rimboard,and edge forming material |

| Grade | A Grade |

| Package | standard export packing, pallet with metal strip |

Introduction of the High Quality Pine LVL

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layersof thin wood

assembled with adhesives. It offers several advantages over typical milled lumber.it is stronger, straighter,

and more uniform. It is much less likely than conventional lumber to warp twist, bow, or shrink due to its

composite nature. Made in a factory under controlled specifications,LVL products allow users to reduce

the onsite labor.

The usage of the High Quality Pine LVL

They are typically used for headers, beams, rimboard, and edge forming material.It is similar in

appearance to plywood without crossbands and is typically rated by the manufacturer for elasticmodulus

and allowable bending stress. Common elastic moduli are 1.8, 1.9, and 2.0 million psi, and common

allowable bending stress values are 2800 and 3000 psi.

Features of the High Quality Pine LVL

1.) High bending strength

2.) little liner expansion con efficient

3.) strong nail holding

4.) moisture proof and easy work

5.) tight construction and high stregth

6.) no ratten or decay

7.) low formaldehyde emission

The following pictures for your reference.

- Q:How to avoid wood deformation

- In order to keep the moisture content of wood stable, you should pay attention to the decoration: 1, the use of man-made sheet. Compared with solid wood materials, a variety of man-made sheet metal texture to be much more stable. As the solid wood materials are textured, so the temperature, humidity changes when the larger, there will be cracking, warping and deformation of the phenomenon. The wood-based panel is the decomposition of wood into wood or wood pulp, and then re-production of sheet metal. Because it broke the original physical structure of wood, so the temperature and humidity changes when the larger, wood-based panel "deformation" much smaller than the solid wood. 2, construction attention to detail. In the home decoration, the wood is the key to the quality of construction, especially the details of the deal: After all the wood products are installed, paint them once. This layer is called "overcoat" paint, not only can protect wood products, but also play a role in isolation of water to maintain the normal moisture content of wood; binder can not be mixed. At present in the home decoration, the general use of white latex for wood products joints of the binder. Some workers in order to cut corners, in the white latex watered. This not only reduces the strength of the binder, and wood products absorb moisture, it is prone to quality problems; all the wood to be placed for a few days. You in the decoration with the wood to buy home, the best place in the decoration site for a few days and then use. The purpose of this is to make the moisture content of the wood close to the level of new homes.

- Q:Why moldy wood products after cleaning will be moldy

- As the household goods and more, to have to concentrate on every one to have a certain degree of difficulty, the most critical thing is to do a good job home moisture protection. When the air is wet, do not open the window, remember to close the windows, especially south and southeast windows, as well as the highest air humidity sooner or later. But if you think the indoor air can not flow, you can open the doors and windows at noon and afternoon Dehumidification coup Moisturizing box for wardrobe, shoe moisture absorption, generally containing calcium chloride particles, most also added the essence, so set dehumidification, aroma, anti-mildew, deodorant and other functions in one. The use of absorbent bags is wider, in addition to dry clothing, but also on leather goods, books, cameras, computers, discs and other dehumidification. If placed in a confined space, the effect will be very good. Charcoal dehumidification is now the most popular moisture-proof way. Can be black wood charcoal in advance to boil for 10 minutes, filter out moisture, ventilated dry, put two days later placed in a breathable basket, placed in the room diagonal position can be. Each room put 5 to 10 kg or so. Charcoal cheap, and can be reused after the dry, affordable.

- Q:What are the characteristics of bamboo products?

- 3, solid wood flooring: Solid wood composite wood flooring is divided into three layers of solid wood flooring, multi-layer parquet, new solid wood flooring three, because it is made of different species of sheet staggered laminated, thus overcoming the shortcomings of solid wood floor unilateral homosexuality, Dry shrinkage expansion rate is small, with good dimensional stability, and retain the solid wood flooring natural wood and comfortable foot feeling. Solid wood flooring and strengthen the stability of composite wood flooring and solid wood flooring in one, but also has environmental advantages, high performance value of the new solid wood flooring, flooring should be the development trend of the industry. A floor dealer said that the solid wood flooring flooring to solve the solid wood flooring deformation is not wearable defects, and feet feel particularly comfortable, so that consumers can enjoy the warmth of nature, but also solve the ancient solid wood flooring difficult to maintain the shortcomings, Is to strengthen the wood flooring and solid wood flooring the crystallization of the people is the pursuit of high-end enjoyment. But its price is relatively high.

- Q:How to protect the outdoor wood products? What kind of paint can be anti-corrosion? How to build?

- 4. Before use, stir evenly, no need to dilute; if the product viscosity is high, but also into a small amount of special thinner, adding the amount should not exceed 10%. 5. Brush need to use soft brown hair brush, along the direction of wood texture evenly, thin brush again, after brushing to remove excess wood wax, brushing the amount must be less, can not be painted too thick; to be hard after the surface, Paint gently polished, wipe, 12 hours can be painted the second time.

- Q:What are the requirements for wood exports to Europe and the United States?

- From the export of logs to plywood, wood-based panel exports, and now to the main furniture exports, China's timber and wood products export value-added products are increasing.Currently, China's timber and wood products are the main features of wood-based panels and Wooden furniture exports accounted for a large proportion of the future, China's wood products export enterprises should be 'intensive cultivation' development. "Jinxiu wood chairman Cai Huixing that the domestic wood products related enterprises to do is to constantly adjust the industrial structure, Increase scientific and technological research and development to reduce dependence on the forest resources and destruction; the establishment of a more stable import resource base and channels to enhance the impact of fluctuations in the impact of international market prices; the establishment of a more standardized import order, to avoid self- Competition, weaken its competitiveness in the international market and undermine its image in the international market and so on, and strive to increase the added value of the product, the full open high-end market gap, from price to win to win.

- Q:Water content is too high or too low, will cause the quality of wood in the home improvement

- Because solid wood materials are textured, so the temperature, humidity changes when the larger, there will be cracking, warping with the deformation of the scene.

- Q:How to prevent cracking of wood products

- Prevent cracking Timber wood moisture content is the most critical point, the sweat needs to be lower, the lower the better, the lower the resulting deformation cracking probability is smaller. So in the case of conditions to choose wood to pay special attention to.

- Q:Wood furniture products which processes need constant temperature and humidity?

- 4, wood carbonization room or called wood carbonization Shu: for the processing and production of carbonized wood; 5, constant temperature and humidity warehouse or constant temperature and humidity library: for the finished wood products storage. The above five processes are required constant temperature and humidity environment, is a constant temperature and humidity system engineering in the wood products furniture industry applications.

- Q:How to fill out the export of wood products and wood furniture business self - control situation

- First, the purpose In order to meet the needs of customers, product quality in line with the importing country mandatory regulatory standards, to avoid product quality and safety problems, the company's export products required for raw and auxiliary materials, semi-finished products, finished special self-control self-control plan.

- Q:What is the color of wood products painted

- Is a propylene pigment, which is characterized by bright, easy to fade, dry faster, insoluble in water and the price is reasonable. If you try to draw pictures at home you can buy 12ml each, 32 colors, a box of twenty or thirty dollars Ma Li

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 1987 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Europe;North America;Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang;Qingdao |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 2000 |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

High Quality Pine LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m.t.

- Supply Capability:

- 3000 CBM per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords