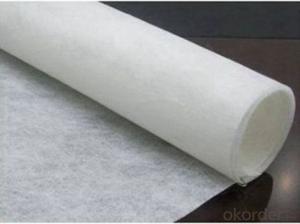

High Quality Non Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects. The main products are Synthetic staple fibers needle punched nonwoven geotextiles and split film yarn woven geotextiles.

Product introduction:

1.high quality geotextiles

2.CE, ISO9001, ISO14001

3 Sample available

4. 100-800g/m2

Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:The difference between lap and stitching

- In terms of popularity, the lap is a kind of overlapping, overlapping with each other interface method; and seam law is not overlapping, the use of docking method, will inevitably leave the gap, so called seam method. These two methods are used for geotextile construction, the construction requirements: When the use of lap connection, lap length should be 0.3 ~ 0.9m, the use of seam method, the bonding width of not less than 50mm, bonding strength of not less than The tensile strength of the material. On-site construction of the upper and lower joints should be staggered, staggered length of not less than 0.5m.

- Q:What are the advantages of using geotextiles in mining operations?

- There are several advantages of using geotextiles in mining operations. Firstly, geotextiles act as a barrier, preventing the erosion of soil and rock particles, thereby reducing the potential for soil contamination and water pollution. Secondly, geotextiles can strengthen and stabilize the ground, providing increased support for heavy machinery and equipment used in mining operations. Additionally, geotextiles can be used to separate different layers of soil and rock, allowing for efficient drainage and filtration of water, which is crucial for maintaining the integrity of mining sites. Overall, the use of geotextiles in mining operations enhances environmental protection, improves operational efficiency, and ensures the safety of workers and surrounding ecosystems.

- Q:Is there a geotextile for reed cultivation?

- Big slope pond words use better, need depth laying, with geomembrane

- Q:Can geotextiles be used in erosion control on riverbanks?

- Yes, geotextiles can be used in erosion control on riverbanks. Geotextiles are permeable fabrics that can be placed on the surface of the riverbank to stabilize the soil and prevent erosion. They help in retaining soil particles while allowing water to pass through, thereby reducing the impact of flowing water on the riverbank and preventing further erosion.

- Q:What are the different types of geotextile installation equipment?

- Some different types of geotextile installation equipment include geotextile rollers, geotextile spreaders, geotextile stitchers, and geotextile tensioners. These tools are used to properly position, secure, and connect geotextiles during installation for various applications such as erosion control, drainage, and reinforcement.

- Q:what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q:What are the key factors affecting the clogging behavior of geotextiles?

- The key factors affecting the clogging behavior of geotextiles include the size and type of particles in the surrounding soil, the hydraulic gradient, the flow rate and duration of water passing through the geotextile, and the quality and depth of the geotextile itself.

- Q:How do geotextiles help with sediment control?

- Geotextiles help with sediment control by acting as a barrier that prevents the transportation of sediment. They are used to stabilize soil and prevent erosion, allowing water to pass through while trapping sediment and silt. This helps in controlling sediment runoff, reducing soil erosion, and protecting water quality in various construction and environmental projects.

- Q:What are the uses of acupuncture geotextiles?

- Hello! You said there are two, the first is staple acupuncture non-woven geotextile, it is widely used in railways, highways, sports grounds, dam dams, water and soil construction, tunnels, coastal beaches, reclamation, environmental protection projects! The second is filament spunbonded acupuncture non-woven geotextile, which is widely used in the bottom of the landfill site, slope, closure of the reinforcement and protection, water conservancy project dam dam and slope of the filter, channel Isolation, seepage, road, rail, airport runway foundation isolation, filter ~ drainage! Soil slope, retaining wall and road reinforcement ~ drainage, port engineering soft foundation treatment, beach reclamation, port terminals and anti-slope reinforcement ~ drainage! I hope to help you, specializing in the production of geotechnical materials to answer!

- Q:Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Non Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords