High Quality Low Carbon stone 005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of low carbon stone

|

Raw material |

Sawdust, corn-straw and tailing, can be recycled after using. |

|

Technology |

Utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. |

|

Installation |

Stitching, wet-sticking and dry-fasten connecting |

|

Character |

Favorable corrosion resistance, non-ignitable, water-proof, UV-resistant, high resistance to fire, water and insects. |

|

Lead time |

30 days after receiving buyer's original L/C or Prepayment |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Four breakthroughs |

Comprehensive utilization of natural resources: Be recyclable, using sawdust, corn-straw and tailing as materials. The product can be recycled after using. |

|

Low carbon and energy saving in the course of production: Adopting the independent individual property’s technology, utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. | |

|

Environmental and healthy in the course of construction and using: Synthesized by natural inorganic raw materials, nontoxic, odorless and non-radiative simple installation, which could save energy cost and reduce and waste emission, raise efficiency and reduce erection time. | |

|

From nature, beyond nature: Full realization of the natural texture, high resistance to fire, water and insects. Do not rot or fade after long time usage. Super self-cleaning needs low maintenance cost. Vivid color and appearance provides a wide space to designers. | |

|

Six advantages |

Lower more than 50% cost, enhance building's performance to price ratio. |

|

Cutting at will, Fixing easy, Shorting project time. | |

|

Good performance in resistance to elements, corrosion-resistant ,resistance to termite, fire resistance and water-resistant, far from distortion and discolorations in 30 years. | |

|

Well self-cleaning, low cost in later maintenance: Don't need professional maintenance in 30s(Cleaning with water only), saving much cost. | |

|

Customize the color, showing individuation: Beyond 400 kinds of colors, designers could exhibit their imagination. | |

|

Compound with natural inorganic materials: Without formaldehyde and toluol, sustained releasing negative oxygen ion, forming nature oxygen bar. | |

|

Special specifications are available on customers' requirements. | |

Technical information of low carbon stone

|

Density |

1.23 g/m3 |

Folding strength |

15.4 Mpa |

|

Wet expansion rate |

0.32% |

Shear strength |

3.5Mpa |

|

Frost resistance |

Thaw-freeze cycle after 25 times, no slip crack and peeling off | ||

|

Formaldehyde release |

0.014mg/(m2·h) (GB/T 18587-2001) | ||

Specification of low carbon stone

Standard: 2400mm/3000mm(L)×1200mm(W)×12mm/20mm(T)

Standard length: 2400mm/3000mm

Standard width:300mm,400mm,600mm(including 3mm kerf width)

Standard thickness: 12mm/20mm

Product exhibition of low carbon stone

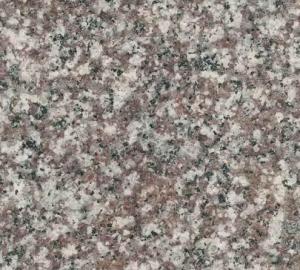

Low carbon stone with hole rock

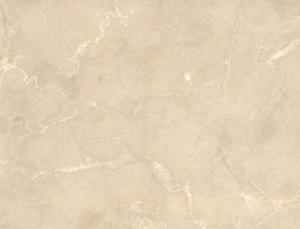

Low carbon stone

The project picture of low carbon stone

- Q:Artificial stone is a microcrystalline stone, what are the differences between them?

- There are many kinds of artificial stone, it is unsaturated polyester resin as binder, with natural marble or calcite, dolomite, silica sand, glass powder and other inorganic powder, and the amount of flame retardants, color, etc. Mixing, porcelain casting, vibration compression, extrusion and other methods made of curing.

- Q:Artificial jade (artificial marble) above the tea traces how to clear?

- Artificial marble products have excellent physical properties: food, gray tip, bacteria will not invade its surface. Routine maintenance only with sponge, Amway new multi-purpose concentrated detergent wipe, you can keep clean; to disinfect, can be diluted bleach and water (1: 1) or other disinfectant to wipe the surface. Please remember to use dry towels and into the water stains, try to keep the table dry.

- Q:Artificial stone TV background wall how fixed

- Artificial stone with colorful, wide variety, stain resistance, easy to clean, anti-chemical corrosion, non-porous structure, easy processing, installation without obvious patchwork and heating can bend the characteristics of these Features can be widely used in public places, home decoration and commercial background decoration. Such as: hotels, banks, hospitals, exhibition venues, laboratory bathrooms, counters, workstations, reception desk, etc. ; Home decoration cabinet countertops, sinks, kitchen walls, artificial stone, quartz stone table, coffee table, windowsill, door sets, TV artificial stone background and so on. And can be used in conjunction with glass, wood, stone, copper, metal, tile, plastic or different colors to achieve a variety of unique design, and by carving, sandblasting, laser etching made of various patterns. Artificial stone as a non-radioactive pollution, reusable environmental protection, green new building interior decoration materials, with its first-class quality and service, will lead the future decoration trend. For the major cabinet companies, decoration companies, furniture factory, bath cabinet factory, individuals, schools, hospitals, government agencies, aseptic laboratories, shops and other 来人 calls build all kinds of artificial stone, quartz stone countertops; Customers come home renovation, modification, maintenance of a variety of old artificial stone countertops, so that the table has a fresh feeling of recovery.

- Q:How the artificial stone on the high light

- Hit the wax with a polishing machine to wear wool ball with 4 files light hit, do not play more wax.

- Q:Artificial stone stove knife was cut a few India, how to repair into the original can not see it

- This is only looking for professional people because our family is also the results of the people I was careful to draw a few mark after the maintenance of stone people took a grinding machine is like grinding machine so grinding a few times like a little Can not see the fact that looking for a professional person to get you that is minutes of the thing that simple people who give you home by the artificial stone you find someone who will give you just do not want your money is particularly simple one Things do not give you money do not give me an extra score

- Q:Artificial stone countertops how to cut

- Artificial stone countertops processing technology 1, open material: According to the size of the drawings open the general small factory with a small hand-cut saw relatively large factory with a bridge cutting machine or horizontal cutting machine, when the open material is also a certain experience, can no longer corner open material. That will cause the effect is not good. Artificial stone countertop process is what 2, trimming: I use the cutting machine to open the material, there must be a lot of uneven place, in order to bond the smooth we need to repair the burr. So that the future work is also good to do. Out of the process will be more sophisticated, more highlights its value. 3, bonding: A, ready to repair the adhesive surface to bond the material. B, tune the special glue to join the appropriate amount of curing agent stir evenly. C, with a fixture clamping material to pay attention to the force of the fixture. 4, polished: Artificial stone countertops do not want jade as needed to be so professional and fine polished, but it also needs further processing. Adhesive molding of the table with the angle of the rough grinding machine can be polished a good polished, polished and polished a lot but pay attention to a law, polished to a layer of a layer, polished can be polished, polished before the first Wax, polished with wool polished cotton. Polished and polished out of the product more people feel the appearance of the better. Such products in the market can also sell a good price.

- Q:What are the resins used to produce artificial stone now

- 1, pure acrylic artificial stone (PMMA board). The main raw materials are methyl methacrylate, ultra-fine aluminum hydroxide (ATH), pigments. Pure acrylic artificial stone on behalf of: DuPont Corian resistance. 2, composite acrylic artificial stone (UP / PMMA board). Is a modified product with PMMA and unsaturated polyester resin. Such as DuPont Monterey. 3, the standard resin board artificial stone (UP board). The main raw materials are unsaturated polyester resin, aluminum hydroxide (ie, trihydrate alumina), pigment. 4, non-standard resin plate artificial stone. The main raw materials are unsaturated polyester resin, calcium powder or other stone powder, pigment. 5, artificial marble. Sub-resin type and non-resin type. The main raw materials of the resin type are unsaturated polyester resin, quartz sand, broken marble, calcite powder and so on. This resin-type artificial marble is essentially non-standard resin board artificial stone. Non-resin-type artificial marble refers to the use of cement as a binder or other methods made of artificial marble. 6, quartz stone artificial stone, is a small stone or stone synthesis of new technology artificial stone. The product is wrapped in more than 90% natural quartz stone or stone mixed with a high-performance resin and a special combination of pigments. Its main material is quartz. Representatives of such products are Spain's CosentinoS.A. (Corsenino) produced Sai Li Shi (English "Silestone")

- Q:Artificial marble has a scratch how to deal with

- For the more stubborn slight scratches, scratches, can be used to remove decontamination powder and water scrub paper or scouring pad.

- Q:How to protect the artificial marble countertops

- Strict contact with the surface of artificial stone contact with artificial chemicals. Artificial stone has a long-term anti-damage ability, but still need to avoid contact with the strong chemicals, such as paint agents, metal cleaning agents, stove cleaning agent. Do not touch methylene chloride, acetone (nail polish), strong acid cleaning agent. If you are inadvertently in contact with the above items, immediately rinse the artificial stone surface with plenty of soapy water. If the nail polish stained with acetone-free cleaning agent (such as: days that water, alcohol), and then washed with water. Do not let the heavy or sharp objects directly impact the surface: do not rinse with cold water immediately after the hot water.

- Q:Cabin Artificial stone countertop brand which is best

- Cloud stone is a higher than the cost of crystal stone, pattern imitation of natural lines, texture, hard artificial stone. Because of its processing and texture docking defects, has not been large-scale use, generally used in other external walls of packaging, columns, lighting packaging.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High;Average |

Send your message to us

High Quality Low Carbon stone 005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products