High Quality Low Carbon stone 003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of low carbon stone

|

Raw material |

Sawdust, corn-straw and tailing, can be recycled after using. |

|

Technology |

Utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. |

|

Installation |

Stitching, wet-sticking and dry-fasten connecting |

|

Character |

Favorable corrosion resistance, non-ignitable, water-proof, UV-resistant, high resistance to fire, water and insects. |

|

Lead time |

30 days after receiving buyer's original L/C or Prepayment |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Four breakthroughs |

Comprehensive utilization of natural resources: Be recyclable, using sawdust, corn-straw and tailing as materials. The product can be recycled after using. |

|

Low carbon and energy saving in the course of production: Adopting the independent individual property’s technology, utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. | |

|

Environmental and healthy in the course of construction and using: Synthesized by natural inorganic raw materials, nontoxic, odorless and non-radiative simple installation, which could save energy cost and reduce and waste emission, raise efficiency and reduce erection time. | |

|

From nature, beyond nature: Full realization of the natural texture, high resistance to fire, water and insects. Do not rot or fade after long time usage. Super self-cleaning needs low maintenance cost. Vivid color and appearance provides a wide space to designers. | |

|

Six advantages |

Lower more than 50% cost, enhance building's performance to price ratio. |

|

Cutting at will, Fixing easy, Shorting project time. | |

|

Good performance in resistance to elements, corrosion-resistant ,resistance to termite, fire resistance and water-resistant, far from distortion and discolorations in 30 years. | |

|

Well self-cleaning, low cost in later maintenance: Don't need professional maintenance in 30s(Cleaning with water only), saving much cost. | |

|

Customize the color, showing individuation: Beyond 400 kinds of colors, designers could exhibit their imagination. | |

|

Compound with natural inorganic materials: Without formaldehyde and toluol, sustained releasing negative oxygen ion, forming nature oxygen bar. | |

|

Special specifications are available on customers' requirements. | |

Technical information of low carbon stone

|

Density |

1.23 g/m3 |

Folding strength |

15.4 Mpa |

|

Wet expansion rate |

0.32% |

Shear strength |

3.5Mpa |

|

Frost resistance |

Thaw-freeze cycle after 25 times, no slip crack and peeling off | ||

|

Formaldehyde release |

0.014mg/(m2·h) (GB/T 18587-2001) | ||

Specification of low carbon stone

Standard: 2400mm/3000mm(L)×1200mm(W)×12mm/20mm(T)

Standard length: 2400mm/3000mm

Standard width:300mm,400mm,600mm(including 3mm kerf width)

Standard thickness: 12mm/20mm

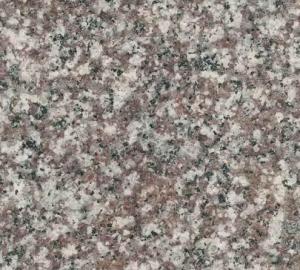

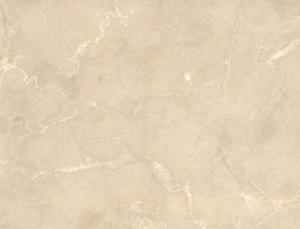

Product exhibition of low carbon stone

Low carbon stone with hole rock

Low carbon stone

The project picture of low carbon stone

- Q:Can man made marble with sand and cement?

- Polyester type: This artificial marble is unsaturated polyester as binder, and quartz sand, marble, calcite powder mixing, casting molding, curing agent in the role of curing, the stripping, drying, Polishing and other processes made. China to use this method to produce artificial marble.

- Q:What are the equipment and materials needed to produce artificial marble?

- Composite artificial marble This artificial marble is based on inorganic materials and organic polymer composite composition. After the filler is bonded and formed with an inorganic material, the green body is immersed in the organic monomer to polymerize under certain conditions. For the plate, the bottom with low and stable performance of inorganic materials, the surface layer with polyester and marble powder production. Sintered Artificial Marble This artificial marble is the feldspar, quartz, pyroxene, calcite powder and hematite powder and a small amount of kaolin and other mixed, with the mud preparation of blank, with semi-dry pressure molding,

- Q:Artificial stone is usually divided into several types?

- Artificial marble is divided into: cement-type artificial marble, resin-type artificial marble, composite artificial marble, sintered artificial marble. Among the four methods of making artificial marble, the most commonly used polyester artificial marble has the best physical and chemical properties, the pattern is easy to design, reproducible, suitable for a variety of uses, but the price is absolutely high; cement Type of artificial marble the lowest price, but poor corrosion resistance, easy to show micro-cracks, suitable for the plate and not suitable for sanitary ware; compound type is the combination of the strengths of the former two, both good physical and chemical properties, capital But also low; sintered artificial marble, although only clay as adhesive, but subject to high temperature roasting, so energy consumption, high cost, and high product breakage rate.

- Q:How to distinguish between man-made stone and natural stone?

- See the man-made artificial taste of artificial color distribution is generally very uniform natural anti-cut smell is the smell of stones is not a sour taste

- Q:Is it good for the guitar or the ceramic?

- Ceramics, recommended Graana, my home to buy. Spent six years, the quality is not bad. Artificial stone is good, ceramic fragile

- Q:How did the man with marble?

- Threshold stone, with artificial stone, natural fragile. I suggest you still use natural stone, artificial stone wear resistance worse

- Q:Artificial stone made of coffee table?

- At present, the stone table is the best quartz stone, in fact, is a man-made stone, but its hardness even more than the granite, but also has excellent toughness, even if the sudden hot and cold is not easy to crack, and not Will be soy sauce pollution, I have a friend with a white quartz stone bubble in the soy sauce inside for an hour, took out the rinse still very white. Quartz stone countertops is expected to become the mainstream of the kitchen countertops, in addition to the texture slightly monotonous, slightly more expensive price, really can not find any other shortcomings. More than the experience of my two colleagues and my colleagues to compare the actual comparison, absolutely reliable.

- Q:Does the countertop choose artificial stone or quartz stone? Artificial stone easy to crack?

- Cabin man - made stone countertops material advantages and disadvantages Advantages: Artificial stone is acrylic, there is no color difference Light weight: the user in the purchase of artificial stone do not have to worry about the existence of color and affect the cabinet effect. Artificial stone surface without pores, oil, water stains are not easy to penetrate one, strong anti-fouling, easy to clean. Artificial stone from the stone processing Wenzhou home improvement designer, thinner, its own weight lighter than natural stone, in the application can reduce the load-bearing cabinet to extend the service life. The use of artificial stone countertops, not only can be cut into a variety of shapes, combined into a variety of patterns, in the corner processing can also be done seamlessly. Artificial stone countertops is a natural mineral powder, high performance resin and natural pigments by vacuum casting or molding of mineral filled polymer composite materials, resin technology which contains functional additives, can be directly in contact with food, Is the best choice for environmentalists. Disadvantages: do not have resistance to tolerance, any material of artificial stone, Pakistan's hardness between 58 to 62, can not afford the metal and other sharp " (Refurbished to remedy).

- Q:Artificial stone countertops how to cut

- installation: There are many kinds of artificial stone countertops, because it uses different, can be used to do kitchen cabinets countertops. Floating window table, and even some of the bathroom table can be used. The general steps are as follows. A, adjust the cabinet flatness B, put the pad C, put the bench D, bonding (Note: in the field bonding surface is easy to do not be so strong to be reinforced in the bonding) E, polished and polished F, cleaning the scene

- Q:What is the current use of aluminum hydroxide powder and unsaturated resin, the need to add a specific type of brightener?

- Plus RQT-A-1 special effects whitening agent, can be better good resin combination, improve the artificial stone whiteness and permeability, add less, the effect is good.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High;Average |

Send your message to us

High Quality Low Carbon stone 003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products