High Quality Injection Molding Machine LOG-90A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OIL MOTOR : INTERMOT

DIRECTION VALVE: VICKERS

COMPUTER: MIRLE 9118

AC CONTACTOR : SCHNEIDER

ELECTRONIC RULER: NOVO

LUBICATION PUMP: HERG

| Model | UNIT | LOG-90A8 | |||

| International recognized model | 275/90 | ||||

| INJECTION | A | B | C | ||

| Shot volume | cm3 | 113 | 154 | 181 | |

| Injection | Shot weight | g | 106 | 144 | 170 |

| volume | |||||

| ps | Oz | 3.7 | 5.1 | 5.9 | |

| Screw diameter | mm | 30 | 35 | 38 | |

| Injection pressure | mpa | 243 | 179 | 152 | |

| Screw L:D ratio | 20:01 | 20:01 | 18:01 | ||

| Screw stroke | mm | 160 | |||

| Screw rotate speed | r/min | 0-180 | |||

| Clamping force | kn | 900 | |||

| Opening stroke | mm | 320 | |||

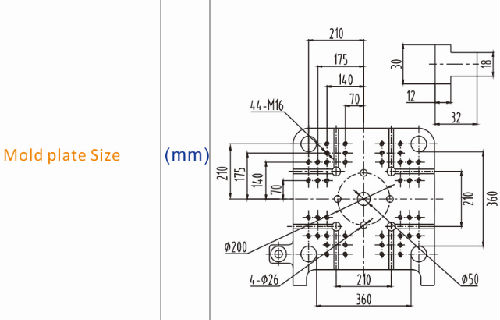

| Platen size | mm*mm | 540*540 | |||

| Space between tie bars | mm*mm | 360*360 | |||

| Mold thickness | mm | 150-360 | |||

| Platen Max stroke | mm | 680 | |||

| Ejection stroke | mm | 100 | |||

| Ejection force | kn | 31 | |||

| Hydraulic system pressure | mpa | 16 | |||

| Pump motor | kw | 9 | |||

| Heating power | kw | 6.5 | |||

| Number of temp.control | 3+射嘴(nozzle) | ||||

| Cycle time | sec | 1.1 | |||

| Oil tank capacity | L | 160 | |||

| Machine dimensions | m*m*m | 4.2*1.1*1.7 | |||

Products performance and advantages

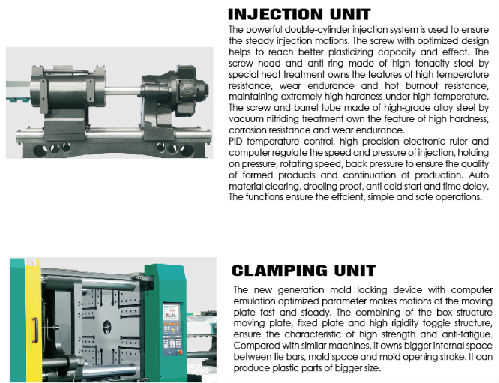

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

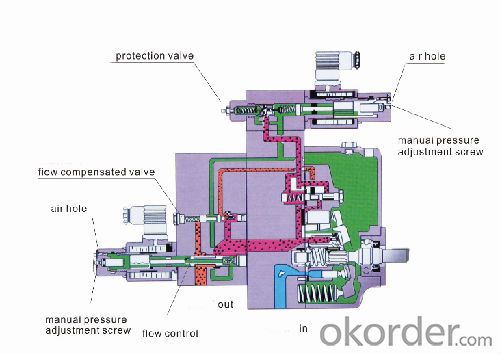

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

Products performance and advantages

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

Clamping system: Faster response, stable and high rigidity

Injection system: Accurate and flexible, lower rejection rate

Control system: Computer and simple operation,molding data memory system

Power system: Energy saving, high efficient and precise

Metal parts: The thickness of our frame, metal plate and wallboard are thicker than other company.

Other Information

Ceramic heating loop: Uniform heating, better thermal insulation properties so good for production

Visiable lubrication system: on time clean, avoid cast steel parts abrasion and broken.

Oil treasure: Filter of hydraulic oil,good for pump and valves

Long working life: Imported spare parts and updated version

Aftersales service: Professional & timely

Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Some vertical machines also don't require the mold to be fastened. There are many ways to fasten the tools to the platens, the most common being manual clamps (both halves are bolted to the platens); however hydraulic clamps (chocks are used to hold the tool in place) and magnetic clamps are also used. The magnetic and hydraulic clamps are used where fast tool changes are required.

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

- Q:How do you increase your product? How do you assign multiple segments? Speed? How to determine the holding position? Big, good or small? All help answer! Be deeply grateful!

- The distribution of each position and velocity, if familiar with the products of the case, according to the previously adjusted product size, short range, reducing the pressure and speed, the adjusted number of a few know it, and then slowly add pressure and velocity, and material. Process debugging did not say big products, good tune or small products good tune, this with your craft level, material, mold, equipment and so on have the factor.

- Q:What does injection machine mean by "short shoot"?

- A popular explanation is: in the test mode, because the materials in the barrel for so long, too much dissolved carbonation, put more easily cut waste of raw material, put less gun are not clean, speed is injected into the cavity under the condition of high temperature will be faster than normal, easy to swell that flash into the cavity around the gap is difficult to clean up, clean up the mold cavity more than expected a lot of work, the mold also has a certain degree of injury. So, start with a few shots or a short range, or reduce speed or pressure, to reach the effect of not filling, and then gradually full up until then, this is called short shot, but the local name is different. (it is recommended that the release agent be sprayed at the same time as the short shot)

- Q:Injection molding machine computer maintenance where professional?

- Shenzhen Jingcheng science and technology, can provide computer maintenance injection molding machine, injection molding machine computer (Philip series, Haitian quanlifa series series, Fuji series, Haitian, Haitian, PA series, Derek series, YIZUMI series, Bo Sea series, series, all kinds of injection molding machine computer decryption) injection molding machine parts, injection molding machine screen, control screen, all kinds of paper mask etc..

- Q:What is TMC injection molding machine?

- The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.TMC brand injection molding machine in the domestic similar products are high-grade products, export statistics in Taiwan for many years ranked first in three. Taiwan Qingyou also with precision, stable and reliable, injection molding machine technology and longevity, success will be "TMC" brand to the international marketing, more than 10 countries in Europe and the United States, Australia and South Africa, Southeast Asia, the establishment of the "TMC=HIGH QUAUTY" (high quality) image.

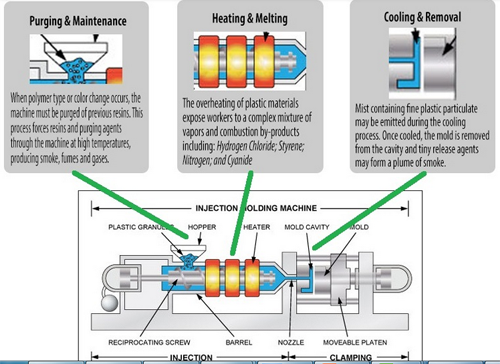

- Q:The working principle of injection molding machine

- The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products.Injection molding is a cycle process, each cycle mainly include: quantitative feeding - melt plasticization - pressure, injection - filling mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle.Injection molding machine operation items: injection molding machine operation items, including control keyboard operation, electrical control system operation and hydraulic system operation three aspects. The injection process, feeding action, injection pressure, injection speed, ejection type, temperature monitoring, injection pressure and back pressure adjustment are carried out respectively.The molding process of the general screw injection machine is first granular or powdered plastic into the machine barrel and then through the rotation of the screw and barrel wall heating the plastic as molten state, then the machine mold and the injection seat moves forward, to close the mold gate nozzle, the pressure oil through to the injection cylinder then, the screw to move forward at a high pressure and speed will melt into the closed mold temperature low, after a certain period of time and pressure (also called pressure), cooling, the curing, can remove mold products (pressure to prevent molten material the reflux, supplementary materials, to ensure the products with the mold cavity and the density and size tolerance in a certain cavity).

- Q:What injection molding machine is good?

- The vision for the company: "based on independent research and development, production and sales of plastic injection molding machine to become the first in the world of manufacturing enterprises,Actively lead the new trend of industry development."December 2006, Haitian Holdings Limited successfully listed on the SEHK (Hongkong stock exchange), initial public offering of shares.In August 2007, Haitian International Holdings Limited acquired Germany zhafir Plastics Machinery Manufacturing Co. ltd..Click hereChinese Machinery Association unitPresident of the Ningbo Association of machine unit

- Q:Please tell me the reason for choosing this tonnageFor example, an injection molding machine, water flow of 4 tons per hour, then 4 units on the election of 20T cooling tower is not enough? 20T's cooling water flow is about 18 cubic meters per hour

- The cooling water machine 160T~200T injection dosage of 160T~200T injection molding machine cooling water consumption is 4.2 m fand /H.4, it is 16.8m /H that is not considered fand, injection molding machine mold water chiller, water and water machine water situation.A proposal to buy water tower could buy, if continued to increase the machine, it would have to change a small tower, currently selected tower selected points (nothing big cooling effect is better, too much waste), and the 20t tower and 30t tower much money.20t traffic to 15.62m /H fand tower25t traffic to 19.51m /H fand tower30t traffic to 23.4m /H fand tower

- Q:How to change the suction filter core of injection molding machine?

- This is simple,The first ready to stop operation of filter, filter box machine behind the clockwise turn can be replaced, not what skills

- Q:How can I adjust the mold automatically when there is foreign matter in the mold? How about the location of the front and rear die blocks?. Be detailed and simple

- 1, low pressure clamping point, and even can go to zero,2, the speed is slow, as long as the mold in the fast mode locking inertia, continue to move on3, low voltage protection time is short.That is to say, the clamping force in the process of low voltage die clamping is smaller, the speed is slow, and the time of low voltage protection is short. Can play the role of low voltage protection, in the mold when there is foreign body, timely response, automatic mold opening.Set the position according to the actual situation of the mold.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Injection Molding Machine LOG-90A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords