High Quality Hot Sale WPC Outdoor Hollow Decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

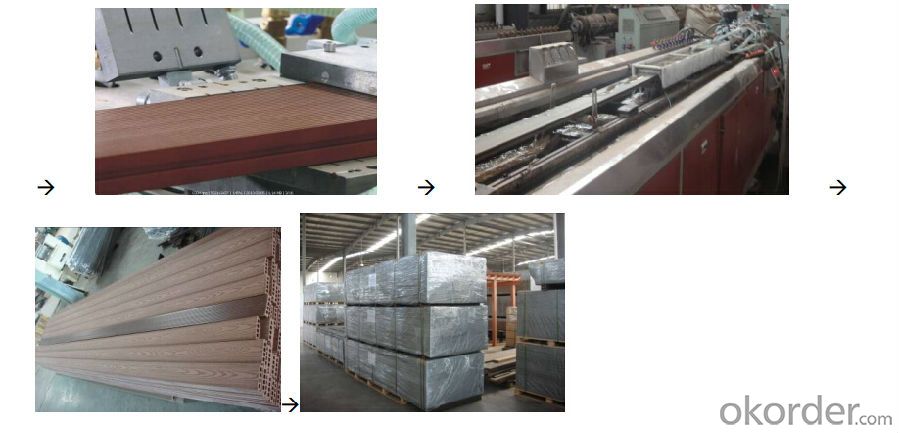

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

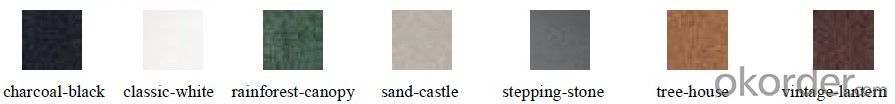

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

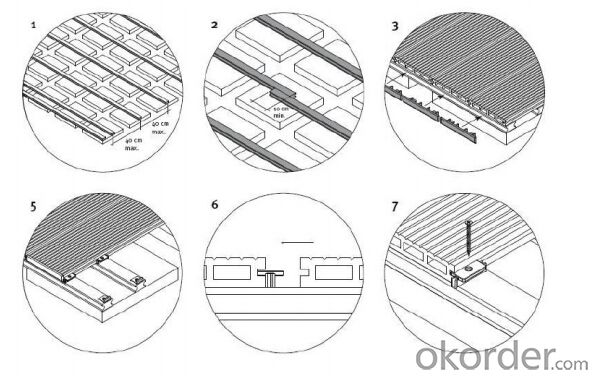

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q:Museum of the floor is not false

- Museum of the floor is rubbish floor, the opposite are wormhole, sales staff fraud, said a good board did not, can not change the good goods. So do not buy it.

- Q:Is It Possible For Me To Put Down Laminate Flooring Even If My Floors Aren't Perfectly Even?How?

- Yes......they can't be too crazy though. It's pretty much a floating floor. Talk to a professional installer. They will more than likely come over for a free in hime estimate.

- Q:Just removed an old lenoleum flooring, ( 50 years), and a Parkay floor. Do they make a floor sander or are there any chemicals that can be used?

- Hand floor scraper is your best bet. The glue from the Parquet will be very hard since these old glues almost crystallizes . Getting the high stuff off and then use a grinder if you need to get it to cement again. VERY dusty though..There are no solvents safe to use in a residential setting that will work . Depending on what you are going to put down again will determine just how clean you need to get the flooring. Any flooring questions you can e mail me through my avatar.GL

- Q:how to prove that floor(-x) = -ceiling(x) and that -floor(x) = ceiling(-x) show steps

- Let x= k+p where k is an integer and 0<=p<1 (obviously k is first integer less than x) floor(-x)=floor(-k-p) and since k or -k is an integer we can take it out of floor(or ceiling) floor(-x)=-k +floor(-p) floor(-p)=-1 when -1<-p<0 and floor(-p)=0 when p=0 -ceiling(x)=-ceiling(k+p)=-k - ceiling(p) ceiling(p)=1 when 0<p<1 and ceiling(p)=0 when p=0 then floor(-p)=-ceiling(p) thus we proved floor(-x)=-ceiling(x) ceiling(-x)=celing(-k-p)= -k + celing(-p) ceiling(-p)=0 when -1<-p<=0 -floor(x)=-floor(k+p)=-k - floor(p) -floor(p)=0 when 0<=p<1 then ceiling(-p)=-floor(p) thus we proved ceiling(-x)=-floor(x)

- Q:Find all real numbers x satisfying floor of (x+1/2) = floor xandFind all real numbers x satisfying ceiling of (x+1/2) = ceiling x

- Suppose floor(x+1/2) = floor(x). Then noting floor(x) is an integer and using the definition of floor(x+1/2), we have floor(x) <= x+1/2 < floor(x) + 1. Now, since we always have floor(x) <= x < x+1/2, the above inequality is equivalent to x - floor(x) < 1/2. Finally, this inequality has as solution the union of [m, m+1/2) where m is any integer. All of the steps I made are trivially reversible (either by definition or I gave an explanation), so that union is also the solution set for floor(x+1/2) = floor(x). --- You can very essentially mimic the above proof to get one for the ceiling, but I'll let you do so.

- Q:the people who we bought the house from just polished the floors right over dirt...is there anything that can be done?

- You need a liquid floor cleaner that contains ammonia. Ammonia is the secret ingredient that breaks down floor wax, as it goes after the cross-linked chemical bonds. You may need to use a high concentration of the cleaner, perhaps even use it straight, and allow it to soak in place for a few minutes to allow it to break down the wax. Then simply mop the floor to pick up the residue. A rotory floor scrubber (the type the professionals use) using either a mild abrasive pad or a polishing pad, will make the whole job faster. (don't use too abrasive of a pad, or it will damage the floor). Caution: avoid the temptation to use straight ammonia, as the vapors are too strong and could kill you! Just find a good quality floor cleaner that specifically states that it contains ammonia. Your local home center sells professional strength floor cleaners that will do the job.

- Q:I will be using prepaded laminate flooring on top of a concrete slab. Do I need to use an adhesive ? How does the floor stay down ?

- is it a rolled sheet laminate floor? if so then yes u will need an adhesive to told it down...the direction on the glue will tell u what size V shaped notched trowel to use...must of the time you'll need a 1/8 trowel.....roll back the flooring half way and apply the glue to the floor....fold back over glue and press into place....u can rent a 100 lb. roller for this which help it stick to the floor and squeezes all the air out from underneath ...repeat for the other half of flooring....if no roller then press the floor into place with a soft towel

- Q:I have cleaned, degreased, and filled cracks in the garage floor (let cure 10 days). It has been powerwashed and swept (you could eat off of it now). I mixed the etching solution according to the directions and applied to pre moistened garage floor. The directions state that if the solution does not fizz the floor is sealed and needs further prep and that if it does fizz it will do so for 4-5 minutes. I applied the etching solution and it did fizz but for a very short time (Less than 1 min). Also, the floor does not feel very rough...in fact, I can't tell any difference from now to when there was nothing done besides cleaning. Any suggestions from someone that has used this product or has knowledge of etching would be much appreciated.

- Rocksolid Floor

- Q:Solid wood composite floor with enhanced floor than, which is good?

- Solid wood flooring to better point but to pay attention to both the formaldehyde content and free formaldehyde emission is up to standard

- Q:Does it matter what type of surface you do workouts on, i am working and improving my ab muscles and the exercises are all done on on the floor. Will doing it on the floor instead of a mat make any difference? will it cause any problems?

- Nope, just your comfort level. If you are fine doing your exercises on a hardwood floor, more power to you. You'll most likely find you'll be wanting that mat, though. You can also substitute folded towels or rugs, if you don't want to spring for the mat. One thing I will say is that if you're doing any type of high impact exercises, softer flooring helps protect your joints, like your ankles, knees, and hips.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Hot Sale WPC Outdoor Hollow Decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products