High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

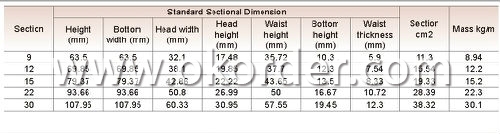

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Usages of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ

Q1: What is the normal tolerance of High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20inches the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:Can steel rails be used in railway bridges or viaducts?

- Yes, steel rails can be used in railway bridges or viaducts. Steel rails provide strength and durability, making them suitable for supporting heavy loads and ensuring the safe passage of trains over long spans. Additionally, steel rails can be designed to withstand various environmental conditions, making them a preferred choice for railway infrastructure projects.

- Q:What is the process of installing steel rails on bridges?

- The process of installing steel rails on bridges involves several steps. Firstly, a detailed survey and inspection of the bridge is conducted to assess its condition and determine the type and length of steel rails required. This information is crucial for ensuring the rails meet the necessary specifications and can withstand the expected loads and stresses. Next, the existing railings or guardrails on the bridge are removed, creating a clear space for installing the new steel rails. The removal process may involve cutting, unscrewing, or dismantling the existing railings, depending on their design and attachment method. Once the area is clear, the steel rails are brought to the bridge site. These rails are typically pre-fabricated sections that are designed to fit together seamlessly. The rails are often delivered in sections that are easily manageable and can be transported to the installation location. The rails are then positioned along the edge of the bridge, aligning them with the pre-marked locations. In some cases, temporary support structures or brackets may be used to hold the rails in place temporarily while the installation process continues. These supports ensure that the rails remain stable and secure during the installation. After the rails are positioned, they are anchored to the bridge structure using bolts or other fastening mechanisms. These fasteners are inserted through pre-drilled holes in the rails and are secured to the bridge to provide a strong and durable connection. Once the rails are securely anchored, they are inspected for any defects or inconsistencies. If any issues are found, necessary adjustments or repairs are made to ensure the rails meet the required standards and regulations. Finally, the installation process is completed by conducting a thorough inspection of the entire rail system to ensure it is properly aligned, securely fastened, and meets all safety requirements. This inspection may involve using specialized tools and equipment to measure the alignment, stability, and integrity of the rails. Overall, the process of installing steel rails on bridges requires careful planning, precise measurements, and skilled labor to ensure a safe and effective installation.

- Q:How are steel rails protected from weathering?

- Steel rails are protected from weathering through a process called corrosion prevention. This involves the application of various protective coatings to the surface of the rail, which act as a barrier against moisture, oxygen, and other corrosive elements in the environment. The most commonly used coating for steel rails is zinc, applied through a process called galvanization. Galvanization involves immersing the rail in a bath of molten zinc, which forms a protective layer over the steel surface. This zinc coating not only prevents direct contact between the steel and the environment but also acts as a sacrificial layer, corroding instead of the steel in the presence of moisture or other corrosive agents. Additionally, periodic maintenance and inspection of the rails are carried out to identify any signs of corrosion or damage and to promptly address them before they become more severe. Overall, these protective measures ensure that steel rails remain durable and resistant to weathering, extending their lifespan and maintaining the safety and efficiency of railway systems.

- Q:How are steel rails protected against excessive heat?

- Steel rails are protected against excessive heat through a process called heat treatment. This involves subjecting the steel rails to controlled heating and cooling cycles to enhance their strength, hardness, and resistance to heat-related damage. Additionally, railways use various cooling techniques, such as water spraying systems, to prevent the rails from reaching critical temperatures during extreme heat conditions.

- Q:Who are the major manufacturers of steel rails?

- Some of the major manufacturers of steel rails include ArcelorMittal, Tata Steel, Nippon Steel Corporation, POSCO, Baosteel Group Corporation, Jiangsu Shagang Group, Anyang Iron & Steel Group, EVRAZ, and Riva Group. These companies have established their presence globally and have a significant market share in the production of steel rails. Additionally, there are several other manufacturers operating regionally or locally, but these companies represent the leading players in the industry.

- Q:How are steel rails protected against wear caused by train wheels?

- Steel rails are protected against wear caused by train wheels through regular maintenance practices such as grinding, lubrication, and periodic replacement. Additionally, the use of high-quality steel and proper alignment of the tracks helps to minimize wear and extend the lifespan of the rails.

- Q:What is the role of steel rails in reducing train energy consumption?

- The role of steel rails in reducing train energy consumption is to provide a smooth and efficient surface for trains to travel on. By minimizing friction and resistance, steel rails help trains to move with less effort and therefore consume less energy.

- Q:What is the role of steel rails in reducing train noise?

- The role of steel rails in reducing train noise is primarily to provide a smooth and stable surface for the train wheels to roll on. Steel rails are designed to be durable and precisely aligned, which helps minimize vibrations and noise generated by the train's movement. Additionally, the use of steel rails allows for better weight distribution and reduces friction between the wheels and tracks, further reducing noise levels.

- Q:What are the different types of steel rail track monitoring systems?

- There are several types of steel rail track monitoring systems, including track geometry measurement systems, rail defect detection systems, wheel impact load detectors, and acoustic monitoring systems. These systems employ various technologies such as lasers, ultrasonic sensors, accelerometers, and acoustic sensors to monitor the condition of the rail track, detect defects, measure track geometry parameters, identify wheel impacts, and identify abnormal vibrations or noise. These monitoring systems help ensure the safety and efficiency of railway operations by providing real-time data for maintenance and inspection purposes.

- Q:What are the environmental impacts of steel rails production?

- The production of steel rails has several environmental impacts. Firstly, the extraction of raw materials such as iron ore and coal for steel production can lead to habitat destruction and deforestation. Additionally, the mining and transportation of these materials consume significant amounts of energy and emit greenhouse gases, contributing to climate change. The steel manufacturing process itself also generates air and water pollution, including emissions of carbon dioxide, sulfur dioxide, and heavy metals. Moreover, the production of steel rails requires large amounts of water, which can put strain on local water sources and ecosystems. Overall, the environmental impacts of steel rails production highlight the need for sustainable practices and alternative materials in the construction of railway infrastructure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Hot Rolled Light Steel Rail for Minas Q235,55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords