High Quality Food Approved White PU / PVC Conveyor Belts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Processing Conveyor Belt

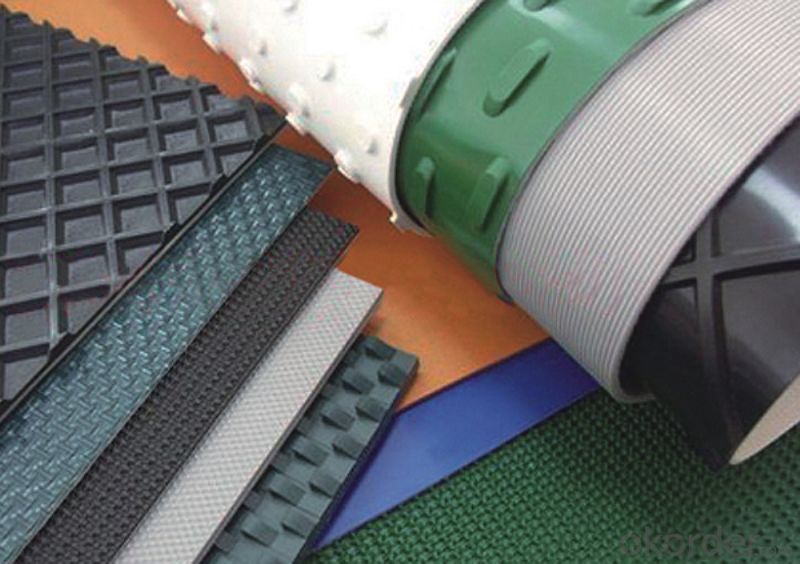

Food Processing Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:How many grades are there in the plastic block? How to divide?

- Flame retardant grade bottom HB:UL94 CSA and C22.2 No 0.17 standard, requirements for 3 to 13 mm thick sample, the burning rate is less than 40 mm per minute; less than 3 mm thick sample, the burning rate is less than 70 mm per minute; or extinguished in 100 mm signs before.V-2: the flame was extinguished in 60 seconds after the two and 10 second combustion test of the sample. A fire can fall off.V-1: the flame was extinguished in 60 seconds after the two and 10 second combustion test of the sample. No fire can fall.V-0: the flame was extinguished in 30 seconds after the two and 10 second combustion test of the sample. No fire can fall.

- Q:Why should I granulate before injection? What's the advantage of granulation?

- Direct crushing material can also be used, but the direct crushing of the material due to uneven particle size, resulting in uneven storage process, the process becomes more unstable. And granulation, the particles are generally more homogeneous, and later injection molding process is relatively stable! As for the difference between granulation and injection: This is the two process, granulation is a number of waste plastics through melting, extrusion, in the cutting machine to cut into granular. During the granulation process, some additives can be added to improve the performance of waste plastics. Something like a toughening agent. Plastic injection is the formation of plastic products by melting the plastic material and then by pressing it into the mold. Popular to say is: injection molding is the raw material into plastic products, and granulation is to make plastic products again "raw material""!

- Q:Do olive nets impact the size of the olives?

- Yes, olive nets can impact the size of the olives. Olive nets are used to protect olive trees from birds and other animals, reducing the risk of damage or loss. By preventing external factors from affecting the olives, such as bird pecking or wind damage, olive nets can help promote healthier growth and potentially result in larger-sized olives.

- Q:Do olive nets require any special training for installation?

- No, olive nets do not require any special training for installation. They are relatively easy to install and can be done by anyone with basic knowledge and understanding of the process.

- Q:Advantages and disadvantages of plastics

- The plastic can be processed into various shapes according to the requirement of use, and the processing technology is simple, and the machine is suitable for large-scale production by mechanization.

- Q:Can olive nets be used for both outdoor and indoor olive tree cultivation?

- Yes, olive nets can be used for both outdoor and indoor olive tree cultivation. Olive nets are commonly used to protect the olives from birds and other animals, as well as to collect the falling fruit during harvest. Whether the olive tree is grown outdoors or indoors, using olive nets can help ensure a successful cultivation process.

- Q:How does an olive net affect the overall fruit oil content in the olive grove?

- An olive net can positively affect the overall fruit oil content in an olive grove. By placing the netting over the trees, it helps to protect the olives from external factors like wind, pests, and excessive sun exposure. This protection allows the olives to ripen more evenly and retain their moisture, resulting in higher oil content. Additionally, the netting can prevent olives from falling to the ground prematurely, ensuring that only fully matured olives are harvested, which typically have higher oil content.

- Q:Are there any specific guidelines for using olive nets on olive trees with specific soil requirements?

- Yes, there are specific guidelines for using olive nets on olive trees with specific soil requirements. It is essential to select well-drained soil with a pH level between 5.5 and 8.5 for optimal olive tree growth. Additionally, the soil should have good fertility and be rich in organic matter. Adequate irrigation and proper fertilization are also crucial for healthy olive tree growth.

- Q:Can olive nets be used for olive trees in regions with heavy rainfall?

- Yes, olive nets can be used for olive trees in regions with heavy rainfall. Olive nets are typically used to protect the olives from birds and pests, and they can also provide some protection against heavy rains. However, it is important to note that excessive rainfall can still have negative effects on olive trees, such as causing root rot or fruit splitting. Therefore, while olive nets can offer some protection, additional measures should be considered to mitigate the potential risks associated with heavy rainfall in such regions.

- Q:Are there any disadvantages of using olive nets?

- Yes, there are a few disadvantages of using olive nets. Firstly, olive nets can be quite expensive to purchase and maintain. They require regular cleaning and maintenance to ensure they remain effective. Additionally, olive nets can be time-consuming to set up and take down, especially in larger orchards. They can also obstruct sunlight, potentially affecting the growth and health of the olive trees. Finally, if not properly secured, olive nets can pose a hazard to wildlife and may inadvertently trap or harm birds and other animals.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Food Approved White PU / PVC Conveyor Belts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords