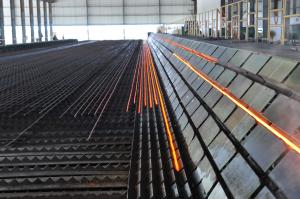

High Quality Deformed Steel Bar For Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Quality Deformed Steel Bar For Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Deformed Steel Bar For Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality Deformed Steel Bar For Construction are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: HRB335

Size: 6mm-25mm

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | B | |||

HRB335 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%) | ||||||

≥335 | ≥490 | ≥16 | ||||||

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%) | ||||||

≥400 | ≥570 | ≥14 | ||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: what is the difference between actual weight and theoretical weight?

A3: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

.

Images:

- Q:What is the role of steel rebars in ensuring occupant safety?

- Various structures, particularly buildings and infrastructure, rely on steel rebars to ensure occupant safety. These reinforced steel bars are commonly used in concrete construction to strengthen and prolong the lifespan of the structure. Ultimately, this safeguards the individuals residing or working within these structures. Steel rebars have a primary function of providing structural reinforcement to concrete elements like columns, beams, and slabs. By incorporating rebars into the concrete, the overall load-bearing capacity of the structure is greatly increased. This allows it to endure external forces and loads, significantly reducing the risk of collapse or structural failure that could harm the occupants. During seismic events, such as earthquakes, steel rebars play a crucial role in dissipating and distributing the energy exerted on the structure. The ductility and tensile strength of steel enable it to absorb and distribute seismic forces, minimizing the chances of a sudden structural failure. Consequently, occupants are protected from potential hazards associated with seismic activity. Additionally, steel rebars enhance the fire resistance of concrete structures. While concrete itself possesses good fire-resistant properties, the inclusion of steel rebars further strengthens this resistance. Steel has a high melting point and low thermal conductivity compared to other materials. This means that steel rebars can withstand high temperatures for an extended period, ensuring the building's structural integrity during a fire and providing occupants with a safe evacuation route. Furthermore, steel rebars contribute to the long-term durability and maintenance of the structure. They prevent cracks and minimize the effects of corrosion, maintaining the concrete's structural integrity over time. This ensures that occupants are not exposed to potential hazards caused by structural deterioration. In summary, the role of steel rebars in ensuring occupant safety is essential. They provide structural reinforcement, increase load-bearing capacity, enhance fire resistance, and contribute to the long-term durability of a structure. By incorporating steel rebars into concrete construction, the risk of collapse, structural failure, and other potential hazards is significantly reduced, ultimately creating a safe environment for occupants.

- Q:Can steel rebars be used in seismic-resistant construction?

- Yes, steel rebars can be used in seismic-resistant construction. Steel rebars are commonly used in reinforced concrete structures to enhance their strength and durability, making them suitable for withstanding seismic forces. By reinforcing the concrete with steel rebars, the structure becomes more resistant to the lateral and vertical movements caused by earthquakes, thereby improving the building's seismic performance.

- Q:What are steel rebars?

- Steel rebars, also known as reinforcement bars, are steel bars or rods that are used to strengthen and reinforce concrete structures. They are typically embedded within the concrete to provide tensile strength, preventing cracks and enhancing the structural integrity of buildings, bridges, and other infrastructure projects.

- Q:How are steel rebars used in construction?

- Steel rebars are used in construction to reinforce concrete structures and provide them with increased strength and durability. They are embedded within the concrete to withstand tension forces and prevent cracking or collapsing, ensuring the structural integrity of buildings, bridges, and other infrastructure projects.

- Q:What are the guidelines for the proper spacing of steel rebars in slabs?

- The guidelines for proper spacing of steel rebars in slabs typically vary depending on the specific design and structural requirements. However, some general guidelines recommend a minimum spacing of rebars to be at least three times the diameter of the longitudinal bars. Additionally, transverse reinforcement should be placed at regular intervals, typically between 12 to 18 inches, to ensure adequate reinforcement throughout the slab. It is crucial to consult with a structural engineer or refer to local building codes and standards to determine the specific spacing requirements for a given project.

- Q:What are the safety precautions when handling steel rebars?

- When handling steel rebars, there are several safety precautions that should be followed to minimize the risk of accidents or injuries. These precautions include: 1. Personal Protective Equipment (PPE): It is essential to wear the appropriate PPE when handling steel rebars. This includes steel-toe boots, gloves, safety glasses, and a hard hat. PPE will protect against potential hazards such as falling rebars or flying debris. 2. Lifting and Carrying Techniques: Steel rebars can be heavy and difficult to handle. It is important to use proper lifting techniques to avoid strain or injury. Bend at the knees, not the waist, and use the leg muscles to lift the rebar. It is also crucial to avoid overexertion and ask for assistance when handling heavy rebars. 3. Proper Storage: Steel rebars should be stored in a secure and organized manner to prevent them from falling or rolling. Rebars should be stacked flat and not leaning against walls or other structures. Additionally, rebars should be stored away from high traffic areas to avoid accidental collisions. 4. Sharp Edges: Steel rebars have sharp edges that can cause cuts or puncture wounds. It is important to handle rebars with caution and wear gloves to protect the hands. Additionally, rebars should be stored and transported in a way that minimizes the risk of coming into contact with sharp edges. 5. Communication and Warning Signs: When working with steel rebars, it is important to communicate with coworkers and warn them of any potential hazards or activities involving rebars. Clear signage should be posted in work areas to alert others to the presence of rebars and the need for caution. 6. Training and Supervision: Workers should receive proper training on the safe handling and storage of steel rebars. Supervisors should closely monitor work areas to ensure that safety protocols are being followed and provide guidance or corrective action as needed. By following these safety precautions, the risk of accidents or injuries when handling steel rebars can be significantly reduced. It is important to prioritize safety at all times to create a secure working environment.

- Q:Do steel rebars need to be coated with any protective materials?

- Yes, steel rebars often require a protective coating to prevent corrosion and extend their lifespan. Coatings such as epoxy, zinc, or galvanized coatings are commonly used to protect rebars from environmental factors and ensure their structural integrity in reinforced concrete structures.

- Q:Can steel rebars be used in structures with high sulfate content in soil or water?

- In structures that contain high sulfate levels in soil or water, it is not recommended to use steel rebars. The reaction between sulfates and steel, specifically the iron within the steel rebars, can result in corrosion and the weakening of the structure. This phenomenon, commonly referred to as sulfide attack or sulfate attack, has the potential to lead to the deterioration of the rebars and ultimately compromise the overall integrity of the structure. As a result, it is advisable to explore alternative materials such as stainless steel rebars or non-metallic reinforcement options like fiber-reinforced polymers (FRP) in order to ensure the longevity and safety of the structure.

- Q:How are steel rebars cut on-site?

- Steel rebars are typically cut on-site using a variety of tools such as a rebar cutter or a portable hydraulic shear. These tools are specifically designed to provide precise and efficient cutting of steel rebars, ensuring that they are accurately sized for construction purposes.

- Q:How are steel rebars bent or shaped to fit specific construction requirements?

- Steel rebars are commonly bent or shaped to fit specific construction requirements through a process known as rebar bending. This process involves the use of specialized machines that apply force to the rebar, causing it to bend or shape according to the desired specifications. There are different methods used to bend steel rebars, depending on the complexity of the required shape. For simpler bends, such as 90-degree angles, manual bending tools like hammers or manual rebar benders can be used. These tools allow construction workers to manually apply force and shape the rebar by hand. However, for more complex shapes or larger quantities of rebars, mechanical rebar benders are often employed. These machines are equipped with bending dies and rollers that can bend the steel rebar with greater precision and efficiency. They can be manually operated or powered by hydraulics or electricity, depending on the size and requirement of the construction project. Computer Numerical Control (CNC) machines are also utilized in some cases, especially for projects with intricate or customized rebar shapes. These machines are programmed to automatically bend the rebars to the desired angles and shapes, ensuring high precision and accuracy in the construction process. It is worth noting that rebar bending is not limited to simple bends or shapes. In some cases, rebars need to be curved or spiraled to fit specific architectural or structural requirements. This process involves the use of specialized bending machines that can apply gradual and controlled force to the rebar, resulting in smooth curves or spirals. Overall, the process of bending or shaping steel rebars to fit specific construction requirements involves the use of manual tools, mechanical benders, or CNC machines. These methods ensure that the rebars are precisely bent or shaped according to the design specifications, allowing for the efficient and accurate construction of reinforced concrete structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Deformed Steel Bar For Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords