High Quality Deep Well Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 35000台 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high quality 2 cubic meter per hour 0.37kW Deep Well Pump

◊ APPLICATION

For water supply from wells or reservoirs.

For domestic use, for civil and industrial applications.

For garden use and irrigation.

◊ MOTOR AND PUMP

1. Rewindable motor

2. Equip with start control box or digital auto-control box

3. Pumps are designed by casing stressed

4. NEMA dimension standards

◊ OPERATING LIMITS

1. Maximum fluid temperature up to +40℃

2. Maximum sand content: 0.25%

3. Maximum immersion: 80m

4. Minimum well diameter: 4”

◊ FEATURES

1. CE certificate

2. 100% copper wire, automatic wiring

3. Cold-rolled silicon steel sheet, with high-speed punching, improve the efficiency and precision.

4. CNC precision automatic lathe for smoother shaft.

5. Strict tests include water test, outgas test and performance test, ect.

6. Anti-rust treatment castings and electrophoresis.

Material | |

Pump external casing | AISI 304 SS AISI 201 SS |

Delivery casing | Cast-Cu AISI 304 SS |

Suction lantern | Cast-Cu AISI 304 SS |

Diffuser | Plastic PC |

Impeller | Plastic POM |

Shaft | AISI 316 SS AISI 304 SS |

Shaft coupling | AISI 316 SS AISI 304 SS |

Wear ring | AISI 304 SS |

Motor external casing | AISI 304 SS AISI 201 SS |

Top chock | Cast-Cu Cast-iron |

Bottom support | AISI 304 SS |

Mechanical seal | Special seal for deep well (carbon-SIT/TC) |

Shaft | AISI 304 SS |

Bearing | NSK C&U |

Seal lubricant oil | Oil for food machinery and pharmaceutical use |

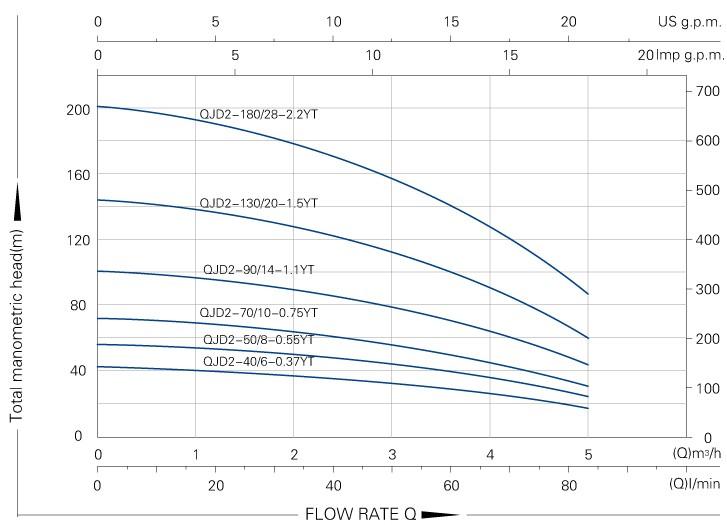

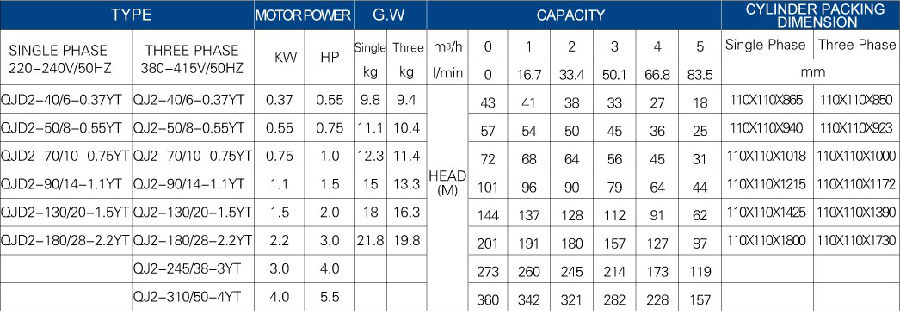

◊ TECHNICAL DATA

- Q:Working principle and structure of external gear pump

- When the meshing teeth on one side of the suction chamber are gradually separated, the volume of the suction chamber is increased, and the pressure is lowered, and the liquid in the suction pipe is sucked into the pump; the suction liquid is divided into two parts to be pushed into the discharge chamber by the gear in the alveolus. When the liquid enters the exhaust chamber, the liquid is squeezed and discharged from the exhaust chamber into the discharge pipe because the teeth of the two gears are continuously engaged. The driving gear and the driven gear keep rotating, and the pump can continuously inhale and discharge the liquid. The pump body is equipped with a safety valve, when the discharge pressure exceeds the required pressure, the delivery liquid can automatically open the safety valve, so that the high-pressure liquid returns to the suction pipe.

- Q:If the calculation of the required pump flow is 45, lift 110, and the actual pump flow 100, head 125, what will happen in operation? Can I use it properly?

- First of all, the performance curve of the centrifugal pump is similar to the track of the train, and the train can not run away from the track.Secondly, the performance curves of centrifugal pump mainly include flow head curve, efficiency flow curve, power flow curve. When the pump is ready, the curve is fixed. In practical application, after determining the flow rate, the corresponding lift head, efficiency and power (relative to density) are determined. General requirements for centrifugal pump operating in the vicinity at the highest point of efficiency, the efficiency of the flow curve is similar to parabola, so if the actual operation condition deviated from the rated point, whether large or small, will cause the decline in pump efficiency (generally rated value is less than 15%), increased operating costs.

- Q:Does the reservoir water heater press the booster pump (high marks)?

- The outlet water pressure of hot water is the same as that of cold water. The water heater is pushed by cold water to push out the hot water. (of heating). Installation location about 2 meters away from the ground, the impact of water pressure is not large, in rural areas, the installation position in more than two buildings will have an impact. In the city, the installation position is above four floor to affect the water pressure.

- Q:Why adjust the centrifugal pump outlet valve can adjust the flow? What are the advantages and disadvantages of this method? Is there any other way to regulate the flow of the pump?

- This method can be used to regulate flow. The advantage is that it is simple and easy to use and the disadvantage is that the throttle consumes energy

- Q:What are the reasons for sealing damage of centrifugal pumps?

- Three, water shortages caused by running dry grinding damage.This phenomenon is more common in mounted form inlet pressure, inlet air, air cavity pump, pump boot, high temperature operation of the mechanical seal friction at high speed, can not be cooled, check the mechanical seal, the spring tension is normal, the friction surface of charred black, rubber hard cracking.Treatment methods: exhaust the pipe and pump cavity air, replace the machine seal.Four, install too tight, observe the mechanical seal of dynamic and static ring plane, if there is serious burning phenomenon, flat black and deep traces, sealing rubber hardens, lose elasticity.This phenomenon is due to tight installation.Treatment methods: adjust the installation height, impeller installed, with a screwdriver to move the spring, the spring has a strong tension, release after the reset, there is 2-4mm moving distance can.

- Q:What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- Suction is allowed to pump the vacuum from the distance from the inlet, which is part of the field installation.The manufacturer of cavitation allowance is closely related to the design and process of pump. Estimation formula: cavitation allowance =10.33 meters - allow suction of -0.5 meters (safety).

- Q:What is cavitation, centrifugal pump cavitation phenomenon how to solve?

- Centrifugal pump cavitation phenomenon how to solve?:Measures to improve cavitation resistance of centrifugal pumps(1) improve the design of the suction port of the centrifugal pump to the impeller. Increase flow area; the radius of curvature increases the impeller cover inlet section, reduce the flow accelerated sharply with pressure; reduce the thickness of the blade, and the blade inlet rounded, close to the streamline, can also reduce the acceleration and pressure flow around the blade head portion of the impeller and the blade inlet part; improve surface finish in order to reduce the resistance loss; the blade inlet edge extends to the impeller inlet, the liquid flow in advance to accept work pressure, improve.

- Q:The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- 1. submersible pumpsA very wide range of water treatment tools. Unlike ordinary water pumps, it works underwater, while the pump works mostly on the ground.The working principle of submersible pumpBefore the pump is opened, the suction pipe and pump must be filled with liquid. Open the pump, the impeller rotating speed, which leaves the liquid together with the rotation under the action of centrifugal force, the left outside impeller injection, injection of the liquid in the pump shell gradually slow the spread of indoor speed, the pressure gradually increased, and then from the pump outlet, the outflow discharge tube. At this time, in the leaves at the center of the vacuum area of low pressure liquid was thrown to the surrounding formation there is no air and no liquid, liquid pool at the surface of the liquid under the action of atmospheric pressure, through the suction pipe into the pump, the liquid is continuously pumped up from the liquid pool is also continuously from the outflow discharge tube.Basic parameters of submersible pumpIncluding flow, lift, pump speed, matching power, rated current, efficiency, diameter and so onSubmersible pump main application and scope of applicationIncluding construction, construction, drainage, agricultural irrigation and drainage, industrial water recycling, urban and rural residents cited water supply, and even rescue, disaster relief and so on

- Q:Why can the centrifugal pump hold down the pressure?

- Centrifugal pumps are vertical, horizontal, single-stage, multi-stage, single suction, double suction, self suction and other forms. Vertical centrifugal pump is referred to as submerged pump, molten salt pump and submerged pump. Centrifugal pumps use the impeller to rotate and cause centrifugal motion of the water to work.

- Q:What are the ways of hydraulic pumps?

- There are several ways:Direct flow mode, such as external gear pump;Port plate, such as vane pump, axial piston pump, etc.;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Deep Well Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 35000台 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches