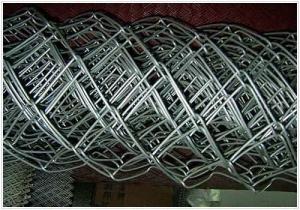

High Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

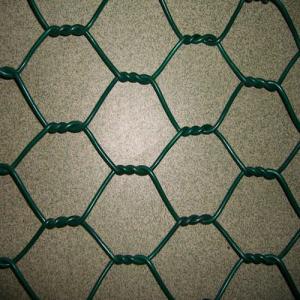

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q:What are the benefits of using steel wire mesh in the automotive industry?

- Using steel wire mesh in the automotive industry brings numerous advantages. Firstly, its high strength and durability make it perfect for reinforcing vehicle components, such as car seats, doors, and body panels, which ultimately enhances passenger safety. Secondly, steel wire mesh exhibits exceptional resistance to impact, corrosion, and wear, making it suitable for use in harsh environments. This makes it an ideal option for automotive applications that face various weather conditions and external forces. Furthermore, steel wire mesh provides excellent ventilation and airflow. This is particularly significant in the automotive industry as it regulates temperatures and prevents overheating of components like radiators and engine compartments, thereby improving overall vehicle performance and efficiency. Moreover, steel wire mesh offers design flexibility and versatility. It can be easily molded into different shapes and sizes, allowing customization and adaptation to specific automotive applications. This adaptability makes it compatible with various manufacturing processes, resulting in cost-effectiveness and efficiency. Additionally, steel wire mesh is lightweight compared to solid metal sheets, reducing the overall weight of vehicles. This weight reduction contributes to improved fuel efficiency and lower emissions, which align with the automotive industry's sustainability goals. Lastly, steel wire mesh is environmentally friendly. It can be recycled, enabling the reuse of scrap materials, reducing waste, and minimizing the environmental impact of the automotive industry. In conclusion, the use of steel wire mesh in the automotive industry offers numerous benefits, including high strength and durability, resistance to impact and corrosion, ventilation properties, design flexibility, lightweight nature, and environmental friendliness. These advantages make steel wire mesh an excellent choice for various automotive applications, contributing to improved safety, performance, efficiency, and sustainability.

- Q:What are the benefits of using steel wire mesh in the oil and gas industry?

- There are several benefits of using steel wire mesh in the oil and gas industry. Firstly, steel wire mesh offers high strength and durability, making it suitable for withstanding the harsh conditions and extreme temperatures typically found in oil and gas operations. Additionally, the mesh provides excellent corrosion resistance, ensuring a longer lifespan and reducing the need for frequent replacements. Steel wire mesh also offers excellent filtration capabilities, allowing for the removal of impurities and contaminants from fluids and gases, thus maintaining the quality and efficiency of the processes. Moreover, the mesh can be easily fabricated into various shapes and sizes, providing flexibility in design and installation. Overall, the use of steel wire mesh in the oil and gas industry enhances safety, efficiency, and cost-effectiveness in operations.

- Q:How does steel wire mesh perform in high-humidity environments?

- Steel wire mesh performs well in high-humidity environments due to its inherent properties and durability. Steel is known for its resistance to corrosion, making it a suitable material for applications in wet and humid conditions. The wire mesh is typically galvanized or coated with a protective layer, further enhancing its resistance to moisture and preventing rusting. In high-humidity environments, steel wire mesh maintains its structural integrity and strength. It does not warp, deform, or lose its shape, ensuring consistent performance over time. The mesh's open design allows for proper ventilation and airflow, preventing the accumulation of moisture that could lead to condensation or mold growth. Moreover, steel wire mesh is commonly used in various industries, including construction, agriculture, and manufacturing, where it is exposed to high humidity levels. It is often employed in concrete reinforcement, fencing, animal enclosures, and filtration systems, among other applications. While steel wire mesh is generally resilient in high-humidity environments, it is essential to select the appropriate grade and coating to suit the specific conditions. This ensures optimal performance and prolongs the lifespan of the mesh. Regular maintenance and cleaning should also be conducted to remove any accumulated debris or moisture, further preserving its functionality and appearance.

- Q:How is steel wire mesh used in the electronics industry?

- Steel wire mesh is commonly used in the electronics industry to provide a protective barrier for sensitive components. It is used as a shielding material to prevent electromagnetic interference (EMI) and radio frequency interference (RFI) from affecting the performance of electronic devices. Additionally, steel wire mesh is often utilized as a grounding element to dissipate static electricity and prevent electrostatic discharge (ESD) which can damage electronics.

- Q:What are the different wire materials available for steel wire mesh?

- There are several different wire materials available for steel wire mesh, each with its own unique properties and advantages. Some of the most common wire materials used in steel wire mesh include: 1. Stainless Steel: This is one of the most popular wire materials for steel wire mesh due to its excellent corrosion resistance, high strength, and durability. It is often used in applications where the mesh will be exposed to harsh environments or require hygienic properties, such as in food processing or marine industries. 2. Carbon Steel: Carbon steel wire mesh is known for its strength and affordability. It is commonly used in applications that require a strong and rigid mesh, such as construction, agriculture, and filtration. 3. Galvanized Steel: Galvanized steel wire mesh is coated with a layer of zinc to enhance its corrosion resistance. This type of wire mesh is particularly suitable for outdoor applications or environments where it may come into contact with moisture or chemicals. 4. Brass: Brass wire mesh is known for its excellent electrical conductivity, making it a popular choice for applications that require electromagnetic shielding or grounding, such as in electronics or telecommunications. 5. Bronze: Bronze wire mesh offers a combination of strength and corrosion resistance. It is often used in architectural and decorative applications, as well as in marine environments. 6. Copper: Copper wire mesh is highly conductive and has excellent thermal properties. It is commonly used in applications such as electromagnetic shielding, filtration, and insect screen. 7. Aluminum: Aluminum wire mesh is lightweight and has good corrosion resistance. It is often used in applications that require a lightweight and flexible mesh, such as in aerospace, automotive, or ventilation systems. These are just a few examples of the different wire materials available for steel wire mesh. The choice of wire material will depend on the specific application requirements, including factors such as corrosion resistance, strength, conductivity, and cost.

- Q:Is steel wire mesh suitable for use in automotive grilles?

- Indeed, automotive grilles can be effectively equipped with steel wire mesh. This robust and long-lasting material exhibits remarkable resilience against a wide range of environmental factors, such as high temperatures and impacts. By obstructing debris, insects, and other foreign objects from infiltrating the engine bay, it offers exemplary safeguarding for the vehicle's radiator and other crucial components. Moreover, steel wire mesh can be fashioned in diverse patterns and sizes, thereby elevating the visual allure of the vehicle's frontal appearance. Its adaptability and dependability render it a widely favored option for automotive grilles.

- Q:How does the mesh opening size affect the performance of steel wire mesh?

- The mesh opening size of steel wire mesh directly affects its performance. A smaller mesh opening size provides higher structural integrity and better support, making it suitable for applications that require strong and durable mesh, such as fencing or reinforcing concrete. On the other hand, a larger mesh opening size allows for increased visibility and airflow, making it more suitable for applications that prioritize ventilation or visibility, such as window screens or filtration systems. Ultimately, the mesh opening size should be chosen based on the specific requirements and intended use of the steel wire mesh.

- Q:Can steel wire mesh be used for security fencing?

- Yes, steel wire mesh can be used for security fencing. Steel wire mesh is a strong and durable material that provides excellent security and protection. It is commonly used for various security applications such as perimeter fencing, residential fencing, commercial fencing, and even high-security areas like prisons and military facilities. The strength and rigidity of steel wire mesh make it highly resistant to cutting or tampering, making it an effective deterrent against unauthorized access or intrusion. Additionally, the small openings in the mesh design provide visibility while still maintaining a high level of security. Steel wire mesh is also versatile and can be customized to suit specific security requirements. It can be easily installed in different configurations, heights, and thicknesses to meet the specific needs of any security fencing project. Moreover, steel wire mesh can be galvanized or coated with anti-corrosion materials to enhance its lifespan and withstand harsh weather conditions. In summary, steel wire mesh is a reliable and effective choice for security fencing due to its strength, durability, versatility, and resistance to tampering. It provides a secure barrier while still allowing visibility, making it a popular option for numerous security applications.

- Q:How does steel wire mesh compare to other types of wire mesh materials?

- Steel wire mesh is widely regarded as one of the most durable and versatile materials available for wire mesh applications. Compared to other types of wire mesh materials such as aluminum, copper, or stainless steel, steel wire mesh offers several distinct advantages. Firstly, steel wire mesh is incredibly strong and resistant to wear and tear. Its high tensile strength makes it suitable for a wide range of applications, including industrial, agricultural, construction, and even artistic purposes. It can withstand heavy loads, impact, and extreme weather conditions, making it a reliable and long-lasting option. Additionally, steel wire mesh is highly cost-effective. It is generally more affordable than other materials like stainless steel, while still providing similar levels of strength and durability. This makes it a popular choice for applications where budget considerations are important. Moreover, steel wire mesh is available in various sizes and gauges, allowing for customization to meet specific project requirements. It can be easily fabricated into different shapes and forms, making it adaptable for different applications. Whether it is used for fencing, reinforcement, filtration, or separation, steel wire mesh can be tailored to suit the needs of a particular project. Furthermore, steel wire mesh offers excellent corrosion resistance. It can be galvanized or coated with protective finishes to enhance its resistance to rust, ensuring its longevity even in harsh environments. This is particularly advantageous in outdoor or marine applications where exposure to moisture or corrosive substances is a concern. Overall, when compared to other types of wire mesh materials, steel wire mesh stands out for its exceptional strength, durability, cost-effectiveness, versatility, and corrosion resistance. It is a reliable choice for a wide range of applications, delivering superior performance and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords