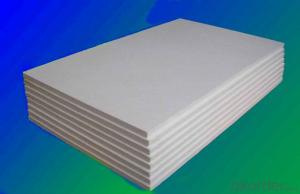

High Quality Ceramic Fibre Wool

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.industrial2.excellent thermal stability

3.high

4.fire proof

Aluminium-Silicate Wool

As one of the biggest suppliers on this business in China, in our own factory, we produce high quality aluminium silicate wool (also called ceramic wool) products

We can also produce the aluminium silicat wool with resistance tempreture capacity 1100'C, 1300'C, or up to 1700'C if client require.

The surface may be coated with metal mesh (single side, double sides), fiber glass cloth (single side, double sides, six sides), fiberglass blanket (single side, double sides), or aluminium foil (single side, double sides).

Specification and physical-chemical properties of Aluminium Silicate Wool fiber blankets

Type | GT-1 | GT-2 | GT-3 | GT-4 | GT-5 | |

Item | ||||||

Color | White | White | White | White | White | |

Diameter of fiber(µm) | 2~4 | 2~4 | 2~4 | 2~4 | 2~4 | |

Length (mm) | Arbitrary length | |||||

Width (mm) | ≤1200 | ≤1200 | ≤1200 | ≤1200 | ≤1200 | |

Thickness (mm) | 6~50 | 6~50 | 10~50 | 10~50 | 10~50 | |

Standard specification | 7200mmx600mmx20mm | |||||

Working temperature () | 1000 | 1100 | 1200 | 1250 | 1350 | |

Max·working temperature() | 1250 | 1260 | 1350 | 1400 | 1450 | |

Bulk density (±10%) | kg/m3 | 9612816092 | 96128160192224 | |||

(pcf) | 681012 | 68101214 | ||||

Tesile strength | (Mpa) | 0.04 | 0.04 | 0.03 | 0.03 | 0.03 |

(psi) | 7 | 7 | 5 | 5 | 5 | |

Thermal shrinkage for 24hrs (%) | 1150 | 1250 | 1300 | 1300 | 1350 | |

Thermal conductivity | 128kg/m3 or 8pcf | 800 0.15 | 800 0.15 | 1000 0.18 | 1000 0.18 | 1000 0.18 |

1000 0.17 | 1000 0.18 | 1200 0.26 | 1200 0.26 | 1200 0.31 | ||

160kg/m3 or 10pcf) | 800 0.14 | 800 0.13 | 1000 0.17 | 1000 0.17 | 1000 0.121 | |

1000 0.16 | 1000 0.17 | 1200 0.24 | 1200 0.24 | 1200 0.30 | ||

AL2O3(%) | 45~47 | 47~54 | >54 | >54 | 38~54 | |

SiO2(%) | 52~54 | 45~52 | 45 | 45 | 35~45 | |

ZrO2(%) |

|

|

|

|

| |

Fe2O3(%) | <0.4 | <0.3 | <0.2 | <0.2 | <0.2 | |

K2O+Na2O(%) | <0.3 | <0.3 | <0.2 | <0.2 | <0.2 | |

CaO+MgO(%) | <0.2 | <0.2 | <0.2 | <0.2 | <0.2 | |

FACTORY:

- Q:What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q:What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q:What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q:How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board divided by density, can be divided into ceramic fiber, ceramic fiber board density 250-260Kg/m fand; density, fand 300-350Kg/m;

- Q:Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Volume density is low: the density of the ceramic fiber lining is about 25% of the lining of the light heat insulation brick, about 10% of the lining of the light pouring material; adopting the fiber lining can greatly reduce the steel structure load of the furnace and prolong the service life of the furnace lining.

- Q:What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q:What are the sound-absorbing fiber boards?

- Sound-absorbing material:1, itself has sound-absorbing properties, porous fiber material.2, does not have sound-absorbing material, but processed into sound absorption structure.Common sound-absorbing materials are: polyester fiber sound-absorbing board, trough wood sound absorption board, hole wood sound-absorbing board, recycled wood sound-absorbing board, the latest is Dr. sound, high temperature ceramic sound-absorbing board, a fire prevention, water quality, hard environmental protection

- Q:What are the standards for ceramic fiber boards?

- Ceramic fiber board currently only GB, and many production enterprises are also in accordance with GB to perform.

- Q:Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q:Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Ceramic fiber boardCeramic fiber board product categories:1260 standard ceramic fiber board sygx-264 1260 high purity ceramic fiber board sygx-3641400 zirconium ceramic fiber board sygx-564 1400 high alumina ceramic fiber fire plate sygx-464D1400 zirconium ceramic fiber fire baffle sygx-564D

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Ceramic Fibre Wool

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords