High Quality Cement Polypropylene Fibers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

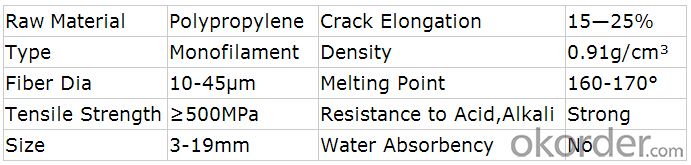

1,Specification of High Quality Cement Polypropylene Fibers

2,Introduction of High Quality Cement Polypropylene Fibers

Polypropylene fiber is also called engineering fiber, concrete fiber, anti-cracking fiber,synthetic fiber or plastic fiber.

We use high tenacity polypropylene resin as the raw material and produce with special technics. Putting the pp fiber into concrete or mortar can control the microcrack caused by such factors as the plasticity contraction, air shrinkage and temperature change. Great prevention of cracks-being, improvement of the features of anti-cracks and permeation-resistance, shock and earthquake proof, all these have been good evidence for the wide usage of pp fiber--finish coat of road and bridge, mining and tunnel construction, railroad, high-rise building, consolidation of side, fire-protection infrastructure, concrete-mending, industrial civil use engineering, wall, basement, waterproof project of pool and roof garden, kinds of prefabricate concrete products etc.

3, Package of PP Staple fiber

1kg/plastic bag, 20pastic bags/woven bag.

1x20' QTY: 9-10 Tons

1x40HQ QTY: 22-23Tons

allowing more or less clause.

4, Images of the Fiber

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP related product that used as the raw material of textile, automotive interior and constuction projects etc. Have been in this field for many years, with rich experience.

2> What's the MOQ?

1x20'GP or1x40'HQ will be better as the price would be economical based on full container load.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q:What's the difference between Oxford fabric and polyester fiber?

- Oxford cloth, also known as Oxford spinning, namely nylon Oxford, also known as nylon Oxford cloth, or nylon, also known as nylon, nylon, scientific name polyamide.(later synthetic polyester Oxford)Polyester fiber is 100% pure polyester fiber! The scientific name for polyester fiber is polyethylene terephthalate (ethylene terephthalate), referred to as polyester.

- Q:How to make fiber streamline test for forging parts?

- Acid corrosion prevention method: A. neutralization: soak in 10% ammonia solution and rinse with hot water. B. passivation method: immerse concentrated nitric acid for 5 seconds, then rinse with hot water. C. coating protection: coated with varnish and plastic film.

- Q:What are polyester fibers and washing methods?

- Polyesters come from Phthalic Acid and two lactone, or glycol, usually ethylene glycol, esterified and condensed. In fact, internal transesterification is carried out with two benzoic acid, two methyl ester. When the methanol recovery, the molten polymer will stretch forming fiber. In order to obtain high transparency and luster fibers, some monomers are added to the melt. In order to obtain low crystallinity and low strength products, part of stretch yarn, and then further stretch, textile and plastic. Polyester fiber near the glass transition temperatures near the stretch and textile can get very high degree of crystallinity, the high crystallinity and leads to high strength, resulting in two small molecular dimer or very fine thread. The surface of polyester fiber is hydrophobic.In further treatment, the crystallinity of the polymer is also important, and any heating near the glass temperature will reduce the crystallinity, thereby reducing the mechanical properties of the fiber.

- Q:What is blended spinning fabric?

- Blended fabric is cotton, chemical fiber and other silk, hemp textile products of natural fiber blended yarn fabric. For example: polyester cotton, polyester wool gabardine etc..

- Q:Nylon taffeta and polyester fiber which wear

- Polyester fiber polyester is called two not good compared directly, rather than comparing you with polyester 600D Oxford cloth and 400T nylon taffeta, polyester Oxford it is certainly more resistant; similarly, nylon Oxford cloth to wear than 400T polyester pongee.

- Q:What are man-made fibers? What are his strengths and weaknesses?

- Synthetic fiber has similar properties as natural fibers. It has good moisture absorption, air permeability and dyeing properties. It is soft and lustrous. It is an important textile material. It can be spun or blended with natural fibers such as wool and silk and synthetic fibers. Viscose fiber in the high strength because of high strength, good resistance to many times deformation, can be used in industry. Regenerated protein fiber having a property similar to wool and used as a substitute for wool. Proteins can be grafted, copolymerized or blended with other fibers to improve the properties of other fibers. In 1984, man-made fiber production was about 3.1Mt, accounting for 21.3% of total chemical fiber output.

- Q:What do you mean by "T300 T700" in carbon fiber?

- T300 and "T700" refer to the grades of carbon fibers, usually measured by tensile strength. T300 tensile strength should reach 3.5Gpa; T700 tensile should reach 4.9Gpa. At present, only 12K carbon fiber can reach the T700 level.

- Q:40%PU 60% polyester fiber?

- High grade polyester fiber material that is much more durable than cotton and silk products, but the cost is very high. PU artificial leather is the same reason, high-end PU can use recycled waste leather, after crushing, high-pressure punching and other steps refurbished, good workmanship completely genuine, more durable than leather.

- Q:Are polyester fiber or spandex fiber or fiber?

- Polyester fiber and spandex belong to chemical fiber or fiber.Chemical fiber usually refers to chemical fiber.Chemical fiber is made of natural macromolecule compound or synthetic macromolecule compound, which is prepared by spinning, dope, spinning and post-treatment.

- Q:What about polyester fabric? How about air permeability?

- Polyester fiber generally refers to polyester fiber, fabric quality is the result of comprehensive performance, as outlined below, your question is only the last line to answer, but I think you need to know something:The main physical and chemical properties of polyester fiber1. form: Polyester vertical surface straight, smooth, cross section is round (can be changed to special-shaped, such as triangle, hexagon, etc.). Polyester acid and not alkali, because polyester macromolecules in the ester base in the hydrolysis, but also can use appropriate alkali for polyester silk imitation treatment. (alkali reduction treatment)2., stretch and flexibility: polyester high strength, stretch growth, resilience, good, ordinary polyester strength of 35.2 ~ 52.8cN/tex, breaking elongation rate of 30% to 40%. According to the different processing, polyester has high strength, low extension, low strength, high extension and so on. Because of its high strength, great elasticity and good elasticity, polyester fiber has good wear resistance, which is second only to nylon. In addition, the high modulus polyester fabric, so crisp, good dimensional stability.3. moisture absorption and dyeing: Polyester structure close, high crystallinity, internal macromolecules without hydrophilic gene, so low moisture absorption, dyeing difficult. Polyester in general atmospheric conditions, moisture regain is only 0.4%. Therefore, the fabric has the advantages of easy washing and quick drying, and also reflects the defects of poor sweat absorption and poor ventilation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Cement Polypropylene Fibers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords