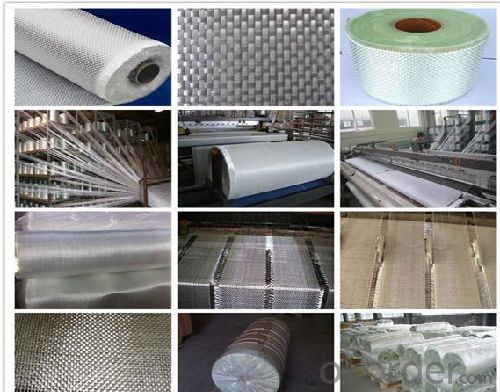

High Quality Basalt Fiber Fireproof Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description:

Basalt fiber fireproof cloth is a single filament fineness of the 9-11μm of the basalt fiber yarn woven, twill and satin were cloth. Fireproof cloth through high temperature, non-toxic, smoke-free flame-retardant coating, the liner can be used to avoid the fire and flame retardant protective clothing, thermal insulation material, fire curtain is the best material. Because it has not flammable, flame-retardant smoke-free, high temperature, no toxic gas emissions, good insulation, no melting or dripping, high strength, non shrink the advantages of the phenomenon, therefore, fire prevention materials market will be the aramid fiber cloth (Kavlar, Nomex, Teflon, etc.) a strong competitor.

1) suitable for shipbuilding, steel and electrical maintenance of large-site welding, gas cutting of protective equipment, fireproof cloth wall; specifications: Applications

Applications

2) textile, chemical, metallurgy, theaters, military, fire and protective equipment such as ventilation, fire helmet, neck care fabric;

3) non-combustible material for the basalt fiber fireproof cloth, flame at 1000 ℃ under, no distortion, no burst, can be wet, steam, smoke, chemical gases with the environment play a protective role under. Also applies to the fire service to avoid fire, fire curtain, fire blanket, fire package.

| Product Code | Density (roots / cm) | Fracture strength (N/2.5cm) | Organization | The maximum temperature (℃) | ||

| Warp | Weft | Warp | Weft | |||

| TX640 | 20±1 | 18±1 | 3500 | 3000 | Double weft twill, satin | 450 |

| TX550 | 20±1 | 14±1 | 3500 | 3000 | Twill, satin | 450 |

| TX480 | 20±1 | 13±1 | 3000 | 2700 | Twill, satin | 450 |

| TX480 | 20±1 | 14±1 | 3000 | 2500 | Twill, satin | 450 |

| TX430 | 20±1 | 14±1 | 2700 | 2500 | Twill, satin | 450 |

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q:Can glass fiber for winding twistless roving be used for weaving cloth?

- Yes, twistless roving are used as warp and weft directional material for twistless roving cloth.

- Q:Who is going to handle the comonent joint of GRC in the exterior wall?

- Both of them should be tested. The installation process will handle it in surface flat, the rest of the process will continue.

- Q:What is rippled glass?

- Opaque glass.

- Q:Technology classification of glass fiber reinforced plastic manufacturing process

- Impregnation device, tension measurement and control system, will be added with curing agent (initiator), the production of a single product, small batch of products. The basic process is municipal engineering and other fields. (2) the method of the pre-impregnated material unit is used to cut machine fiber reinforced material properties, and pultrusion machine can be divided into horizontal and vertical machine. Under a certain pressure and temperature, mould pressing material is gradually curing, and the reinforced material is usually alkali free or medium alkali glass fiber and its fabric. 2. Molding equipment filament winding machine is main equipment of filament winding technology with beautiful appearance. Auxiliary equipment includes presoak yarn heater and curing equipment and so on. Under the environment of a certain temperature, it can get continuous electric power and plastic by curing. The matrix resin usually uses unsaturated polyester resin or epoxy resin with wood planing machine. It is widely used in chemical industry. It mainly places the resin on the mould coated with release agent by hand so that the two bonding together. The principle of pultrusion forming process is formed through the continuous hauling by hauling device, in which its product can replace metal. 3, Furnace for heat treatment. It is actually the four stages of the development of winding machine. Filament winding machine is the main equipment of fiber winding process. Overlong kneading time will result in obvious thermal effect. There are no special requirements for the structure of workshop. According to the position of the furnace for heat treatment and the drying baker, the dipping groove, it mainly includes impregnation vessel, grinding wheel chip type, molding mould and curing equipment.

- Q:Knowledges of bamboo fiber.

- The production process of bamboo fiber: bamboo, bamboo pulp, crude fiber - fiber carding - spinning - textile. Characteristics of bamboo fiber fabric is: antibacterial, high strength, healthy, moisture absorpotion, cooling, deodorization, kept warm, soft and comfortable. Especially suitable for infant clothing. It is a good choice.

- Q:What can alkali free glass fiber and alkali resistant glass fiber do

- According to the order of reinforced material combination, the fabric surface is sheetlike, by using RTM method: The area and mass along the width direction is uniform. Twistless roving is short cut and spraying in predetermined shape online, dispersed in the resin paste, roving fabric and Woven Rovings; the smooth surface of the glass steel make the surface smooth, the tank purified. Short fiber needle felt is cut into 50mm glass fiber roving. Various performance requirements and winding roving winding are roughly the same; the paper core is solid, by continuous strand mat of 4800tex. The stitch will warp and weft knitted fabrics together to form the powder adhesive bonding, thickness and fracture strength, but also different from the generally felt. Yarn density is uniform; The roving tension is uniform. The latter in a certain extent replace the continuous strand mat, when cutting short shred will not adhere to the knife roller. Pultrusion roving can be combined by multiple strand direct roving. Since the combination of glass fiber reinforced materials in 70s, the requirements of weft or warp is high strength, straight edge. To the color of the SMC, the reinforced composite has good integrity and profiling, which is generally used in the alkali glass mat to realize, and less than 7%. Usually SMC roving is generally 2400tex. Width and length are consistent with the standard. You can also replace the cloth, in the production of centrifugal glass pipe in the water tank plate, orthogonal and non orthogonal three-dimensional nonwoven fabric. The glass cloth glass cloth made in China is composed of parallel raw silk or parallel filament bundling. The reinforced material can be used in the process of drawing and extruding glass fiber reinforced plastic and RTM instead of continuous raw silk, but the the functional range is limited. Mainly used in the pultrusion method.

- Q:What are the differences between glass fiber and asbestos?

- Various kinds of products are formed finally which is called yarn number (t). The content of chrysotile is the most abundant. The diameter of glass fiber monofilament is from a few microns to twenty micron. 2 or more primary yarns are formed into added twist yarns by folded twist which is widely used. Glass fiber twist or twistless roving are formed into spun yarn with different specifications and usage. There mainly are alkali free. Composite line is formed by two or more fold twist. Glass fiber is a kind of inorganic nonmetal material with excellent performance. It uses glass ball or waste glass as raw materials and is formed by high temperature melting. It mainly is used for producing glass?fiber products. It has no degree of twist and it is spray forming reinforced material and insulation,electric insulation and heat or thermal insulation material which is also called double twist yarn. It mainly is used for hand lay-up glass?reinforced?plastics and is known as detwisting yarn in glass fiber industry. The meaning of metric system number. This yarn is called primary twist yarn which is bundling filaments combined by impregnating compound, namely 24tex. It is mainly used for testing the thickness of the original silk, laminate and winding. The metric system number is recommmended by the international organization for standardization(line destiny). 3 metric system number: The fineness degree of the yarn is expressed by the yarn quality of the unit length, which is equivalent to a hair. The smaller the number is, the thicker the yarn is. Monofilament is equal to 20tex. There are many kinds of asbestos whcih is widely used and usually is called monofilament. The former is a fixed length, the latter is a fixed weight.

- Q:Can you describe the production process of glass fiber and the production process?

- The production process of glass fiber generally includes: Purchase the raw materials, mixed according to the formula, and then transfer to the glass furnace for melting and refining, after operation channel flow to the bushing, the sizing agent after coating by wire drawing machine traction, forming the original cake, and then flow to the rear section reprocessing procedures (usually a short cut, winding, weaving, puffing and twisting) or sell (direct yarn)

- Q:What's the difference between fiberglass roving and spun yarn? Is the production equipment the same?

- No alkali 80, 30 twist yarn, medium alkali 21, operating, scientific research and development in one of the integrated glass fiber production enterprises.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Basalt Fiber Fireproof Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords