High Quality AR Glass Fiber Chopped Strand- Zirconia 16.5%

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of AR Glass Fiber Chopped Strand- Zirconia 16.5%:

AR glassfiber is one kind of concrete fiber used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Technical Data of AR Glass Fiber Chopped Strand- Zirconia 16.5%:

PRODUCT NAME | AR- FIBERGLASS CHOPPED STRAND | |||

TEST CRITERION | JC/T572-2002 | |||

TEST ITEM | METERAGE UNIT | STANDARD | RESULT | CONCLUSION |

ZRO2CONTENT | % | ≥16.5 | 16.7 | MEASURE UP |

MOISTURE CONTENT | % | ≤0.2 | 0.1 | MEASURE UP |

TENSILEBREAKING STRENGTH | N/TEX | ≥0.25 | 0.3 | MEASURE UP |

CHOPPED LENGTH | MM | 12±1 | 12 | MEASURE UP |

LINEAR DENSITY | TEX | 98±8 | 99 | MEASURE UP |

COMBUSTIBLE MATTER CONTENT | % | 0.8-2.0 | 1.48 | MEASURE UP |

CONCLUSION | IN CONPLIANCE WITH JC/T572-2002 | |||

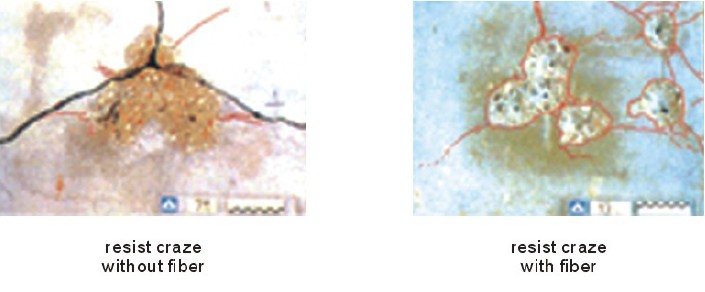

Crack Test:

- Q:What is better brick patio or cement patio(ie cleaning it,cost)?

- Snowman obviously doesnt know how to pour concrete. Concrete is easier, brick looks better EDIT: if you dig your footings, add enough rebar and it's the right size(the rebar), it wont crack.

- Q:My aunt found a kitten and she was COVERED in cement. We took some off because it was eating her skin or something like that. But whats a faster way to get if off or loosen it to make it easier...Please help!

- you should def. consider a vet visit. sometimes you can even find a vet that will do a free 1st examination and then find out how much it will cost you for them to get this cement off. but you should def. go soon before the cats skin is damaged even more.

- Q:i'm replacing my tub area wall with cement backerboard. how do i butt the backerboard end with the textured drywall end? and how can i remove the old drywall joints (the area with the joint tape)? that's where i will butt the concrete backerboard.

- use the same nylon joint tape and the thinset that you used on the other joints of the backerboard. aplly the thinset as smooth as possible. when it dry you can apply a layer of drywall joint compound over the thinset. you dont have to over lap the tile over the joint. after the drywall compound dries, sand and finish like the rest of the drywall

- Q:I am starting a project and I would really just like to know the properties of rubber cement. If you put it in mold and left it to dry would it be flexible or stiff or would it even retain that formation? Would it then break easily? I know it seems like a stupid question, but I really have no experience with the stuff. Please help, thanks.

- look under the large category called MAKING MOLDS YOURSELF--many of those materials can be used to make molds themselves, or to make casts in molds .

- Q:I have a small nick on my tire, and just a small piece of rubber is hanging out. There is no air coming out and the cords or anything is not showing, don't be alarmed. I've driven around with this car and nothing has happened. It just cut the top portion of the tire, not so deep where any major damage is visible. I'm afraid to just rip the little piece off. Can I use rubber cement glue to glue the little piece back together?Once again, there is no major damage to the tire. No air coming out or cords showing. Just a slight tear.

- Correct. Can we please no longer make a bunch of assumptions? Try slightly curiosity before y'all believe you know what is going on on. I am within the equal situation. This hose for my auto shouldn't be on hand new, and it have got to be patched, or I need to scour the continent for junk-yards with the hose still in the automobile. Thanks hyper-dog. Good suggestions. I'm additionally wondering if A bicycle-tire variety patch package would work. The oven scan is as a rule a excellent one.

- Q:ive just got my braces fitted today, and at the back of my mouth i have some cement to stop me biting hard and breaking my braces. The problem is i find this cement really uncomfortable. will the cement wear down a bit ? or i will i get used to it? please help x

- often what they could use whilst they clean and descale your tooth, besides the very indisputable fact that sometimes they hire a ultrasonic drill or typical dental drill (it relies upon on your ortho). Mine used a ultrasonic drill to take the the remainder of, and then (once I asked it) he gave my tooth a stable clean and descale. there will be in basic terms a sprint left on each and every tooth whilst they're complete (they are able to't clean all of it off in concern of unfavorable the rather tooth) yet that wears away over the years with the aid of usual daily tooth brushing.

- Q:hellow I gutted my bathroom all the wall board and I put up cement backerboard and want to know what I can use on the seams I have the fiberglass mesh tape , Joint compound is for wall board grout is for tile . Cement ? plaster ? I want it waterproof hydrolic cement ?Any help With this I would really appreciate.I'am an electrician not a wall trade and i want it to be right , from the jump. Thanks g, Singh

- Remember that when you tile to use 100% silicone in the corners and along the bottom edge before grouting. Let it cure a couple days. This will prevent any grout from getting into those joints. I also used red guard on the seams and joints of the backer board.

- Q:Let's see if I can get the right. I have 12 cement columns which are three meters high (on third floor) and I want to put wooden columns on top of them 3 meters high. (fourth floor) The trusses will be on top of the wooden column. I'm concerned about how to connect the wooden columns to the cement columns so that they are stable and secure?

- If the wooden columns are square and a standard size, use a bracket designed for deck construction. They are made of galvanized sheet steel and are bolted down to the concrete in the center. Look into an epoxy product (maybe 3M) that will allow you to use a stud to hold the steel bracket in the concrete. Often, cracks occur in a narrow column if an old fashioned lag anchor or lag type stud is used.

- Q:how does sediment compact or cement into sedimentary rocks?

- Just speaking to sediments in general. Sediments become sedimentary rocks by one of two mechanisms -- cementation and compression. Cements “glue” one particle to another and commonly include: (1) calcite (CaCO3) (2) silica (SiO2) (3) limonite (Fe2O3) (4) hematite (Fe2O3.xH2O) Water flowing through certain sediments becomes supersaturated with calcite or silica. When this water evaporates, these dissolved minerals precipitate around the grains through which they flow. Over time, the precipitation of these cements overlaps, binding one grain to another. But the case of hematite and limonite cements is a little different. Iron occurs in solution in its ferrous (Fe+2) state. When ferrous iron encounters oxygen, it oxidizes into its ferric (Fe+3) state, which is insoluble. This ferric iron precipitates, coating the grains through which it flows with either hematite or limonite. It coats the grains, eventually binding one grain to the next. Sedimentary rocks commonly cemented include conglomerates, sandstones, evaporates, ironstones, as well as some limestones, some cherts, and some phosphorites. This process of cementation involves heat that allowed these fluids to exist and flow, but not so much as to cause a metamorphic rock to be created. Compression involves finer grained sediments. Clay, organic matter, lime mud, and phosphorite mud, once buried, are subjected to progressively more overburden. The thickness of these layers is significantly reduced as water is “squeezed” out. These fine particles have very high surface areas and surface charges causing these grains attach to one another. In addition, surface irregularities become intertwined, holding grains together. Sedimentary rocks that are formed from sediments by compression include shale and coal as well as some limestones, some cherts, and some phosphorites.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality AR Glass Fiber Chopped Strand- Zirconia 16.5%

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords