High Quality and Good Price Grinding Rod with Dia 30mm-300mm Used in Rod Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

1. Specifications of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

Diameter: 30mm--300mm, or as customer's requirement

Length:2m-12m, or as customer's requirement

Application: mainly used in the rod mill. The detailed fields are: Mining Ores, Cement, Chemical Factory, Coal-powered plant,quartzs and so on.

Package: By bundle, or as customer's requirement

2.Chemical Composition of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

Material | C | Si | Mn | Cr | Cu | Mo | P | S |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | 0.25 | 0.25 | 0.3 | | |

50Mn | 0.48-0.56 | 0.17-0.37 | 0.7-1.0 | 0.25 | 0.25 | 0.3 | | |

60Mn | 0.57-0.65 | 0.17-0.37 | 0.7-1.0 | 0.25 | 0.25 | 0.3 | | |

65Mn | 0.62-0.70 | 0.17-0.37 | 0.9-1.0 | 0.25 | 0.25 | 0.3 | | |

RCBA-1 | 0.52-0.65 | 0.17-0.37 | 0.6-1.2 | ≤0.25 | | | ≤0.035 | ≤0.035 |

RCBA-2 | 0.5-0.8 | 0.17-0.37 | 0.6-0.8 | 0.9-1.1 | | | ≤0.035 | ≤0.035 |

RCBA-3 | 0.72-0.92 | 0.17-0.37 | 0.7-1.0 | 0.5-0.9 | | | ≤0.035 | ≤0.035 |

3.Properties and Microstructure of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

material | diameter | length | hardness | metallurgical structure |

45# | 30-300mm | 2-12m | ≥45 | M+C |

50Mn | 30-300mm | 2-12m | ≥50 | M+C |

60Mn | 30-300mm | 2-12m | ≥55 | M+C |

65Mn | 30-300mm | 2-12m | ≥55 | M+C |

RCBA-1 | 30-300mm | 2-12m | ≥50 | M+C |

RCBA-2 | 30-300mm | 2-12m | ≥55 | M+C |

RCBA-3 | 30-300mm | 2-12m | ≥55 | M+C |

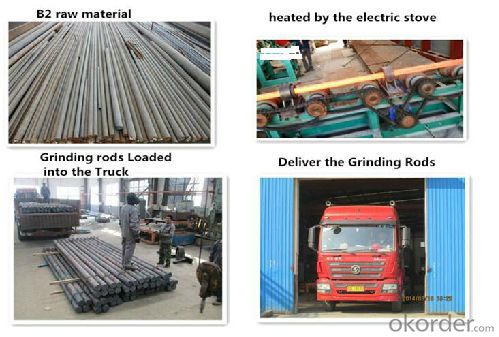

4.Production Process of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

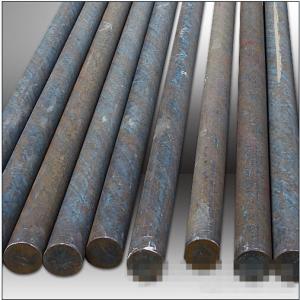

5.Some Photos of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

- Q:Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- uch as: automobile transmission shaft adopts mechanical rolling machine with good performance, gray cast iron can play seismic effect effectively, with good thermal conductivity of radiator graphite in gray cast iron, the aircraft engine turbine blade by casting directional solidification casting and Dan Jingzhu.Do everything we can to make the best use of it, the advantages and disadvantages of rolling and casting, and you'll find it yourself, Baidu, depending on how you use it

- Q:What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q:What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q:How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q:What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q:Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good.

- Q:Why does the surface of stainless steel casting mirror mirror ripple?

- Because the grinding machine is layer by layer. And the material inside the casting is not completely uniform.

- Q:Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q:What are the general technical requirements for casting parts?

- No matter what kind of material casting, there are the following major requirements:Material requirements. Mainly hardness, tensile strength, elongation, impact toughness.Two, dimensional accuracy and shape accuracy. Different castings have different requirements. Different sizes and geometric tolerances and different tolerances are adopted.Three, according to the use requirements, the casting of other defects, acceptance requirements. Such as holes, sand holes, shrinkage, slag, sand, crack.........Four. Requirements for defect repair.

- Q:There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

1. Manufacturer Overview |

|

|---|---|

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

High Quality and Good Price Grinding Rod with Dia 30mm-300mm Used in Rod Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords