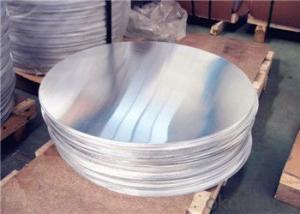

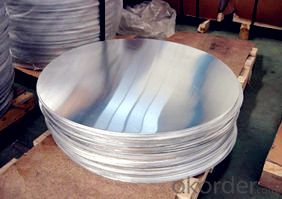

High Quality Aluminum Wafer with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Wafer

Aluminum Wafer Description

Aluminum wafers are widely used in electronics, cosmetic, medicine, culture and education and auto parts. Electrical appliances,heat preservation,machinery manufacturing,automotive, aerospace,military, mold,construction,printing and other industries. Such as kitchen utensils such as non-stick pan,pressure cookers and other hardware supplies such as shades,water heaters shell,is the largest amount of aluminum alloy strip deep processing of one of the products.

Aluminum Wafer Production Methods

Punch processing

1. Rough material cut (cut into a square)

2. Blank (punching into the Aluminum discs you want)

If it is a roll material, it is necessary to open the material.

Aluminum Wafer Alloy state

Main series: 1 series, 3 series, 5 series, 6 series, 8 series is in the majority.

State : O, H ;

Aluminum Wafer Packaging

Technical Features of Aluminum Wafers Production Line

1. NC automatic, the production line from the coil from the volume, until the whole roll material to complete the middle of the material does not require manual contact with any material, do not need any adjustment, fundamentally put an end to the ordinary punch punch production safety risks and Product quality hidden.

2. The line can use the coil directly to the wafer production, do not need to roll the material slitting and cross-cutting treatment, reducing the production process, reducing the cost of production and reduce the damage to the surface of the material may be produced Wafer to ensure that no oil, no scratches.

3. The line full use of the width of the coil, the use of high-precision servo motor drive system control, so that the wafer spacing and wafer to the material edge of the distance to a minimum, fundamentally reduce the amount of waste, raw material utilization rate of 80% the above.

4. The production rate can reach 40-55 per minute, to improve the production efficiency.

5.Due to the use of modular mold design, when the conversion of wafer production specifications, the conversion time can be reduced to 15 minutes or less. The diameter of the wafer that can be produced ranges from 85 mm to 750 mm.

6. Advanced open system, six heavy leveling machine, high rigidity of the mechanical presses, automatic palletizing system, to ensure that the wafer products of high quality.

Introduction of our company

Our company is one of the largest aluminum cookware producer in China, and we have produced aluminium circles over 20years, our aluminum circles could be good quality for cookware deep drawing and spinning dawing usage.

Also we are the professional Aluminium Strip manufacturer and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,Aluminum Strip, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container etc. series of aluminum products, sincerely welcome everyone to visit.

- Q:Does the profiled bar include aluminum profiles? What are the differences between aluminum and profile?

- In fact, profile and profile now in concept, there is not much difference. Special non conventional means. In fact, the conventional shape shape materials generally have a special name: like bar, sheet, pipe, wire rod, angle, elliptical material and so on. So that the profile is actually refers to the profile.

- Q:The aluminum and Fenglv aluminum material which is better suited for doors and windows

- Al Feng is one of the ten famous material, certainly no problem. But Feng packaging is too thick, high cost. To do the doors and windows of the aluminum used to choose cost-effective, as a special material for the sale of aluminum, I have the following recommendations: 1. The window wheel is good, and the pressed glass should be durable and corrosion resistant. 2. doors and windows sealing performance better, 3. pages to be matched with materials, gauze or rust, and thickness and density better than 4. The cost performance is high, the surface treatment layer of the profile is electrophoresis, and the electrophoresis layer should be thick. 5. The mounting frame needs to be hit to the horizontal line.

- Q:What are the different shapes available in aluminum profiles?

- There are various shapes available in aluminum profiles, each designed to serve specific purposes and meet different structural requirements. Some common shapes include: 1. T-shape: This profile has a T-shaped cross-section, with a horizontal section and a vertical section. It is often used to create joints, connections, or support structures. 2. U-shape: This profile has a U-shaped cross-section, with two parallel sides and an open bottom. It is commonly used for framing, edging, or as a protective barrier. 3. L-shape: As the name suggests, this profile has an L-shaped cross-section, with one side longer than the other. It is frequently used for corner brackets, supports, or to create right-angle connections. 4. Square shape: These profiles have a square cross-section, with all sides equal in length. Square profiles are versatile and can be used for a wide range of applications, such as framing, rails, or supports. 5. Round shape: This profile has a circular cross-section, making it ideal for applications that require rounded edges or a seamless look. It is commonly used for handrails, decorative purposes, or in the automotive industry. 6. Rectangular shape: These profiles have a rectangular cross-section, with two longer sides and two shorter sides. They are often utilized for structural framing, supports, or as beams. 7. I-beam shape: Also known as an H-beam, this profile has an I-shaped cross-section with a central vertical web and two horizontal flanges. I-beams offer excellent strength and are commonly used in construction, bridges, or industrial applications. 8. Channel shape: This profile has a U-shaped cross-section with one side shorter than the other. It is widely used for structural support, framing, or as tracks for sliding doors and windows. These are just a few examples of the various shapes available in aluminum profiles. The choice of shape depends on the specific requirements of the project, such as load-bearing capacity, design aesthetics, or functionality.

- Q:How do aluminum profiles perform in vibration isolation applications?

- Due to their unique properties and characteristics, aluminum profiles prove to be highly effective in applications involving vibration isolation. The utilization of aluminum profiles in such scenarios aids in the reduction and mitigation of vibrations, thereby establishing a stable and isolated setting. The high strength-to-weight ratio of aluminum profiles stands as one of the primary factors contributing to their efficacy in vibration isolation. Aluminum, being a lightweight material, enables the construction of structures capable of efficiently absorbing and dissipating vibrations. This lightweight nature ensures that the profiles do not add excessive weight to the system, as doing so could amplify vibrations instead of dampening them. Furthermore, aluminum profiles exhibit exceptional damping capabilities. Damping refers to a material's ability to absorb and dissipate energy from vibrations. Aluminum inherently possesses damping properties, which play a significant role in diminishing vibration levels. As a result, the profiles effectively isolate vibrations and prevent their transmission to other components or structures. In addition, aluminum profiles can be easily customized and designed to meet specific requirements regarding vibration isolation. Engineers can tailor the profiles' geometries and configurations to effectively attenuate vibrations. This design flexibility permits the optimization of profiles for diverse applications and environments, ensuring maximum effectiveness in vibration isolation. Moreover, aluminum profiles offer commendable corrosion resistance, a crucial factor in vibration isolation applications exposed to harsh operating conditions. This resistance to corrosion guarantees the durability and reliability of the profiles, maintaining their performance over extended periods. In conclusion, due to their lightweight nature, excellent damping capabilities, customization options, and corrosion resistance, aluminum profiles prove to be highly suitable for vibration isolation applications. Through their efficient absorption and dissipation of vibrations, aluminum profiles enable the creation of stable and isolated environments, effectively minimizing the impact of vibrations on surrounding components or structures.

- Q:Can aluminum profiles be used for partitions and dividers?

- Yes, aluminum profiles can be used for partitions and dividers. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an excellent choice for such applications. Aluminum profiles can be easily fabricated and customized to create various partition and divider designs, including room dividers, office partitions, and retail space separators. They can be used in both residential and commercial settings to create functional and aesthetically pleasing spaces. The use of aluminum profiles for partitions and dividers also allows for easy installation, maintenance, and future modifications if needed.

- Q:How do aluminum profiles contribute to sustainable infrastructure development?

- Aluminum profiles contribute to sustainable infrastructure development through their numerous environmental benefits. Firstly, aluminum is a highly recyclable material, with over 75% of all aluminum ever produced still in use today. This promotes a circular economy and reduces the need for primary aluminum production, which requires significant energy consumption and releases greenhouse gas emissions. Additionally, aluminum profiles are lightweight yet strong, allowing for efficient transportation and installation, which reduces energy consumption during construction. Furthermore, aluminum's corrosion resistance ensures the longevity of infrastructure, reducing maintenance and replacement needs. Overall, the use of aluminum profiles in infrastructure projects promotes sustainability by minimizing resource depletion, reducing energy consumption, and extending the lifespan of structures.

- Q:Can aluminum profiles be used for DIY projects or home improvement?

- Yes, aluminum profiles can be used for DIY projects or home improvement. Aluminum profiles are versatile and can be easily customized and fabricated to fit various applications. They are lightweight, durable, and resistant to corrosion, making them suitable for a wide range of projects such as shelving, framing, furniture, and even outdoor structures like pergolas or fences. Additionally, aluminum profiles are available in different shapes and sizes, allowing for flexible and creative designs.

- Q:What are the different installation methods for aluminum profiles?

- There are several different installation methods for aluminum profiles, depending on the specific application and requirements. 1. Screwed Installation: This is one of the most common methods for installing aluminum profiles. It involves using screws to attach the profiles to the desired surface. The profiles typically have pre-drilled holes to facilitate this process. Screwed installation provides a secure and stable connection, making it suitable for various applications. 2. Welded Installation: In some cases, aluminum profiles are welded together to create a strong and seamless joint. This method is commonly used in structural applications where high strength and rigidity are required. Welded installation can provide a more permanent and durable connection, but it requires specialized equipment and expertise. 3. Bolted Installation: Bolted installation involves using bolts and nuts to connect aluminum profiles. This method offers flexibility as it allows for easy disassembly and reassembly if needed. Bolted installation is commonly used in applications where frequent adjustments or modifications are required. 4. Adhesive Installation: Adhesive installation involves using specialized adhesives or bonding agents to attach aluminum profiles to the desired surface. This method is particularly useful when a seamless and aesthetically pleasing finish is desired, as it eliminates the need for visible screws or fasteners. Adhesive installation is commonly used in applications such as interior design, signage, and display systems. 5. Clamped Installation: Clamping is another method for installing aluminum profiles, especially in applications where a non-permanent connection is required. Clamps or brackets are used to secure the profiles in place, allowing for easy adjustment or removal. Clamped installation is commonly used in applications such as exhibition booths, temporary structures, or modular systems. It is important to consider the specific requirements of the project and consult with professionals or manufacturers to determine the most suitable installation method for aluminum profiles. Factors such as load-bearing capacity, aesthetics, ease of installation, and maintenance should be taken into account to ensure a successful installation.

- Q:What is the tolerance of aluminum profile extrusion?

- The minimum wall thickness of the profile is only 0.4 mm, and the tolerance requirement is + 0.04mm.. The extrusion production process is very strict with the equipment, tooling and process requirements. This extrusion technique is often referred to as precision extrusion.1. Examples of precision aluminum extrusionThere are a number of small precision aluminum profile tolerances than JIS standards in the special class of less than half of the tolerance, general precision aluminum requirements of the dimensional tolerance between 0.04 to + 0.07mm.Potentiometer for precision aluminum section "]" profile weight 30 g / m, section size tolerances for precision aluminum profile + 007 mm. loom for "-", section size tolerance is + 0.04mm, the deviation angle less than 0.5 degrees, the bending degree is 0.83 * L.A1050, A1100, A3003, A6061, A6063 (low strength alloy) small precision extrusion the minimum wall thickness of 0.5mm, 20mm2.A5083, A2024, minimum basal area (A7075, medium and high strength Aluminum Alloy) small precision extrusion minimum wall thickness is 0.9mm, the minimum area of 110mm2.Examples of dimensional tolerances for precision aluminium profilesDimension /mm tolerance allowance /mmJIS special grade, small, preciseA 2.54 + 0.15 + 0.07B 1.78 + 0.15 + 0.07C 3.23 + 0.19 + 0.07

- Q:What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- 5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Aluminum Wafer with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords